A conveying experimental device for measuring the pneumatic conveying performance of expanded graphite bulk materials

A technology of pneumatic conveying and expanded graphite, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of lack of technical basic data, etc., and achieve the effects of simple equipment structure, reduced production costs and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

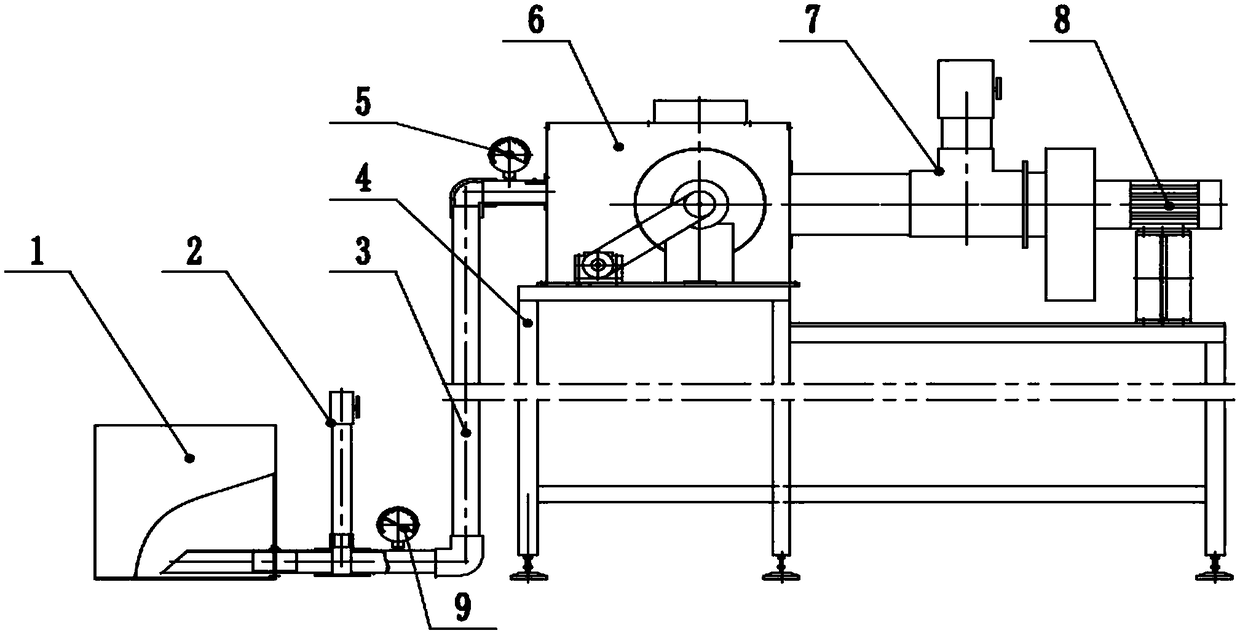

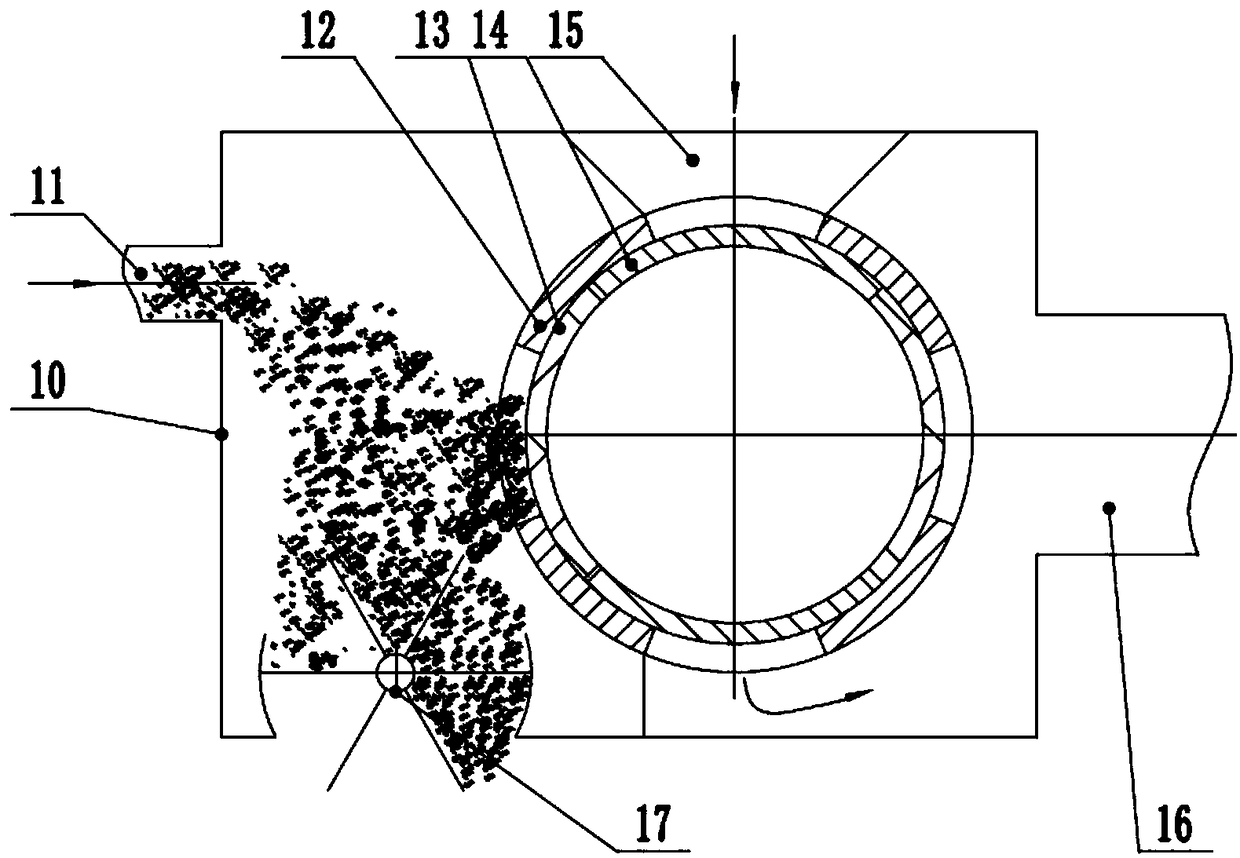

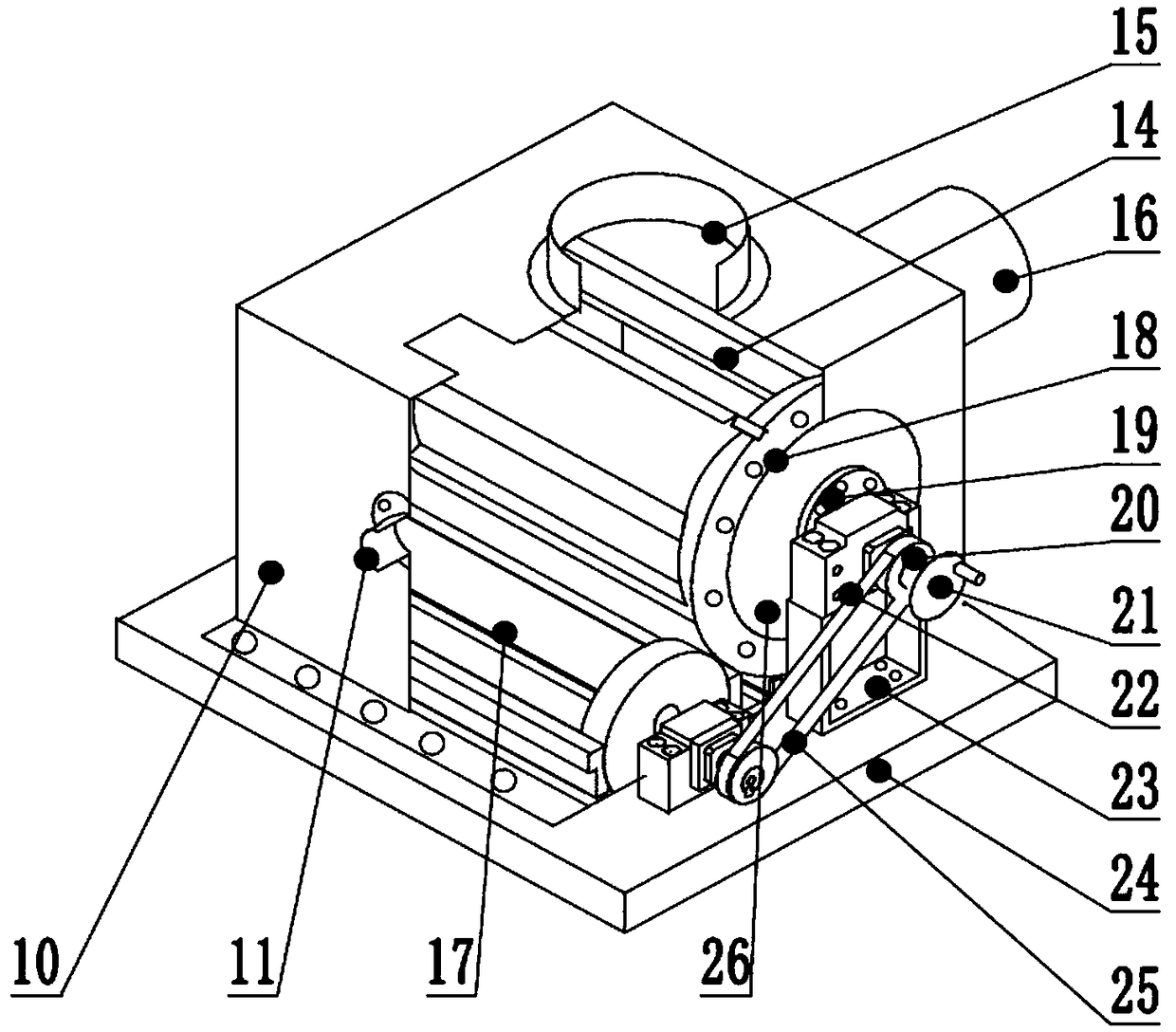

[0015] A kind of conveying experiment device of the pneumatic conveying performance measurement of expanded graphite bulk material of the present invention, figure 1 Shown is the overall layout of the experimental platform. The experimental device includes a hopper 1, a gas-solid separator 6, a negative pressure fan 8, a delivery pipeline 3, and an adjustment and detection device 7. The delivery pipeline 3 is connected to the hopper 1 and the gas-solid separation by bolts. device 6, and a mixing proportional valve 2 and a first negative pressure gauge 9 are provided at the connection hopper 1, and a second negative pressure gauge 5 is set on the right side of the inlet of the gas-solid separator 6 connected to the delivery pipeline 3, and the gas-solid separation The right air outlet of the device 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com