Efficient high-speed vapour-liquid mass transfer structure form

A high-speed, vapor-liquid technology, applied in fractionation and other directions, can solve the problems of lower tray efficiency, lower operating capacity upper limit, large tray pressure drop, etc., achieve uniform distribution of vapor and liquid, reduce mist entrainment, mist entrainment small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

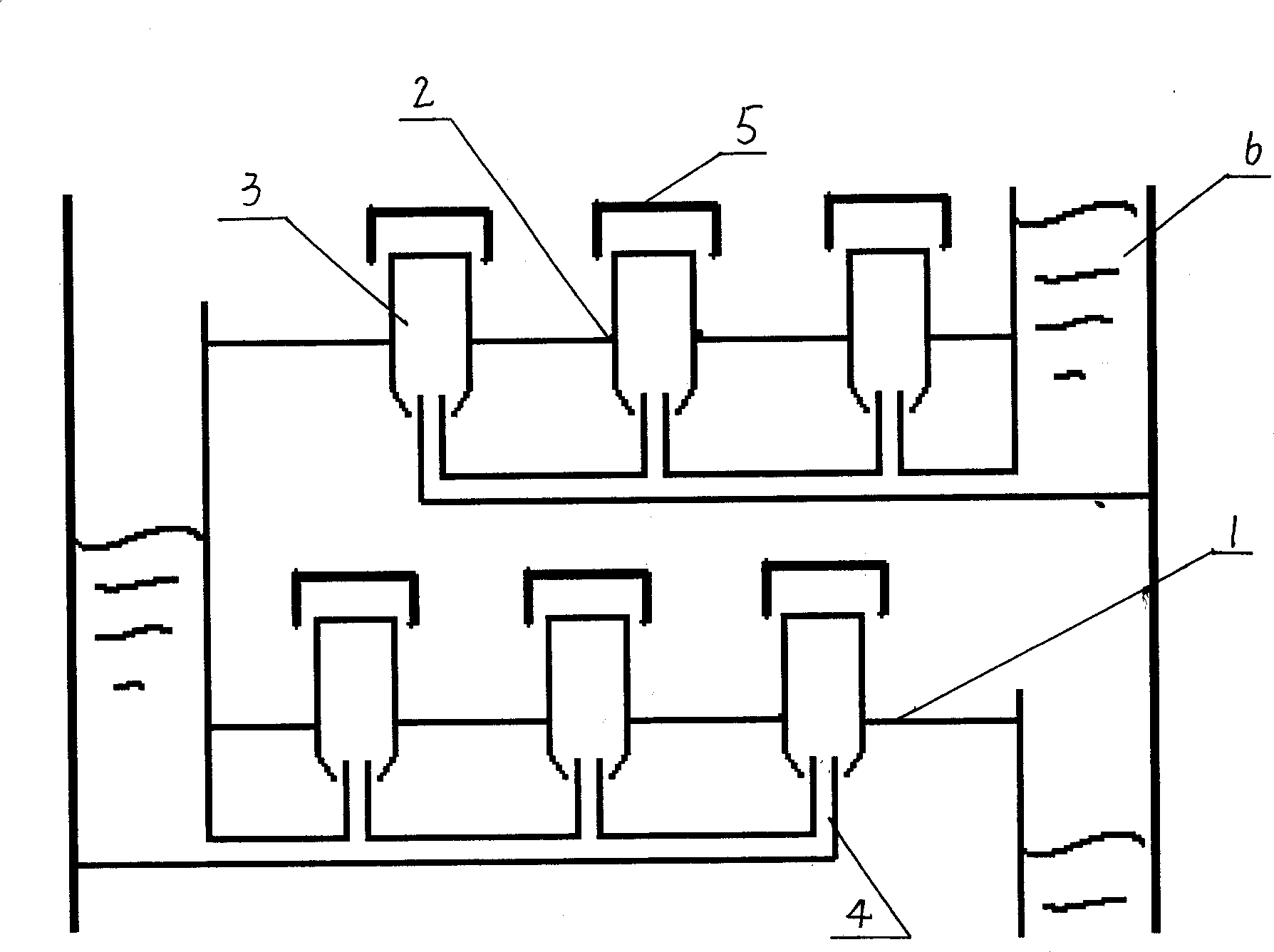

[0032] A high-efficiency and high-speed vapor-liquid mass transfer configuration involved in the present invention is generally installed in a tray tower as shown in the accompanying drawings, and mainly includes a tray 1, a plate hole 2, an air lifter 3, a distribution pipe 4, a top cover 5, a drop The liquid pipe 6, the lifter 3 is installed on the tray 1 through the plate hole 2, the distribution pipe 4 is correspondingly arranged at the lower part of the lifter 3, the top cover 5 is arranged on the top of the lifter 3, the tray 1 and the downcomer 6 Connection, multiple mass transfer elements are connected in parallel on the tray 1, the mass transfer elements are composed of plate holes 2, air lifter 3, distribution pipe 4, top cover 5, the upper part of the air lifter 3 is straight cylindrical, the lower part is a cone bottom, the cone The bottom is below the straight cylinder, the cone bottom has an opening, and a liquid swirl component is installed under the cone bottom....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com