Technology and system for recycling solvent oil from oil gas of butadiene prepared from butane under oxidative dehydrogenation effect

A technology of oxidative dehydrogenation and solvent oil, applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as endangering human health, generating safety hazards, energy waste, etc., and achieves elimination of safety hazards, simple operation, The effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

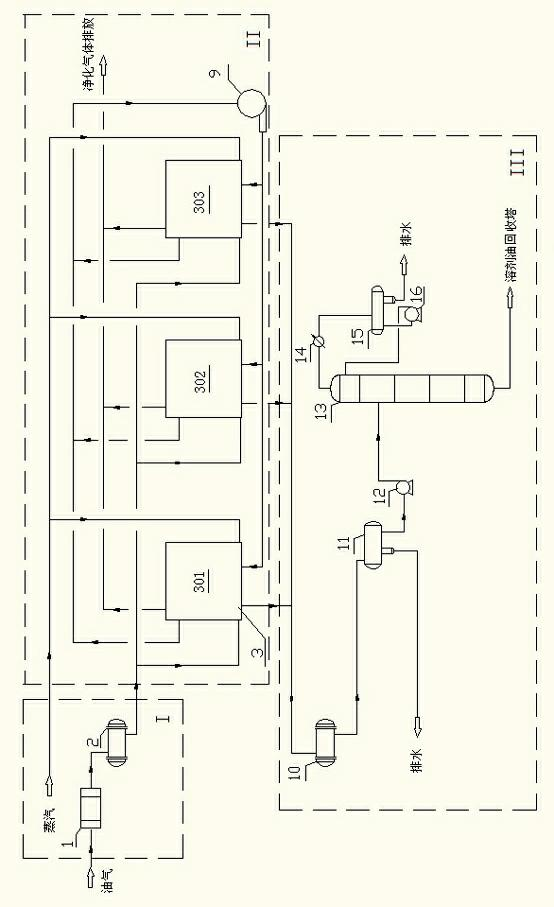

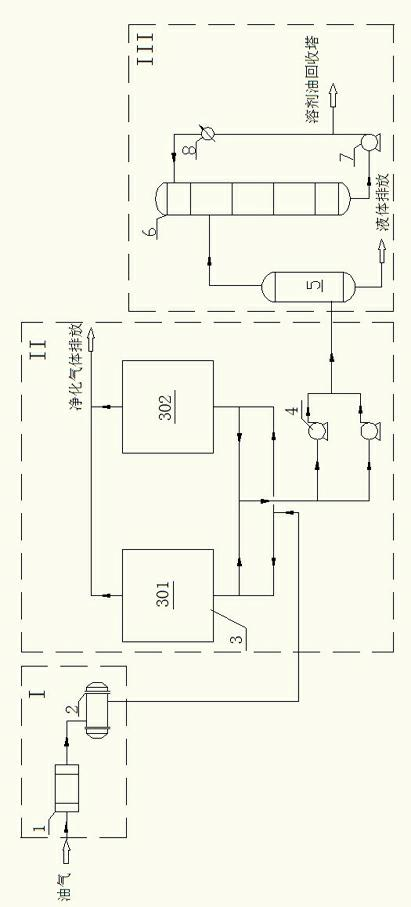

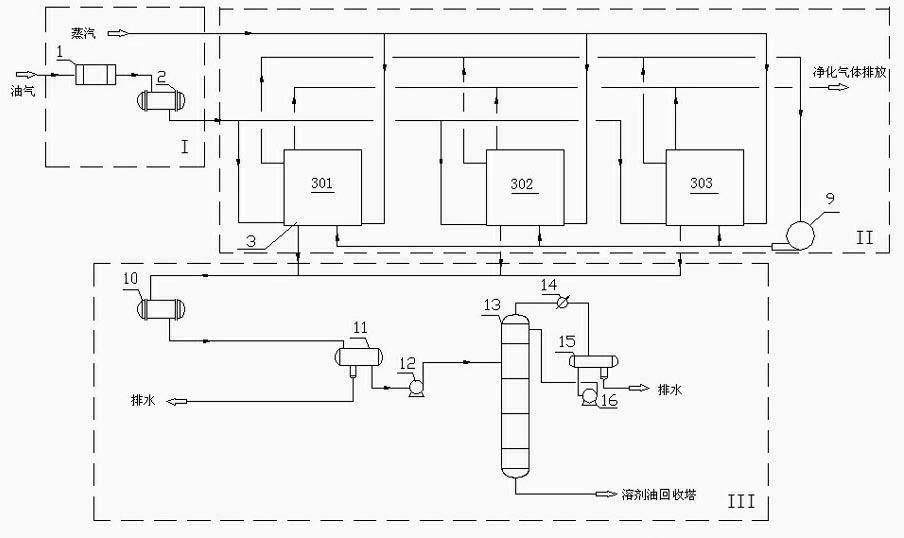

[0027] Such as figure 1 As shown, the vacuum desorption recovery system for solvent oil in butadiene oil gas produced by oxidative dehydrogenation of butene includes a pretreatment system I, an adsorption / desorption system II and a recovery device III. The pretreatment system I includes an oil-gas precision filter 1 and an oil-gas cooler 2; the adsorption / desorption system II includes an adsorption / desorption device 3 and a vacuum pump 4, and the adsorption / desorption device 3 consists of a built-in adsorbent Composed of adsorber I301 and adsorber II302, adsorber I301 and adsorber II302 cooperate with vacuum pump 4 to alternately perform adsorption and desorption; the recovery device III includes a gas-liquid separation tank 5, a solvent oil absorption tower 6, and a solvent oil absorption tower The solvent oil circulating pump 7 connected at the bottom of the 6 towers, the solvent oil circulating cooler 8 arranged between the solvent oil circulating pump 7 and the solvent oil...

Embodiment 2

[0037] The adsorbent in Example 1 is replaced by carbon fibers, and the process is the same as in Example 1.

Embodiment 3

[0039] The adsorbent in Example 1 is replaced by silica gel, and the process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com