A dust removal and filtering device and method

A technology of filtering device and filtering method, applied in separation methods, dispersed particle filtering, chemical instruments and methods, etc., can solve the problems of blockage of filter elements, high filtering pressure difference, poor filter recoil regeneration effect, etc. The effect of reducing maintenance cost, avoiding secondary dust and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

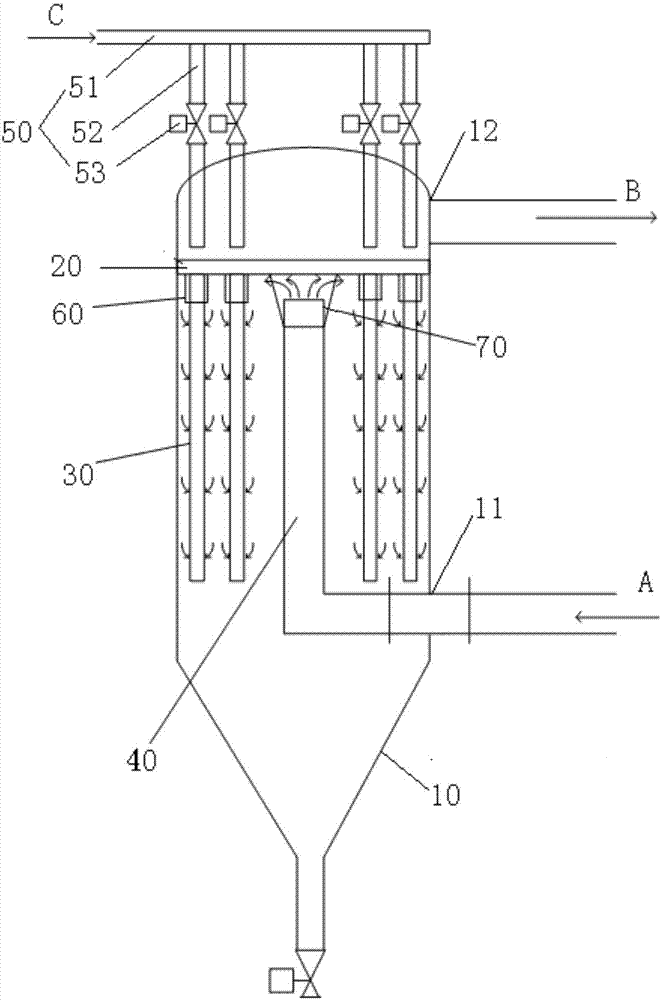

[0033] Embodiment 1 discloses a dust removal and filtering device, comprising: a casing, an air inlet and an air outlet are arranged on the casing, the air inlet is arranged at the lower end of the casing, and the air outlet is arranged at the upper end of the casing; A plate, the tube plate is provided with at least one through hole, the tube plate is arranged inside the shell, and is located between the air inlet and the air outlet of the shell; at least one filter element, the filter element is arranged inside the shell and is located Below the through hole of the tube sheet, its upper end is fixed on the tube sheet; the air intake pipe extends through the air inlet of the shell to the inside of the shell, and the air outlet of the air intake pipe is located below the tube plate; The blowing structure and the back blowing structure are arranged above the tube sheet, and the air outlet direction of the back blowing structure faces the through hole of the tube sheet.

[0034]...

Embodiment 2

[0037] Compared with embodiment one, the improvement of embodiment two is that the blowback structure in the dust removal and filtering device disclosed in embodiment two includes a main pipeline and a plurality of sub-pipes, and the sub-pipes are fixed on the main pipeline and connected with the main pipeline Each sub-pipe has a blowing port, the blowing port faces the through hole on the tube plate, and each sub-pipe is provided with a valve. Specifically, a filter element is correspondingly provided below each blowing port of the sub-pipe.

[0038] The subpipes in the backflushing structure of the dust removal filter device in this embodiment are correspondingly provided with a filter element, and a subpipe and its corresponding filter element are a partition, and when backflushing is required, only one partition can be backflushed , it is also possible to perform back-flushing on a plurality of partitions, which can effectively improve the application flexibility of the dust...

Embodiment 3

[0041] Compared with the first embodiment, the improvement of the third embodiment is that the dust removal and filtering device disclosed in the third embodiment also includes: a plurality of wear-resistant sleeves, the wear-resistant sleeves are set on the filter element, and are located on the filter element upper end.

[0042] Specifically, the height of the anti-wear sleeve is equal to the distance between the upper end surface of the intake pipe and the lower end surface of the tube sheet; the inner diameter of the anti-wear sleeve is 2 to 5 mm larger than the outer diameter of the filter element; The blue connection is fixed on the tube plate, which can effectively improve the installation stability of the anti-wear sleeve and further improve its protection effect on the filter element.

[0043] Due to the high flow rate and high dust concentration of the gas to be filtered at the air outlet of the intake pipe, the upper end of the filter element near the intake pipe is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com