Spray-free, high-weather-resistant and scratch-resistant PMMA material and preparation method thereof

A scratch-resistant, spray-free technology, which is applied in the field of polymer materials, can solve the problems of poor scratch resistance of PMMA alloy materials, weather resistance that cannot meet the use of exterior decorations, and weld lines that are prone to appear in spray-free materials, so as to achieve the goal of not sticking easily. The effect of adding other substances, solving the problem of difficult dispersion, and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

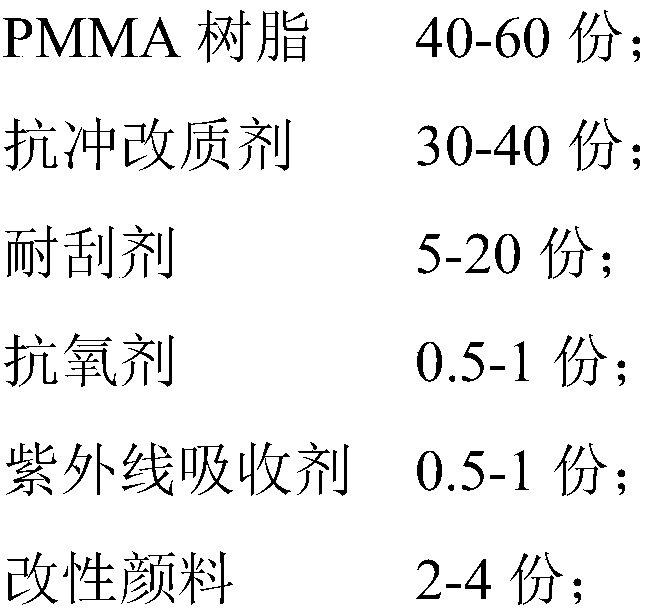

[0037] The formula of this embodiment is shown in Table 1:

[0038] Table 1

[0039]

[0040] The preparation method of PMMA material in this embodiment includes the following steps:

[0041] (1) Mix the above coupling agent with pigments 1, II, and III at high speed for 15 minutes, and bake at 105°C for 60 minutes for coupling treatment to obtain modified pigments.

[0042] (2) The polytetrafluoroethylene and silicone powder are mixed at a mass ratio of 96:4 for 5 minutes, and the mixture is placed in a twin-screw extruder, extruded and granulated to obtain a scratch-resistant agent. The twin screw speed is 230r / min, the extrusion temperature is 200℃-230℃, and the pelletizing speed is 400r / min.

[0043] (3) Mix the modified pigment prepared in step (1), the scratch-resistant agent prepared in step (2), and the remaining raw materials for 8 minutes, and place the mixture in a parallel twin-screw extruder for melt extrusion and granulation. It is necessary to avoid spraying high-gloss ...

Embodiment 2

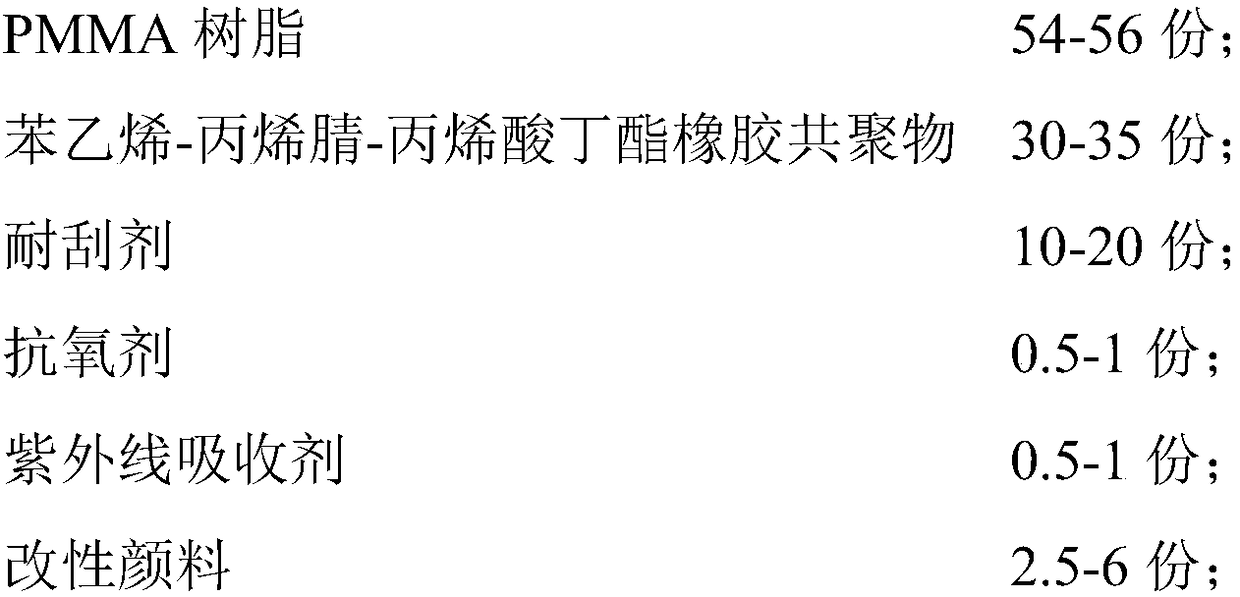

[0045] The formula of this embodiment is shown in Table 2:

[0046] Table 2

[0047]

[0048] The preparation method of the PMMA material of this embodiment is the same as that of the embodiment 1, and it is necessary to avoid spraying the high-gloss black PMMA material.

Embodiment 3

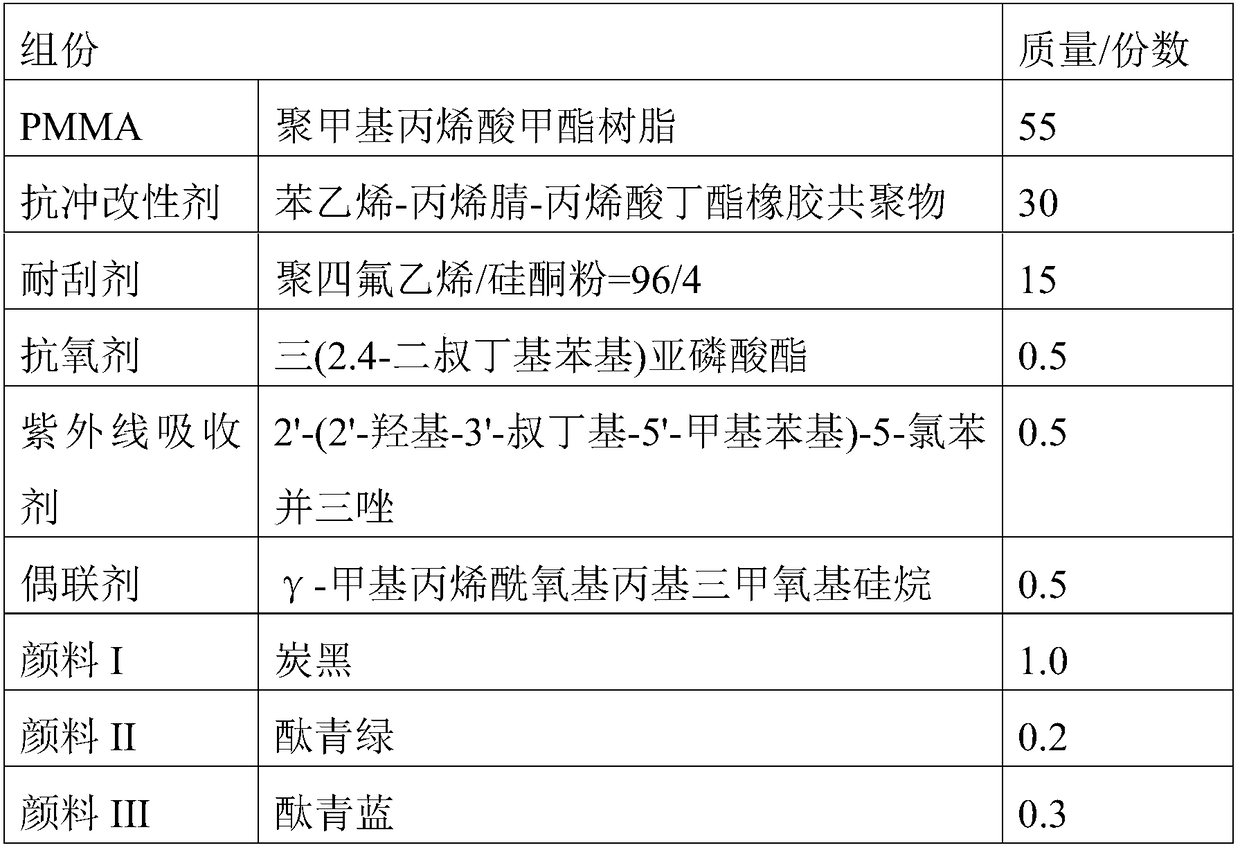

[0050] The formula of this embodiment is shown in Table 3:

[0051] table 3

[0052]

[0053] The preparation method of this embodiment is the same as that of embodiment 1, and it is necessary to avoid spraying the metal-like PMMA material. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com