Powder selecting and collecting device

A technology of powder selection and powder pipe, which is applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., can solve the problems of increasing loss along the pipeline, increasing system energy consumption, and powder selection efficiency Influence and other issues, to achieve the effect of improving powder selection and powder collection efficiency, reducing energy consumption, and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

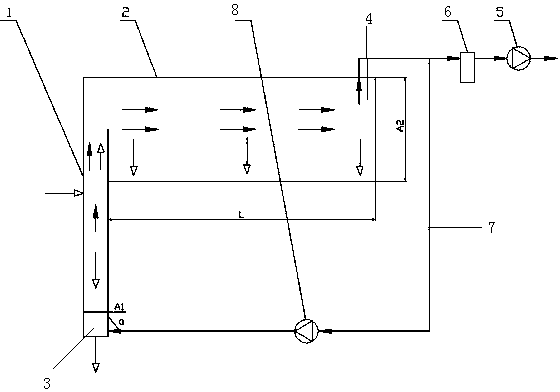

[0047] The device for selecting powder and collecting powder according to the present invention, its structure is shown in figure 1 , it can be seen from the figure that the device includes a powder selection tube 1 and a powder collection tube 2, a feed inlet is set on the upper part of the powder selection tube (as shown by the arrow in the left middle of the powder selection tube in the figure), and a discharge is set at the lower end Inlet and air inlet 3, the powder selection tube 1 is set perpendicular to the horizontal plane, that is to say, the angle α between the axial direction of the powder selection tube 1 and the horizontal plane is equal to 90°; the powder collection tube 2 is set horizontally, the collection The powder pipe 2 communicates with the top of the powder selection pipe 1 and seals the top of the powder selection pipe 1. The powder collection pipe 2 is provided with an outlet at the end far away from the powder selection pipe 1. The air outlet 4 is con...

Embodiment 2

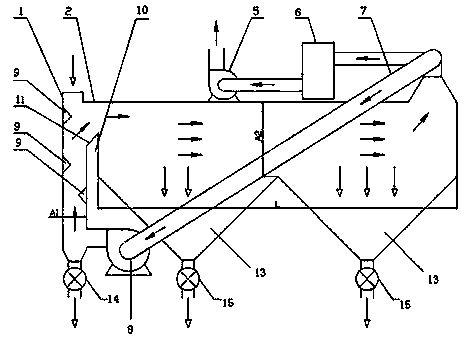

[0054] The device for selecting and collecting powder according to the present invention can also be further provided with one or more guide angles staggered on the inner wall of the powder selecting tube 1 on the basis of the structure of the device described in Embodiment 1, The guide angle is inclined towards the side of the air inlet 3 towards the direction away from the air inlet 3 (see figure 2 shown). As can be seen from the figure, the guide angle 9 is set to an equilateral triangle, and the adjacent two sides between the adjacent guide angles 9 are parallel; as a transformable embodiment, the setting of the guide angle 9 can also be selected as long as it meets The side of the guide angle 9 facing the air inlet 3 can be inclined towards the direction away from the air inlet 3, and the side of the guide angle 9 away from the air inlet can be set to any shape , the white arrow in the figure indicates the flow direction of the powder, and the black arrow indicates the ...

Embodiment 3

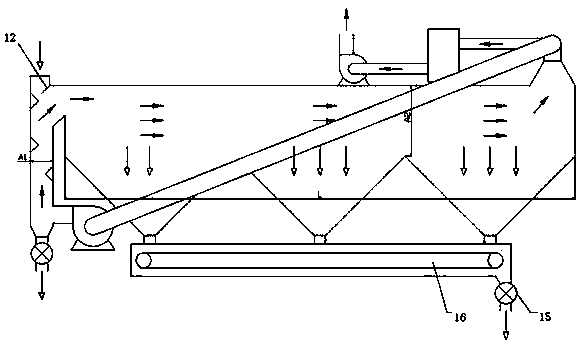

[0058] In the above-mentioned embodiment, the device for selecting powder and collecting powder is directly connected through the connection between the powder selecting pipe 1 and the powder collecting pipe 2; There will be a problem that the material with a low suspension speed will slide into the powder selection tube for repeated winnowing, which will affect the powder selection efficiency. For this reason, the powder selection and powder collection device described in this embodiment is formed with a transition slide section 10 at the connection between the powder selection pipe 1 and the powder collection pipe 2, see image 3 As shown, the white arrow in the figure indicates the flow direction of the powder, and the black arrow indicates the flow direction of the air flow. The top of the transition slide section 10 is a slope 11, and the slope 11 is from one end close to the powder selection tube 1 to close to the One end of the powder collection pipe 2 rises gradually; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com