Ultrafine pulverizing and grading device for capsule drug and technical method thereof

A technology of ultra-fine pulverization and classification device, applied in the direction of cyclone device, grain processing, etc., can solve the problems of complex process, one-time meeting requirements, difficult pulverization fineness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

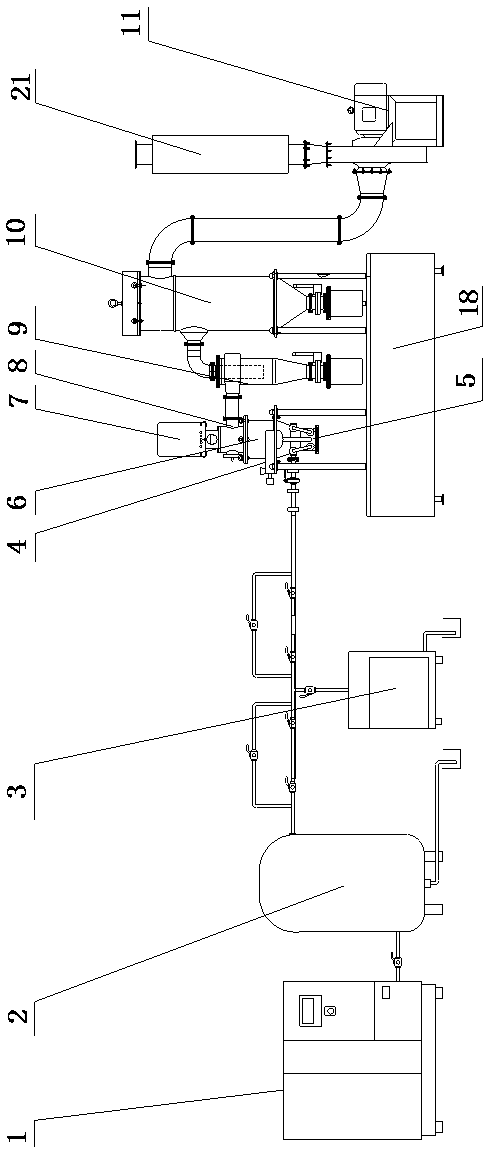

[0033] See figure 1 , A device for ultrafine pulverization and classification of capsule drugs, comprising an air source system, an ultrafine pulverization mechanism connected with the air source system, a classification mechanism connected with the ultrafine pulverization mechanism, and a collection mechanism connected with the classification mechanism,

[0034] The air source system includes an oil-free air compressor 1, an air storage tank 2 connected to the oil-free air compressor, and an air cooling dryer 3 connected to the air storage tank. The air cooling dryer is connected to the crushing mechanism.

[0035] The ultrafine grinding mechanism includes a feeder 4, an ultrafine grinding chamber 5 connected with the feeder, and a discharge port 1 connected with the ultrafine grinding chamber.

[0036] The grading mechanism includes a grading chamber 6, a grading wheel arranged inside the grading chamber, a motor 7 connected to the grading wheel, and a discharge port 8 arranged at t...

Embodiment 2

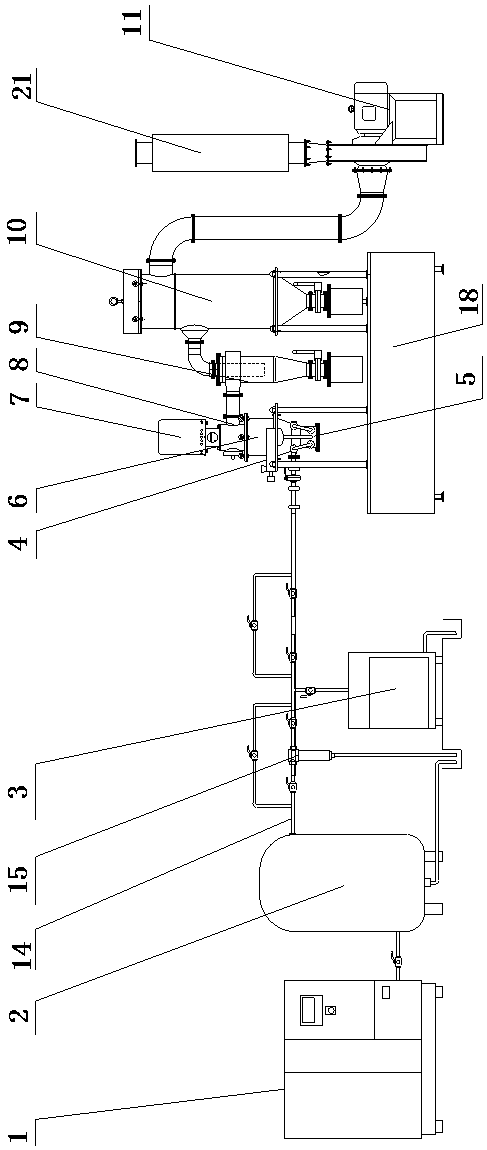

[0048] Refer to figure 1 , This embodiment is a device for superfine pulverization and classification of capsule medicines. The difference from embodiment 1 is:

[0049] The induced draft fan is connected to the muffler 21.

[0050] The induced draft fan adopts the HTD series high-pressure fan, and chooses the axial intake, single-stage cantilever centrifugal blower. The fan has the characteristics of high pressure, large air volume, low noise, stable operation, and long service life. Compared with other fans, it can save 20- 50%, the noise is lower than 75dB, saving various costs by 30-45%. The function of the induced draft fan is to provide suitable and stable centripetal force for the grading mechanism, dissipate heat in time, generate negative pressure in the system, and prevent external leakage of powder.

Embodiment 3

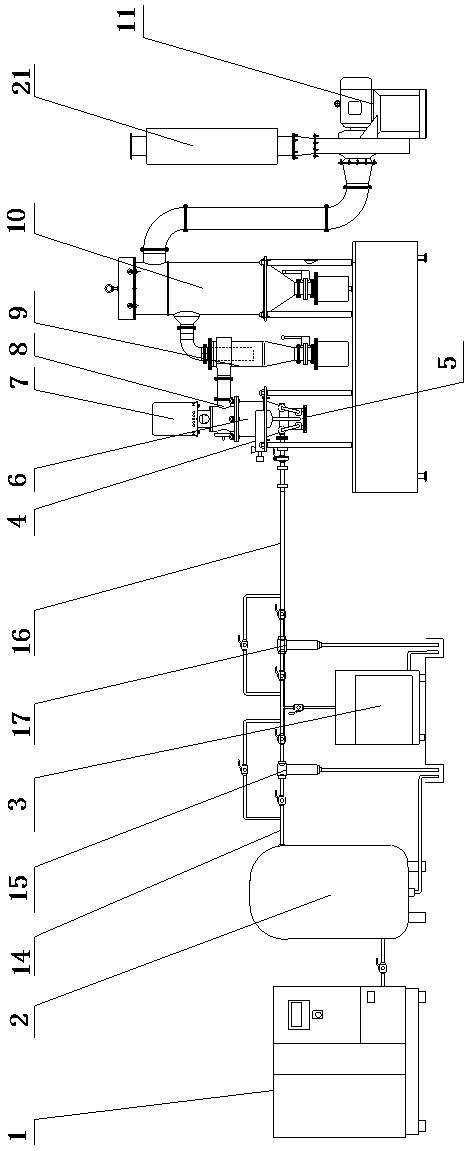

[0052] Refer to figure 2 In this embodiment, a device for superfine pulverization and classification of capsule drugs is an improvement on the basis of embodiment 2, specifically:

[0053] The gas storage tank is connected to the air refrigerating and drying machine through a gas conveying pipe 14 and an air filter 15 is arranged on the gas conveying pipe 1.

[0054] Through the above technical solution, the air can be purified once, and the impurities in the air can be prevented from affecting the cooling and drying efficiency of the air cooling and drying machine.

[0055] According to the actual needs of the present invention, an automatic drain is added to the air filter to remove the condensed water that may be generated at the bottom of the air filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com