Downward pressing type sealing device

A sealing device and sealing film technology, used in measuring devices, fluid tightness testing, transportation and packaging, etc., can solve the problems of unsatisfactory sealing effect, cumbersome operation, time-consuming and labor-intensive, etc., to improve the degree of automation and efficiency, Conducive to the effect of efficient execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

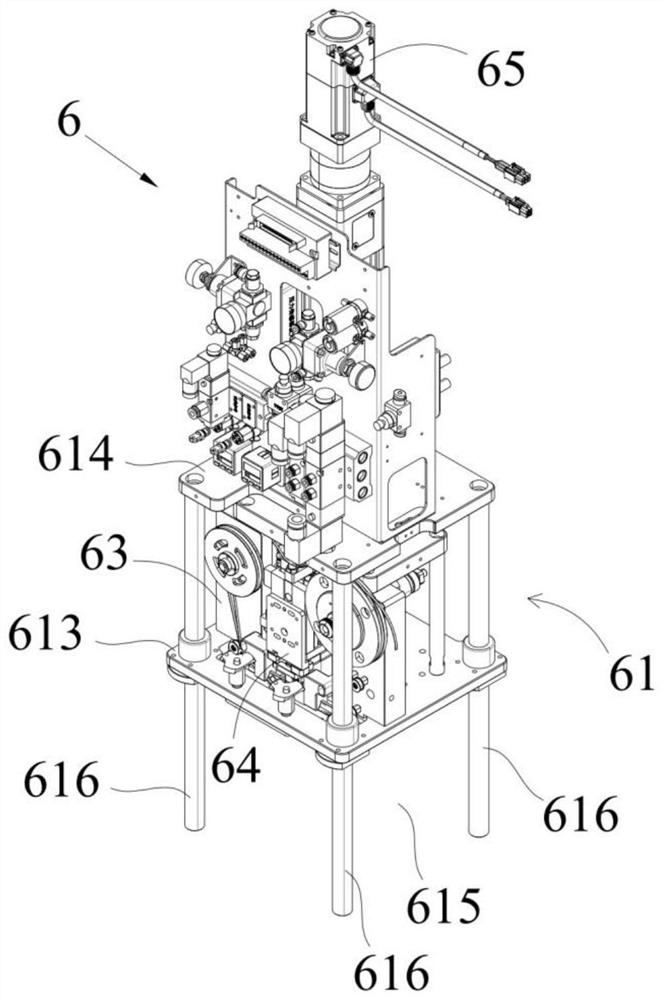

[0047] Figure 1 ~ Figure 4 Embodiment 1 of the present invention is shown, combined with Figure 1 ~ Figure 4 From the illustration, it can be seen that the push-down sealing device 6 includes:

[0048] The installation bracket 61, the installation bracket 61 includes at least three non-collinear lifting guide columns 616, a downward pressure mounting plate 613 that is movably socketed on the lifting guide columns 616 and fixed on the lifting guide columns 616 The fixed installation plate 614, the press-down installation plate 613 is located below the fixed installation plate 614 and spaced apart from the fixed installation plate 614 to form an installation space between the two, the press-down installation plate 613 A workpiece positioning space 615 is formed directly below;

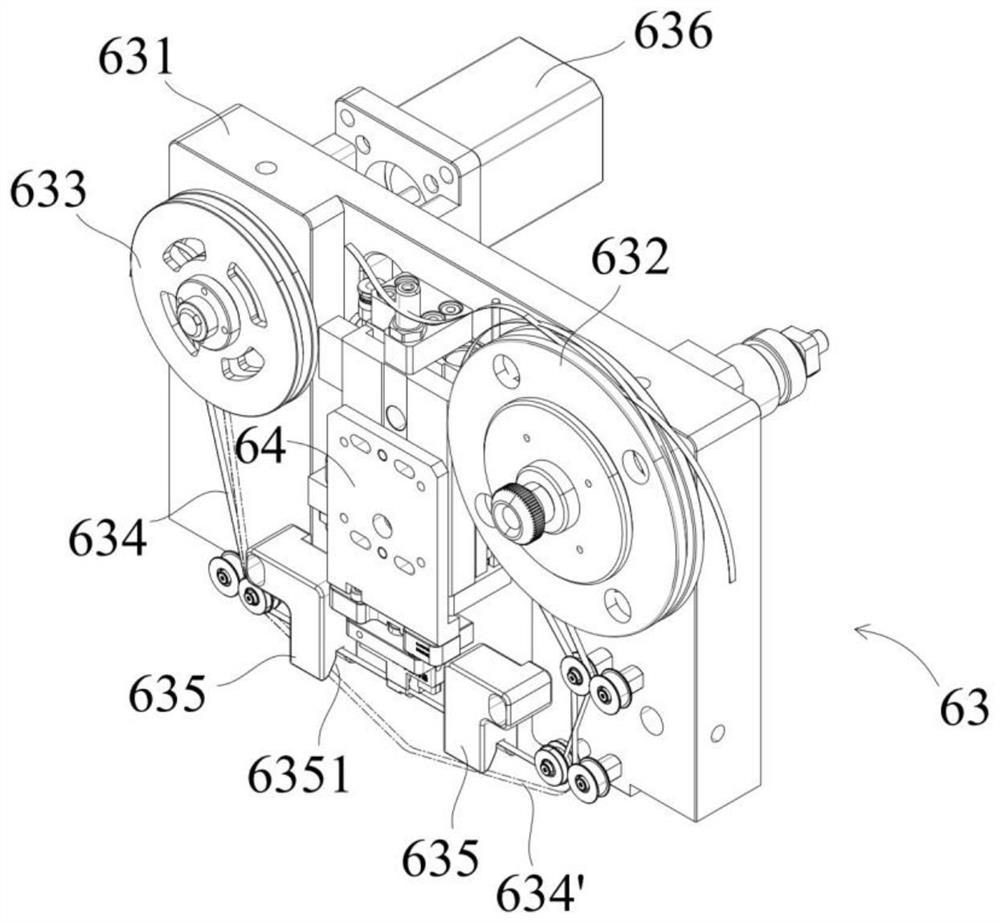

[0049] The bonding module 63 installed on the press-down mounting plate 613 and located in the installation space, wherein a press-down sealing mechanism 64 is fixedly installed; and

[0050] The li...

Embodiment 2

[0068] Figure 3 ~ Figure 6 Also shows embodiment 2 of the present invention, the difference between embodiment 2 and embodiment 1 is:

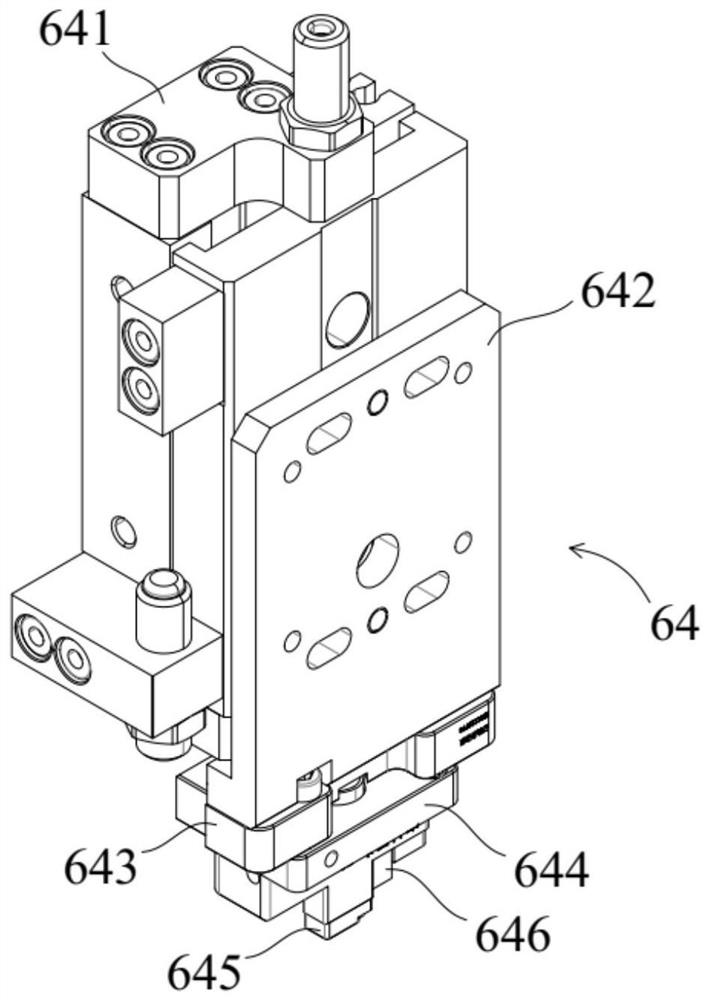

[0069] The sealing head assembly includes:

[0070] The mounting base 644 slidably connected to the bottom of the indenter mounting plate 643 has a mounting portion 6442 hanging downwards from the bottom thereof, and an indenter accommodating groove 6445 with an open bottom is formed in the mounting portion 6442; and

[0071] The sealing pressure head 645 fitted in the pressure head accommodation groove 6445;

[0072] Wherein, a replacement opening 6446 communicating with the outside is opened on the side of the pressure head accommodation groove 6445, and the sealing pressure head 645 enters and exits the pressure head accommodation groove 6445 through the replacement opening 6446 to complete the sealing pressure head 645 installation and replacement.

[0073] refer to image 3 At least two buffer slots 6441 are opened in the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com