Mulching film recycling device

A recycling device and mulch technology, applied in collectors, agriculture, applications, etc., can solve problems such as non-continuous work, hanging, easy entanglement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

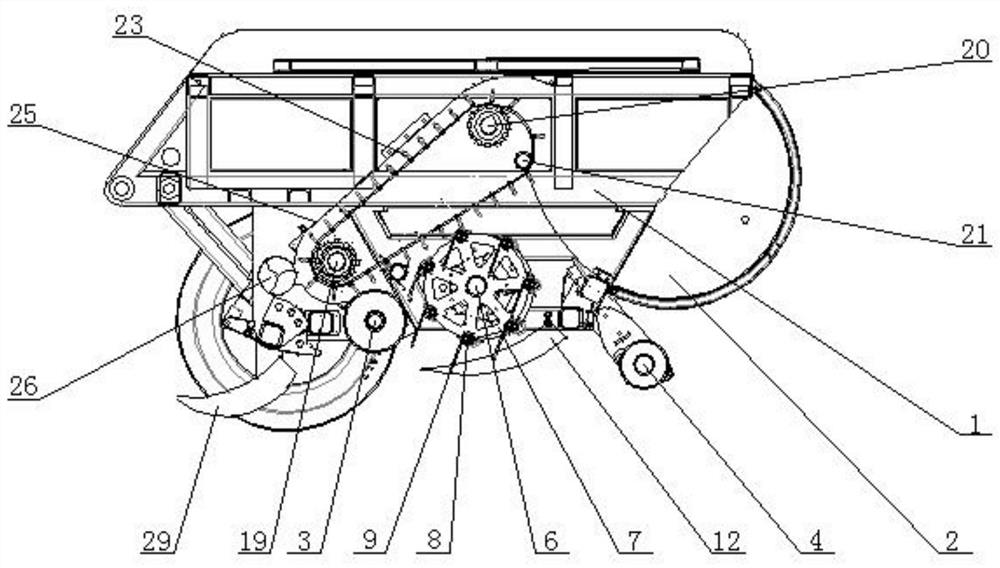

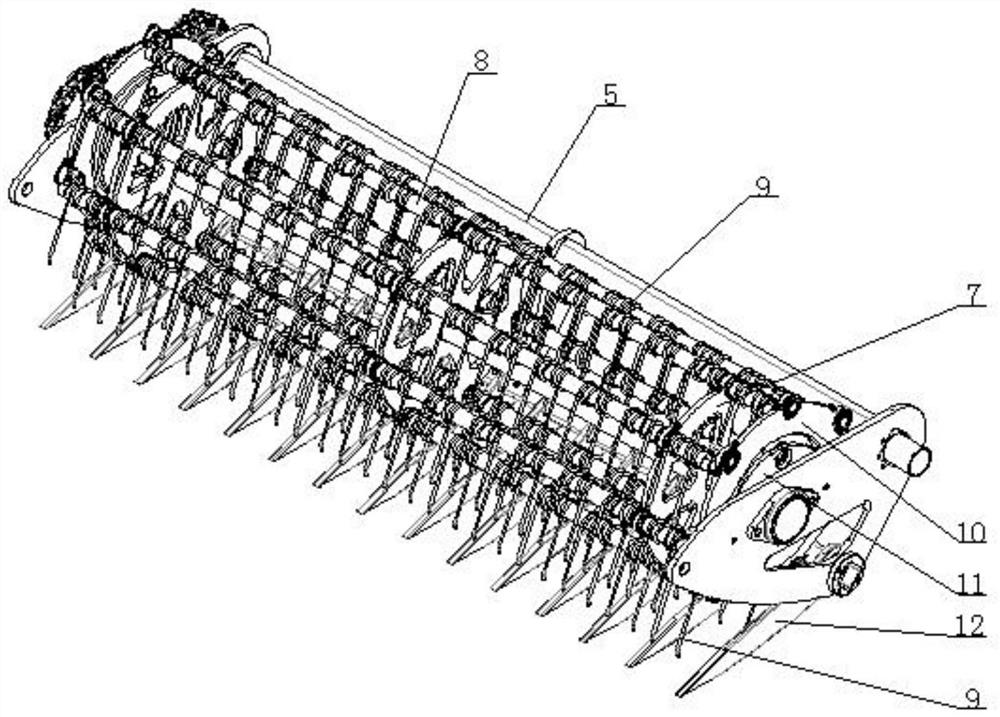

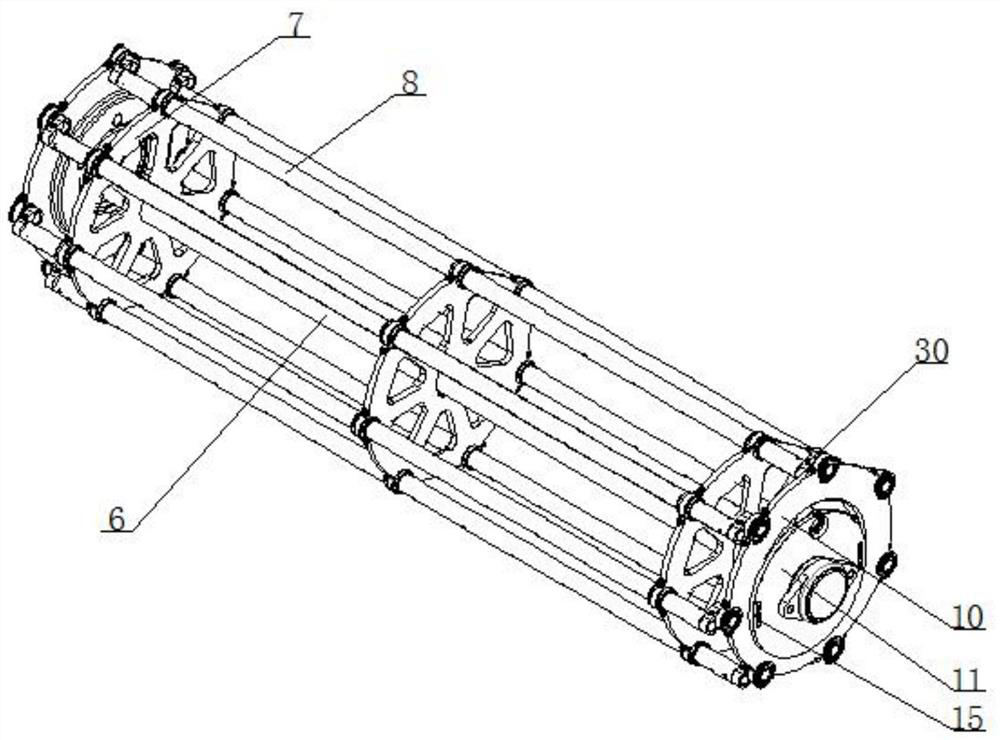

[0031] The plastic film recovery device is composed of a frame 1, a residual film conveying tooth rake and a film collecting box 2. The frame 1 is provided with a film pick-up roller. , spring teeth 9, follower disc 10 and eccentric disc 11, the main shaft 6 is installed on the assembly frame 5 through the bearing seat, the main shaft 6 is evenly distributed with the driving disc 7, the circumference of the driving disc 7 is evenly installed with springs through the bearings The tooth shaft 8, the spring tooth shaft 8 is evenly distributed with spring teeth 9, the spring teeth 9 are torsion springs made of elastic steel bars, and the straight rods at both ends form elastic rods; the elastic rods are in a plane, and the elastic rods Its end is bent to prevent its end from being inserted into the residual film during operation, so as to achieve the purpose of not only lifting the residual film, but also preventing the elastic rod from being inserted into the residual film; the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com