Coal gasification synthesis gas desulfurization device and method

A desulfurization device and a technology for synthesis gas, which are applied in chemical instruments and methods, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of low desulfurization accuracy, high operation energy consumption, and improve the difficulty of production control, and achieve desulfurization accuracy. And the effect of constant sulfur capacity and sufficient desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

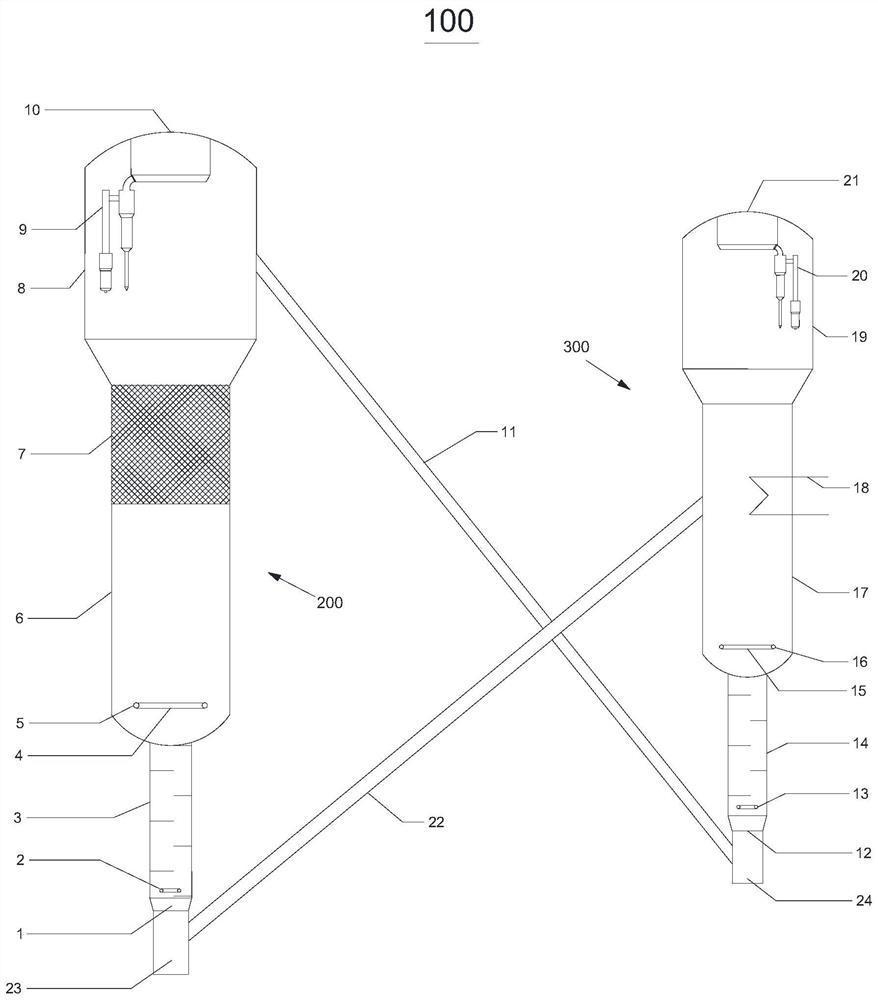

Method used

Image

Examples

experiment example

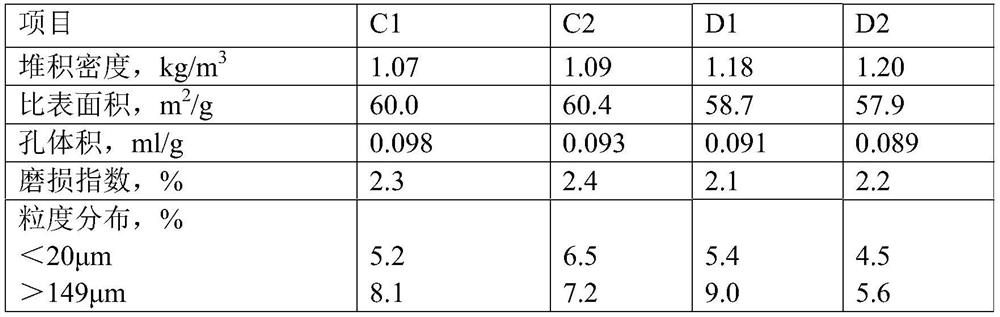

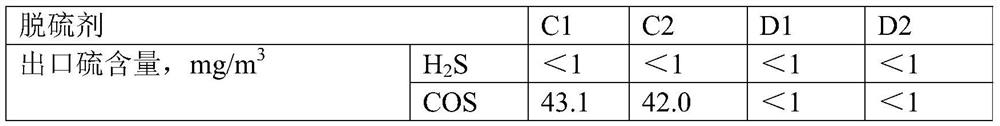

[0114] (1) utilize fixed bed fluidized bed test device to simulate the method provided by the invention to carry out the desulfurization, oxidation, reduction test of desulfurizer;

[0115] (2) The diameter of the dense-phase area of the reactor in the fluidized bed test device is 0.042m, the height of the dense-phase area is 0.4m, and the desulfurizer loading capacity is 200g;

[0116] (3) The gas composition of the reduction reaction prepared in the experiment: H 2 25v%, CO 25v%, CO 2 25v%, H 2 O25v%, gas flow rate 140ml / s (under standard conditions), reduction temperature 400°C, reduction time 60 minutes;

[0117] (4) The gas composition of the simulated coal gasification synthesis gas prepared in the experiment for desulfurization reaction: H 2 25v%, CO25v%, CO 2 25v%, H 2 O 25v%, H 2 S1800mg / m 3 , COS200mg / m 3 , the gas flow rate is 140ml / s (under standard conditions), and the desulfurization reaction temperature is 400°C;

[0118] (5) The desulfurizer is regen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com