Efficient gas-liquid separator

A gas-liquid separator and pre-separator technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effect of improving the passing capacity, reducing the impact, and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

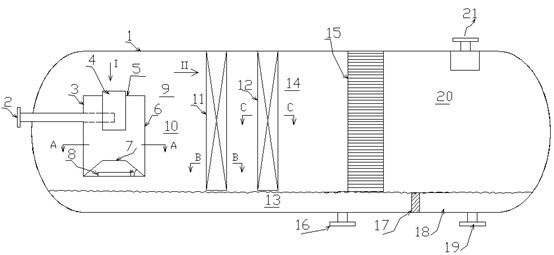

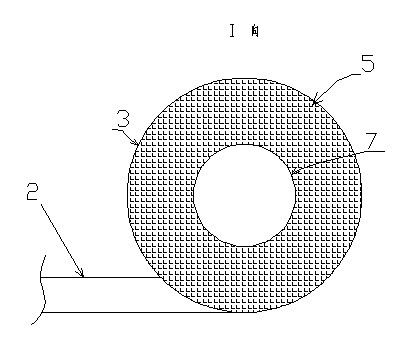

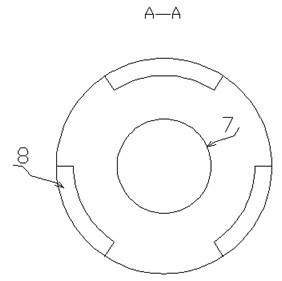

[0039] As shown in the figure, the high-efficiency gas-liquid separator includes a shell 1, a feed inlet 2, a pre-separator 3, an air guide tube 4, a cover plate 5, a swirl tube 6, a circular platform isolation plate 7, a liquid guide tank 8, a gas phase Zone 9, pre-separation zone 10, first layer of vane packing 11, second layer of vane packing 12, liquid phase zone 13, main separation zone 14, wire mesh demister 15, sewage outlet 16, isolation plate 17, collector Liquid chamber 18, liquid outlet 19, dry gas area 20, gas outlet 21;

[0040]The front end of the housing 1 is provided with a feed port 2, the upper part of the rear section of the housing 1 is provided with a gas outlet 21, the lower part of the housing 1 is provided with a sewage outlet 16, and the lower part of the rear end is provided with a liquid outlet 19, and the upper part of the housing 1 is a gas phase area 9. The lower part of the housing 1 is a liquid phase area 13, and the gas phase area 9 in the hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com