Volatile organic product preparation method

A volatile organic, product technology, applied in the field of biochemical industry, can solve problems to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

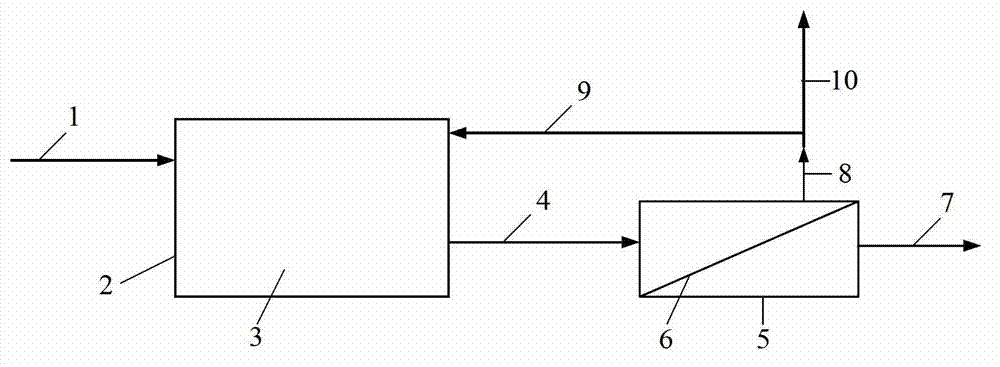

Method used

Image

Examples

Embodiment 1

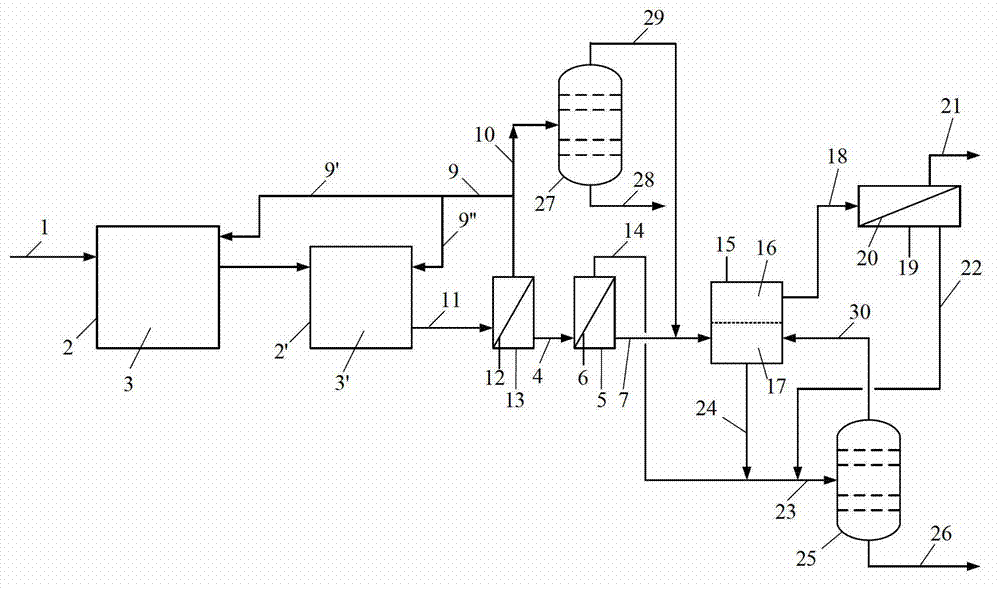

[0043] Production process such as Figure 4 As shown, three fermenters (3, 3' and 3") are cascaded for continuous fermentation process. Feed stream 1 contains 27% glucose and 0.2% non-fermentable matter (mainly mineral salts) with a flow rate of 1000kg / h. The total fermentation volume of the three fermenters is 40m 3. The microorganisms used are genetically engineered yeasts of the genus Arxula disclosed in European patent application EP 11161243.8 (such as Arxula adeninivorans ATCC 76597). When the fermentation process reaches a steady state, the last stage fermenter (fermenter 3") contains 4% n-butanol, 4% yeast cells and about 0.3% non-fermentable matter. Stream 11 is taken from the bottom of fermenter 3". out, enter the membrane separator 13, and obtain the retentate 8 and the permeate 4 after being filtered by the ultrafiltration membrane 12. The permeate 4 further enters the membrane separator 5 and is separated by the lipophilic pervaporation membrane 6 to obtain th...

Embodiment 2

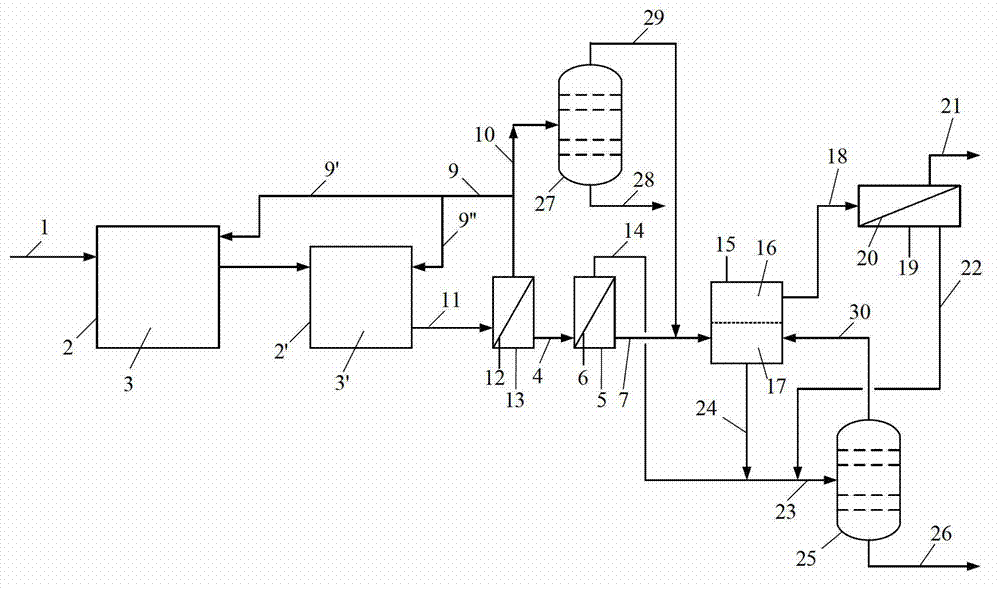

[0045] Production process such as Figure 5 shown. Continuous fermentation using a cascade of three fermenters (3, 3’ and 3”) with a total fermentation volume of 40m 3 . Feed stream 1 contained 27% glucose and 0.2% non-fermentable matter (mainly mineral salts) and had a flow rate of 1700 kg / h. The target product is ethanol, and the microorganism used is Saccharomyces cerevisiae. When steady-state fermentation is achieved, the concentration of ethanol in the third-stage fermenter 3" is 9-10%, the concentration of yeast cells is 6%, the concentration of non-fermentable substances is about 0.3%, and almost all glucose is converted into ethanol. Fermenter 3 "The bottom is produced stream 11 with about 3200kg / h flow rate. Stream 11 flows into ultrafiltration membrane separator 13 and is separated into retentate 8 and permeate 4 by ultrafiltration membrane 12 . The retentate 8 mainly contains water, yeast cells, and macromolecular non-fermentable substances, while the permeate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com