Circulation degassing fluidized bed bioreactor

A degassing fluidized bed and bioreactor technology, applied in the field of alcohol fermentation, can solve the problems of particle upflow and backflow, uneven particle distribution, poor degassing effect, etc., to reduce crushing loss and uniform particle distribution , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

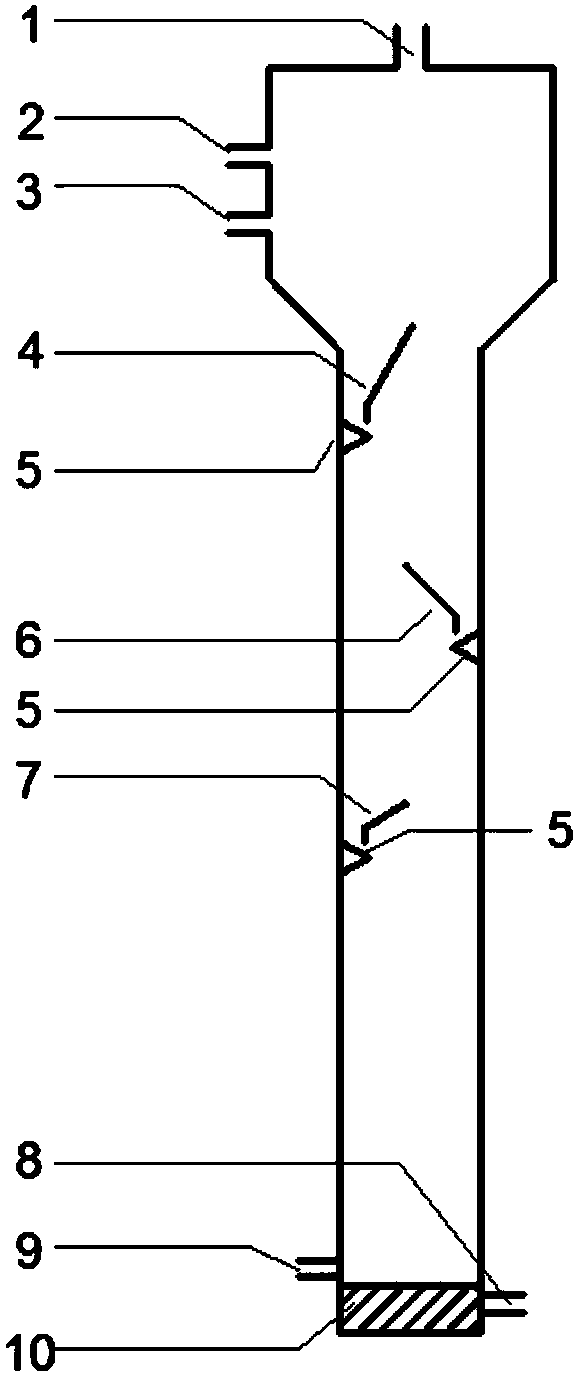

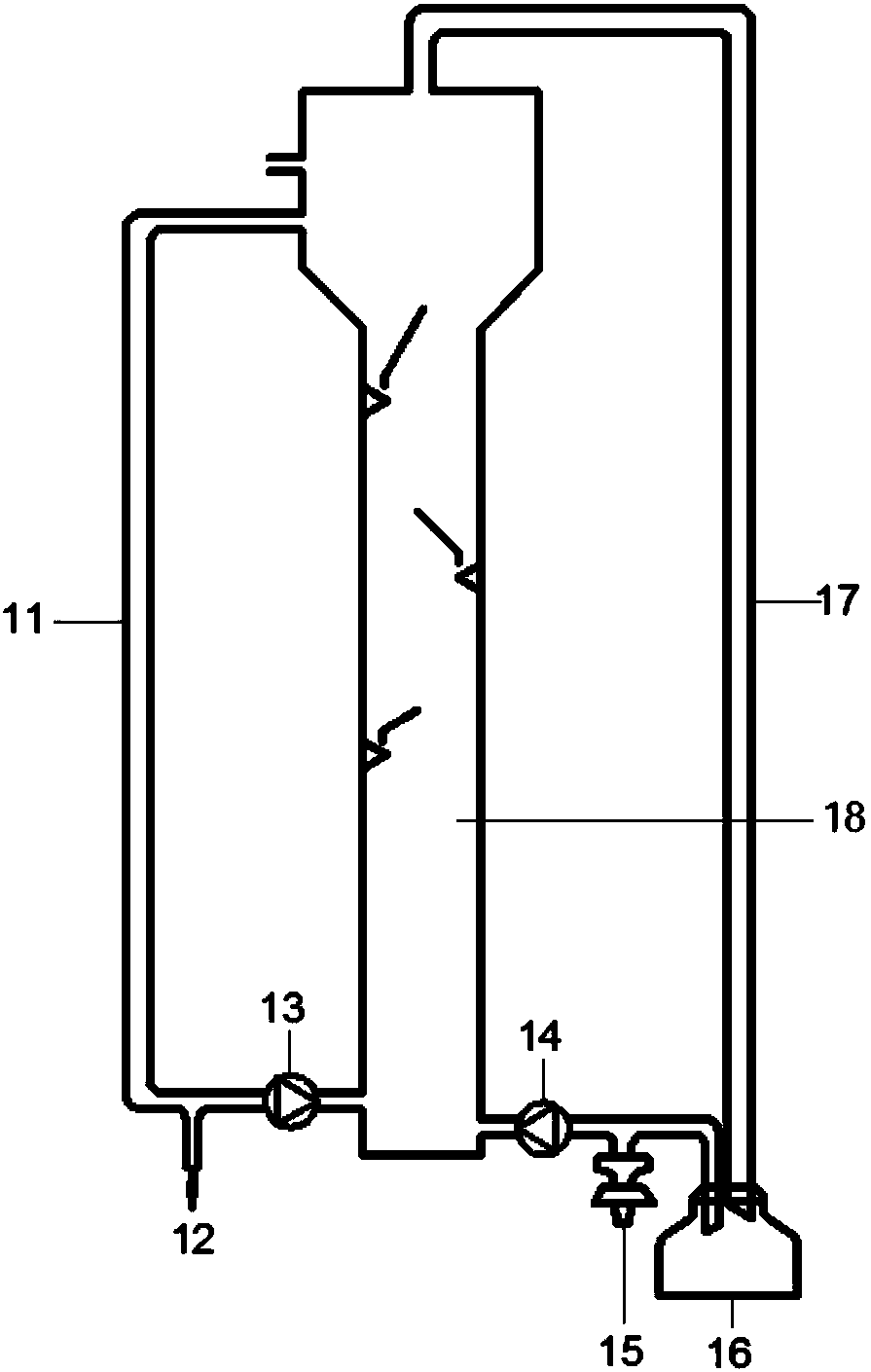

[0028] Such as Figure 1-Figure 2 Shown, the working principle of circulating degassing type fluidized bed bioreactor of the present invention is as follows:

[0029] (1)CO 2 It is aerated into the bottom of the reactor main body 18 from the air chamber, and the fermentation broth is passed into the bottom of the reactor main body 18 under the action of liquid pressure, and the reaction power is formed under the joint action of the two, pushing the fermentation broth and immobilized cells to move upward.

[0030] (2) The immobilized cells are fermented in the fermentation broth to produce bubbles, which are lifted to move upwards and collide with the first-stage baffle 7. Most of the particles realize gas-solid separation, and the particles with slightly larger specific gravity sink and the specific gravity The smaller one rises with the liquid flow and forms a reflux cycle in the first circulation zone.

[0031] (3) Part of the particles that have not been separated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com