Gas-liquid separator, high temperature regenerator, absorption type refrigerator and absorption type heatpump

A gas-liquid separator and refrigerant technology, used in refrigerators, heat pumps, refrigeration components, etc., can solve problems such as difficulty in adapting to miniaturization requirements, decline in gas-liquid separation performance, and increase in size and shape of gas-liquid separators. Superior gas-liquid separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the same or similar code|symbol is attached|subjected to the same or a similar member in each drawing, and the overlapping description is abbreviate|omitted.

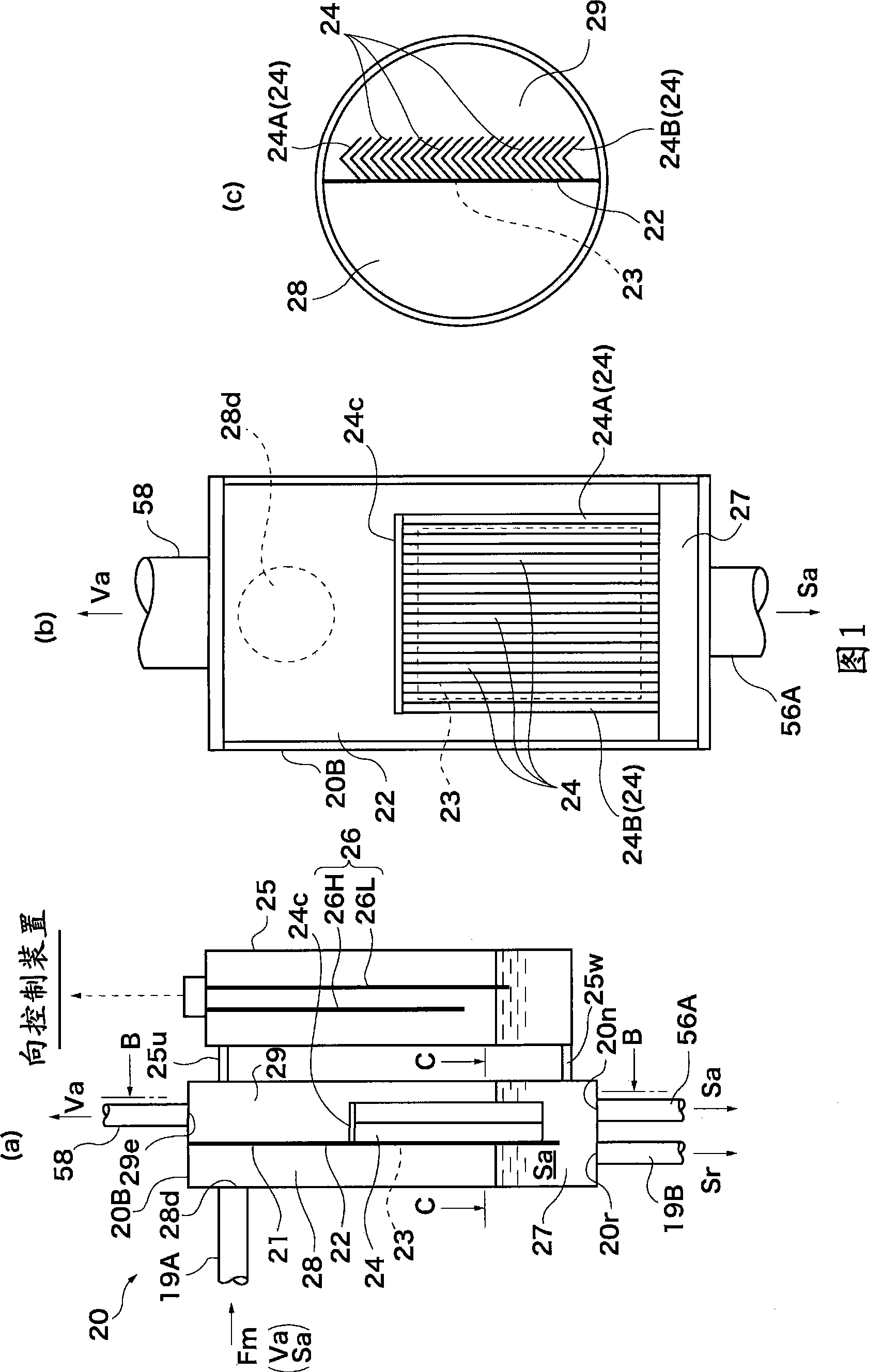

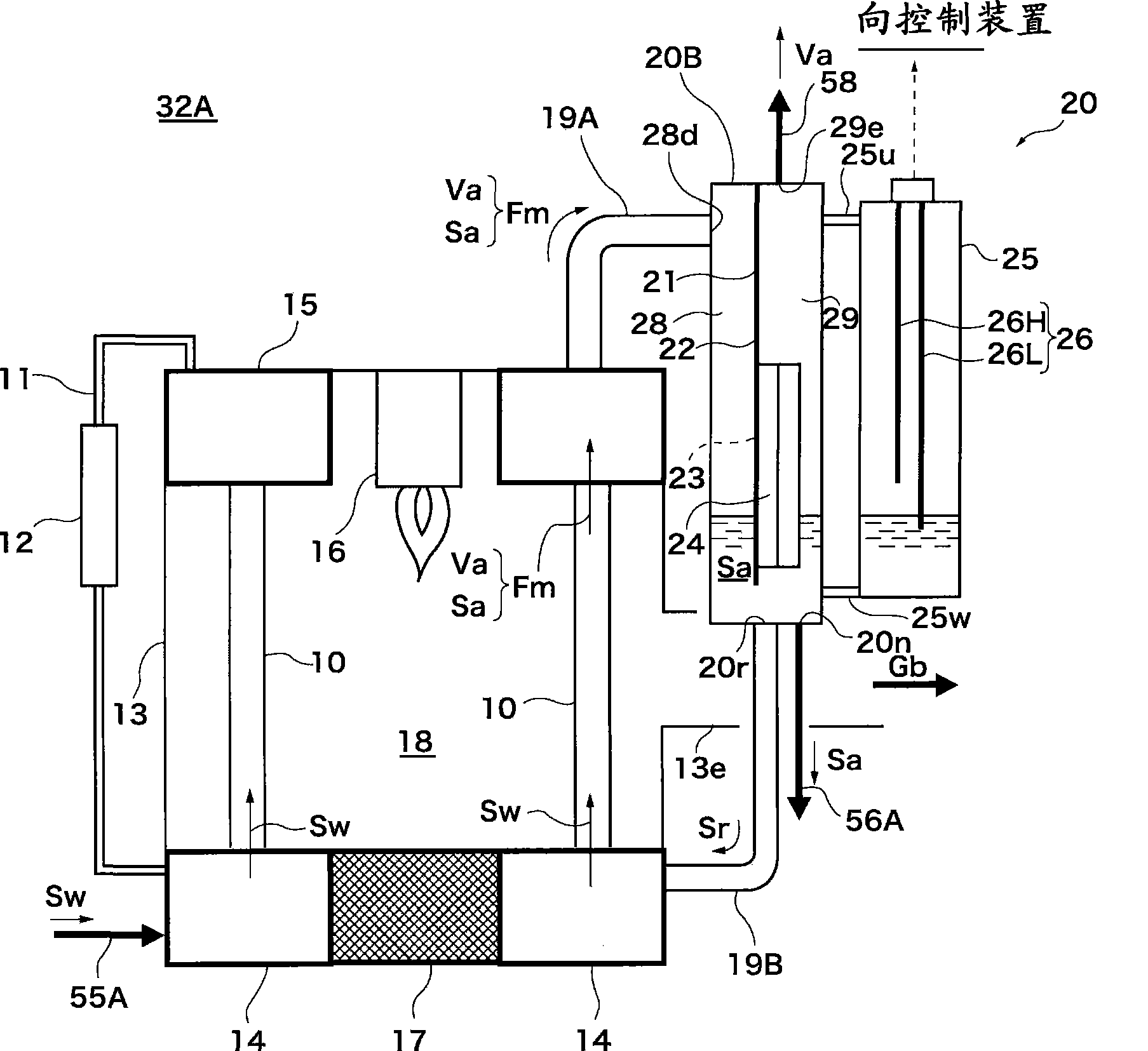

[0031] First, referring to FIG. 1 , the configuration of a gas-liquid separator 20 according to a first embodiment of the present invention will be described. FIG. 1 is a schematic configuration diagram of a gas-liquid separator 20 . Wherein (a) is a schematic longitudinal sectional view, (b) is a B-B view of (a) in Fig. 1 , and (c) is a C-C view of (a) in Fig. 1 . Gas-liquid separator 20 is typically arranged in high temperature regenerator 32A (see figure 2 ).

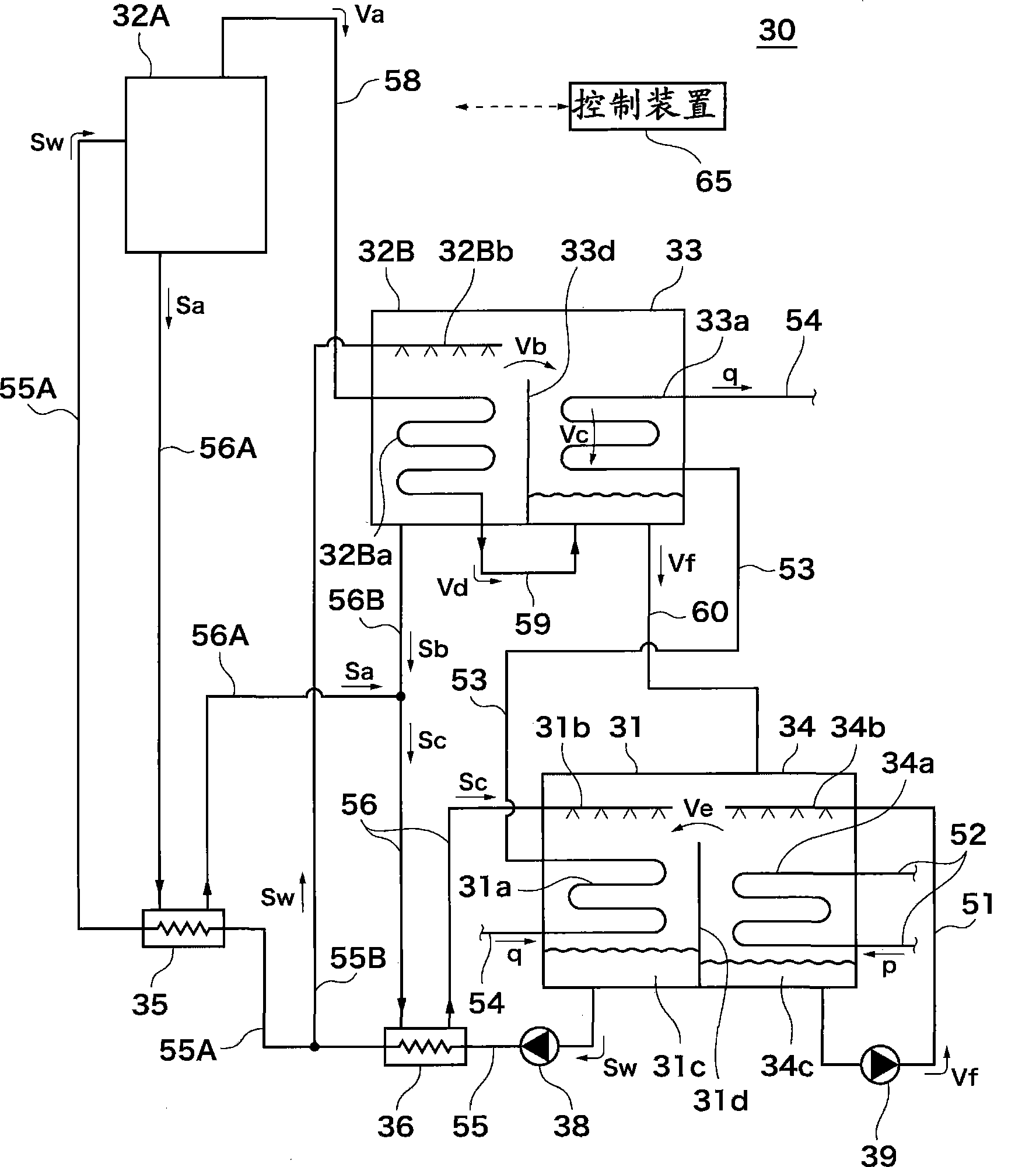

[0032] Gas-liquid separator 20 is in absorption refrigerator 30 (see image 3 ) of high temperature regenerator 32A (see figure 2 ) is a machine that separates the refrigerant vapor Va and the concentrated solution Sa from the mixed fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com