Method for processing hot melt adhesive waste products into raw material

A hot-melt adhesive and raw material technology, applied in plastic recycling, recycling technology, etc., can solve problems such as air pollution, molecular structure damage, and toxic gases that are uncomfortable to humans, and achieve the effect of convenient grinding and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

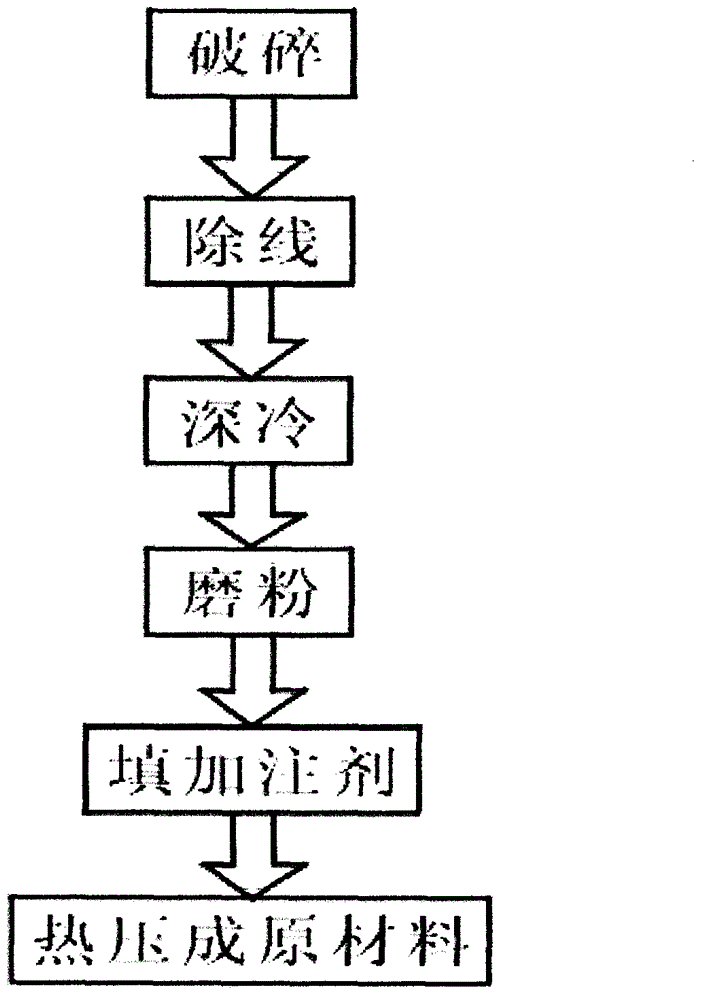

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

[0017] from figure 1 It can be seen from the figure that the first step after recycling hot melt adhesive waste is crushing, that is, crushing the recovered hot melt adhesive waste into less than 20 cm; The thread of the hot-melt adhesive waste less than one centimeter is separated from the hot-melt adhesive, and basically only the pure hot-melt adhesive waste material is retained. The thread removal step can be manually removed, but the efficiency of manual thread removal is relatively low. If you want to improve the efficiency, you can also Delineation can be carried out by using a delineation machine; then enter the cryogenic step, add liquid nitrogen to the hot melt adhesive after crushing and delineation, and let the hot melt adhesive be cryogenically below -145°C to make it brittle;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com