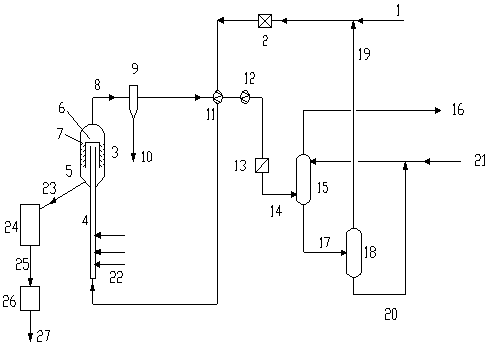

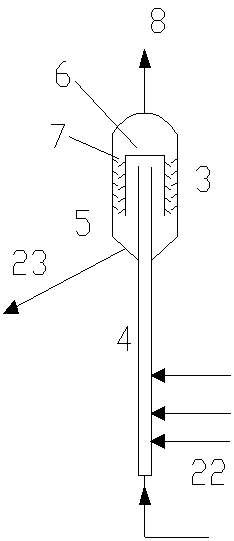

A hydrogen production process method and system

A process method and technology of a pyrolysis reactor are applied in the field of hydrogen production in the process of acid gas treatment, which can solve the problems of low decomposition rate and low hydrogen equilibrium concentration, and achieve the advantages of improving conversion rate, realizing gas-solid separation, and reducing processing load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Treat raw gas H 2 S concentration 100%, flow 4000Nm 3 / h; the particle size of Fe powder is 1-3mm, and the Fe powder is preheated to 800°C before entering the reactor; the absorption tower uses N-methyldiethanolamine as the absorbent. After the feed gas passes through the pyrolysis reactor, H 2 S generates H 2 The conversion rate is 31%, and the absorption tower top gas flow rate is 1235Nm 3 / h, H 2 The purity is 100%.

Embodiment 2

[0051] Treat raw gas H 2 The S concentration is 100%, the flow rate is 4000Nm3 / h; the Fe powder particle size is 1-3mm, and the Fe powder is preheated to 900°C before entering the reactor; the absorption tower uses N-methyldiethanolamine as the absorbent. After the feed gas passes through the pyrolysis reactor, H 2 S generates H 2 The conversion rate is 37%, and the absorption tower top gas flow rate is 1450Nm 3 / h, H 2 The purity is 100%.

Embodiment 3

[0053] Treat raw gas H 2 The concentration of S is 100%, the flow rate is 4000Nm3 / h; the particle size of Fe powder is 1-3mm, and the Fe powder is preheated to 1000°C before entering the reactor; the absorption tower uses N-methyldiethanolamine as the absorbent. After the feed gas passes through the pyrolysis reactor, H 2 S generates H 2 The conversion rate is 45%, and the absorption tower top gas flow rate is 1780Nm 3 / h, H 2 The purity is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com