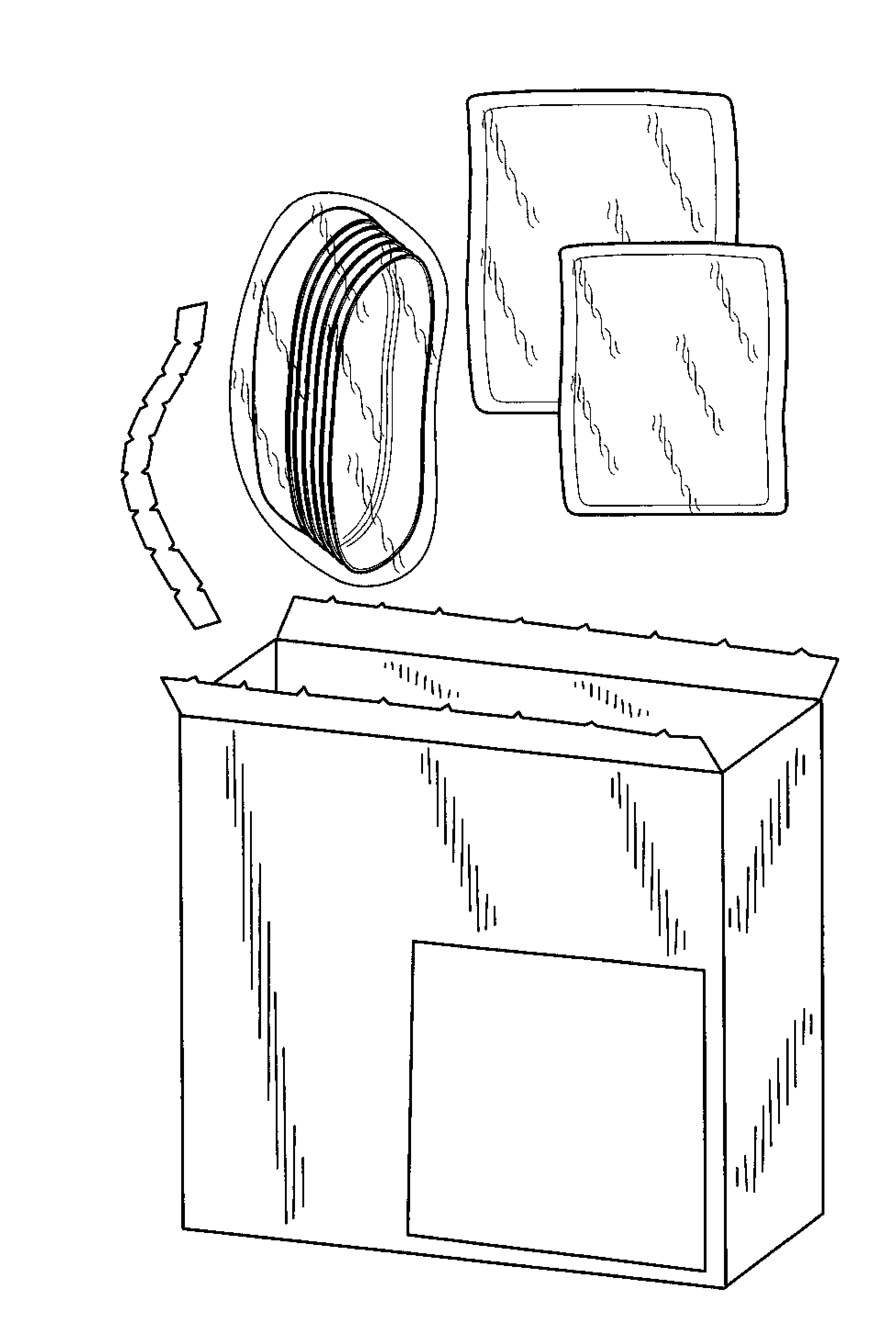

Soft shaped tortillas

a tortilla and soft technology, applied in the field of soft tortilla products, can solve the problems of limited shelf life, high cost, and high production cost, and achieve the effects of preventing decay, reducing production costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0131]

Wheat Tortilla FormulaFormula %IngredientrangesTypical usage levelsWheat flour; 11-13%45-60%45%, 50%, 55%, 60%proteinWater15-30%15%, 20%, 25%, 30%Hydrogenated Vegetable 5-10%5%, 7.5%, 10%fat such as canola,cottonseed, corn, soy,safflower; naturally solidfats such as palm, coconut,Glycerine 0-10%0%, 2%, 4%, 6%, 8%, 10%Salt1-2%1%, 1.5%, 2%Leaveners; Baking0.5-1% 0.5%, 0.6%, 0.7%,powder, baking soda,0.8%, 0.9%, 1%leavening acids such asMCP, SAPP, SALPDough conditioners;0.25-1% 0.25%, 0.5%, 0.75%, 1%Mono-glycerides, Di-glycerides, SSL, L-cysteine, DATEM

example 2

Standard Tortilla Procedure

[0132]1.) Combine ingredients in mixer

2.) Mix 4-10 minutes on medium speed until dough is fully developed

3.) Allow dough to rest five minutes

4.) Divide dough into 40 gram balls

5.) Press dough balls in tortilla press @ 400° F. (˜205° C.) for 1-3 seconds

6.) Bake in tortilla oven @400° F. (˜205° C.) for 30-90 seconds

7.) Cool five minutes on cooling rack

8.) Package tortillas

9.) Final tortilla moisture content of 23-28%, Water Activity at <0.880

example 3

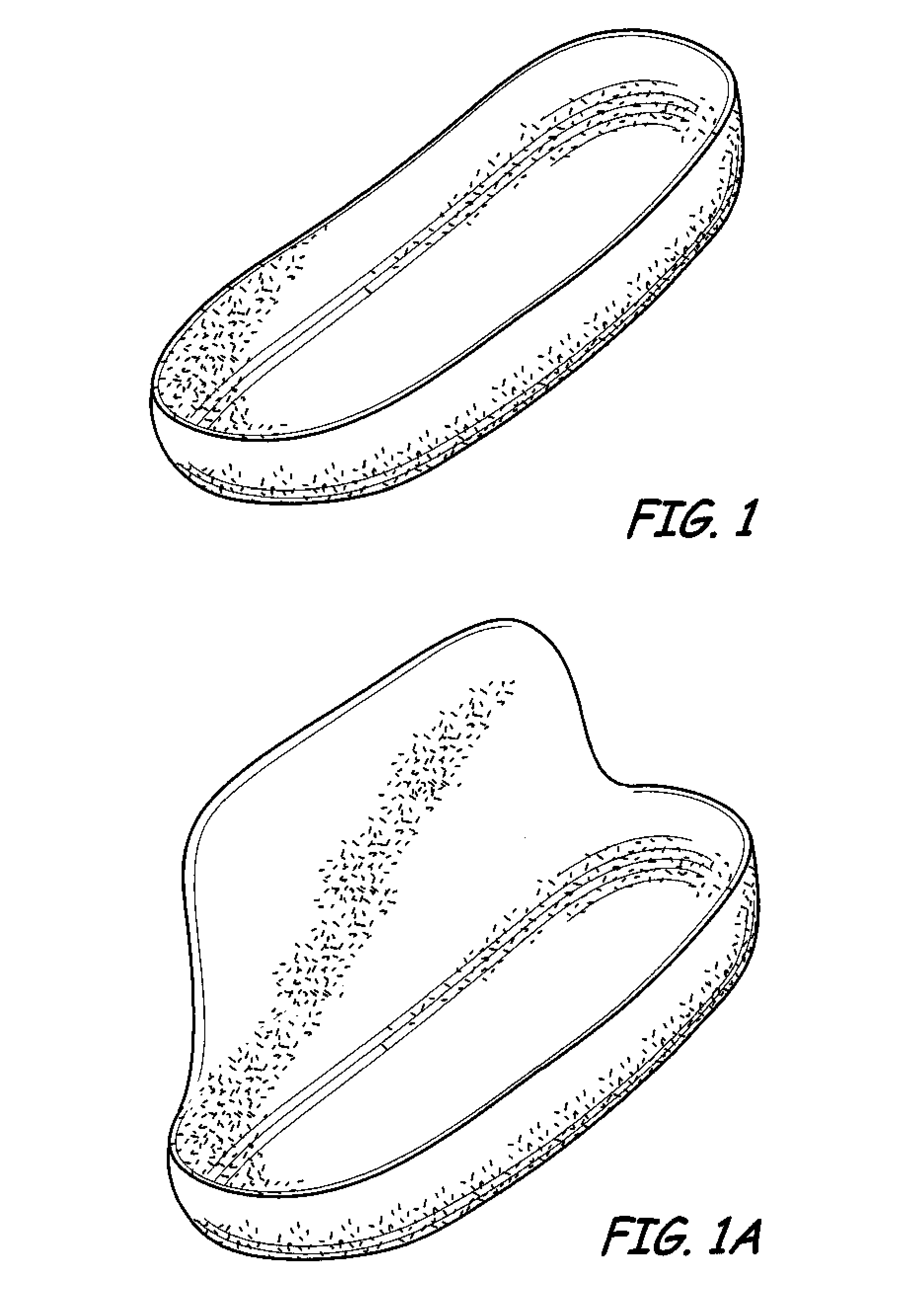

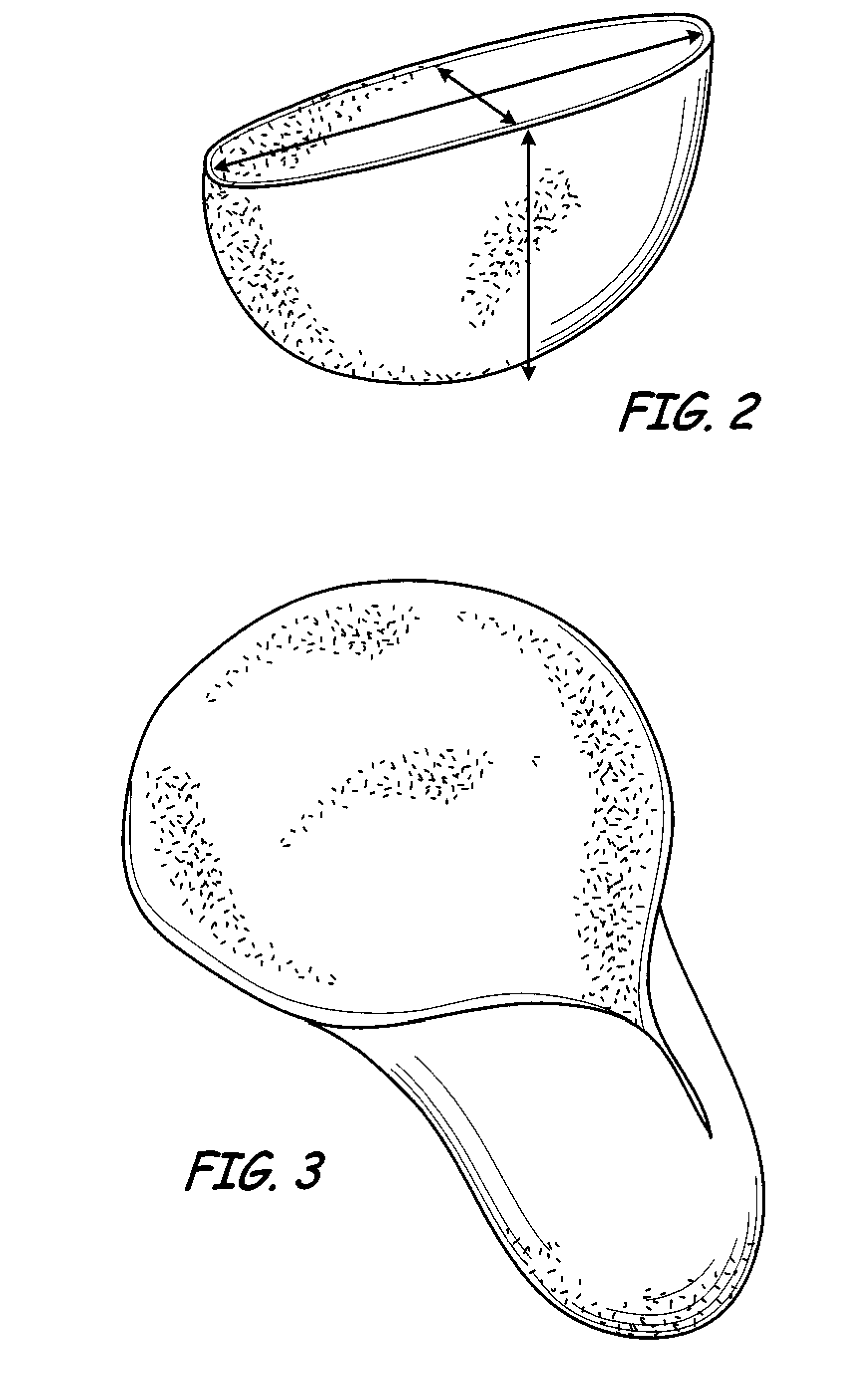

Soft Shaped Tortilla Procedure 1

[0133]1.) Ingredients were combined in mixer

2.) These were mixed 4-10 minutes on medium speed

3.) The dough was allowed to rest five minutes

4.) The dough was divided into 40-60 gram balls

5.) The dough balls were pressed in press comprising a preheated male and female mould with desired shape @400° F. (˜205° C.) for 1-3 seconds

6.) The shapes were removed from the moulds and baked in a tortilla oven @400° F. (˜205° C.) for 30-90 seconds

7.) The shapes were cooled five minutes on cooling rack

8.) The soft shaped tortillas were packaged

9.) Final tortilla moisture content was measured at 23-28%, Water Activity at <0.880

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com