Gas-Liquid Separator and Refrigeration System With Gas-Liquid Seperator

a technology of gas-liquid separator and refrigeration system, which is applied in the direction of refrigerating machines, fluid circulation arrangement, lighting and heating apparatus, etc., can solve the problems of deteriorating performance, disturbing the liquid level, and the level of liquid refrigerant pool, so as to achieve enhanced gas-liquid separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Effects of Embodiment 1

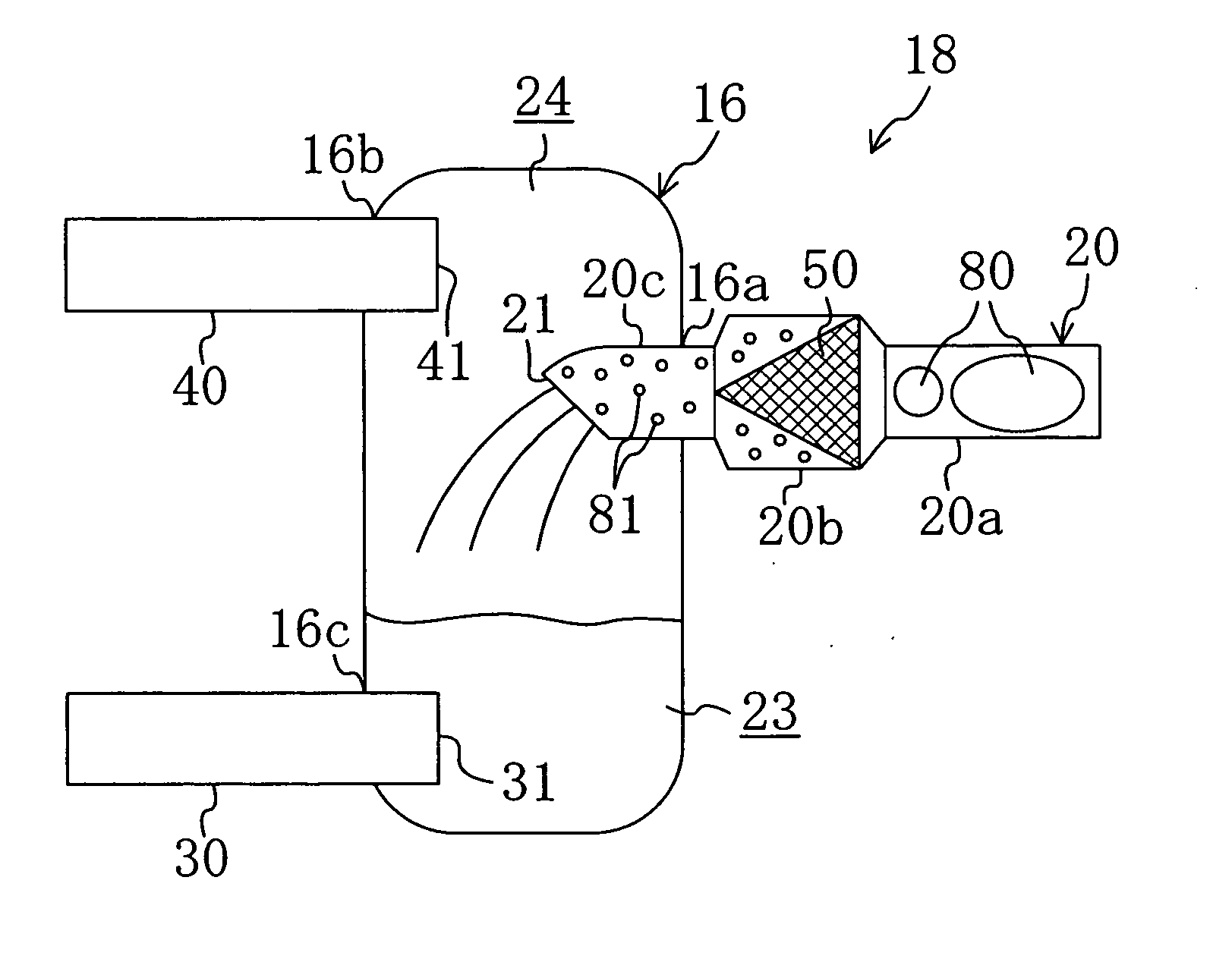

[0100]Since, in the refrigeration system (1), a mesh member (50) is placed in the inflow pipe (20) of the gas-liquid separator (18), gas bubbles (80) of gas refrigerant in gas-liquid two-phase refrigerant flowing through the inflow pipe (20) can surely be fragmentized, whereby the gas-liquid two-phase refrigerant can be homogenized. Thus, the gas-liquid two-phase refrigerant is introduced in a regular and stable flow condition into the vessel body (16). This reduces the disturbance of the liquid level of the pool (23) of liquid refrigerant, the spattering of liquid refrigerant due to the liquid level disturbance, and the mixing of gas bubbles into liquid refrigerant, such as due to bubbling of the pool (23) of liquid refrigerant.

[0101]Furthermore, since the inflow pipe (20) is disposed to horizontally extend over the length thereof, large bubble masses of gas refrigerant in the gas-liquid two-phase fluid are likely to be broken, which restrains the production ...

modification 1

of Embodiment 2

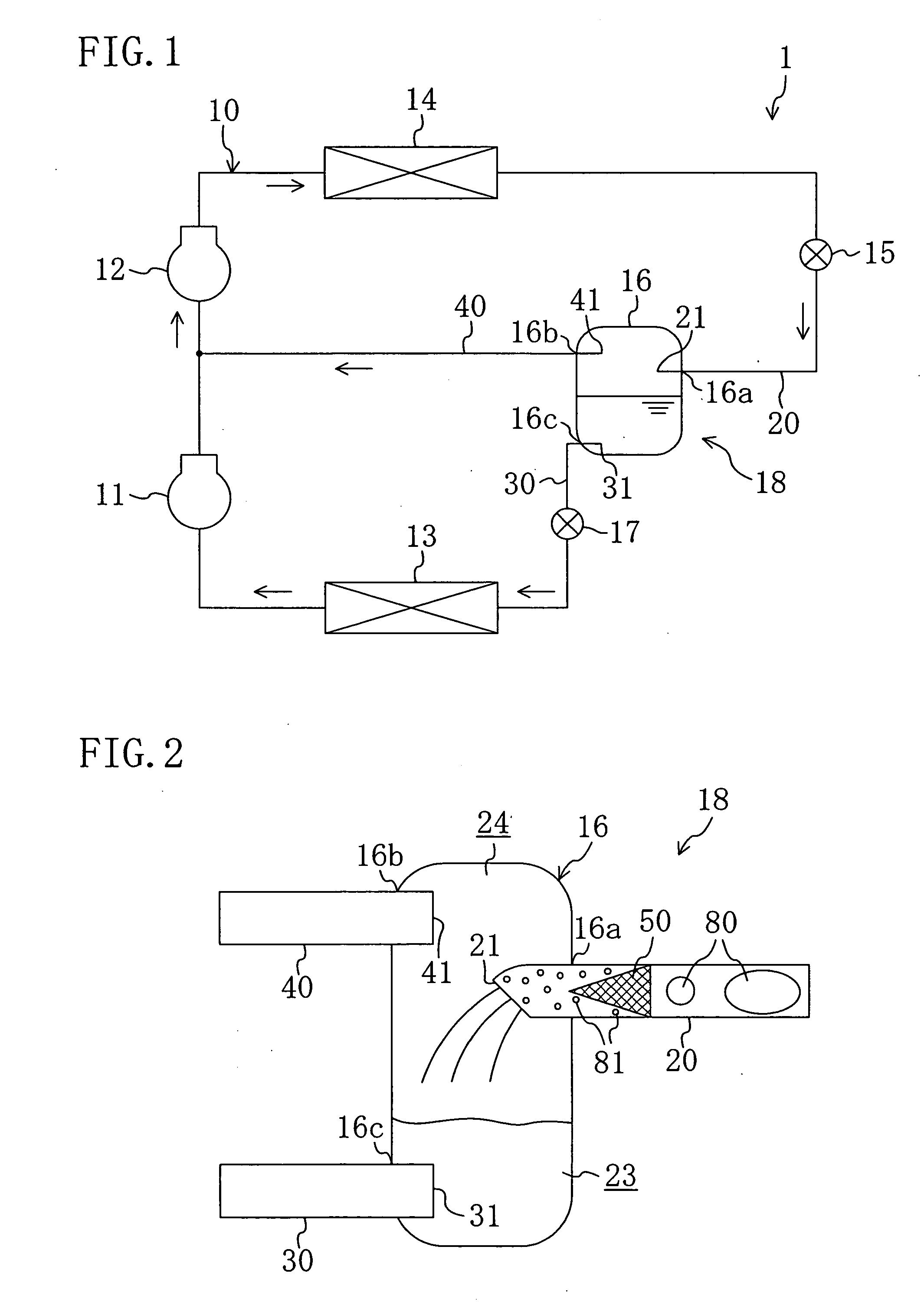

[0129]This embodiment is configured, as shown in FIG. 6, by placing a mesh member (50) in the inflow pipe (20) of the gas-liquid separator (18) according to Embodiment 2.

[0130]According to this embodiment, since the mesh member (50) is placed in the inflow pipe (20), gas-liquid two-phase refrigerant introduced through the inflow pipe (20) into the vessel body (50) is homogenized, whereby the flow condition of the gas-liquid two-phase refrigerant becomes regular and stable. This prevents disturbance of the liquid level of the pool (23) of liquid refrigerant, spattering of liquid refrigerant into the pool (24) of gas refrigerant due to the liquid level disturbance, and mixing of gas bubbles into liquid refrigerant, such as due to bubbling of the pool (23) of liquid refrigerant. Thus, the gas-liquid separation performance of the gas-liquid separator (18) can be further enhanced.

[0131]The rests of the configuration and operational behavior and the other effects are the sa...

modification 2

of Embodiment 2

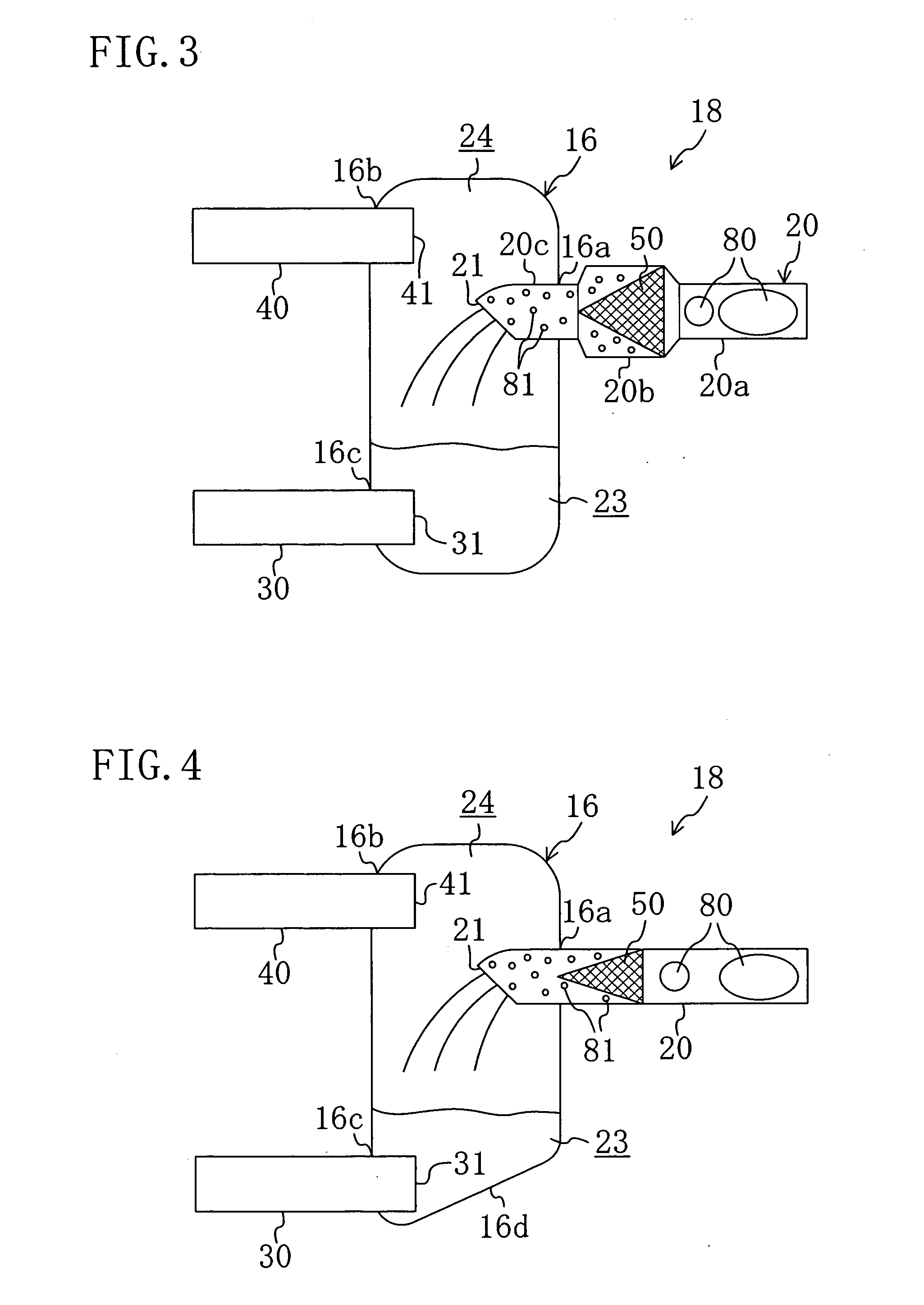

[0132]This embodiment is configured, as shown in FIG. 7, by installing the vessel body (16) of the gas-liquid separator (18) according to Embodiment 2 to incline it downward from its one end surface through which the gas outflow pipe (40) passes towards its other end surface through which the liquid outflow pipe (30) passes. Thus, an under part (16d) of the peripheral surface of the cylindrical vessel body (16) inclines downward towards a point thereof corresponding to the opening end (31) of the liquid outflow pipe (30) and is thereby constituted as the under surface of the vessel body (16). Furthermore, in this embodiment, only the vessel body (16) is placed at an angle but the pipes (20, 30, 40) are horizontally placed in and around the vessel body (16).

[0133]According to this embodiment, the vessel body (16) can surely have a pool of liquid refrigerant around the opening end (31) of the liquid outflow pipe (30) even if the amount of liquid refrigerant therein is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com