High-density dark green glaze

A turquoise, dense technology, applied in the field of ceramic glaze processing, can solve the problems of reducing the service life of ceramic products, easy to penetrate into cracks and pinholes, easy to appear cracks and pinholes, etc., to improve the grade, avoid cracks and pinholes. The effect of holes, avoiding cracks and pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

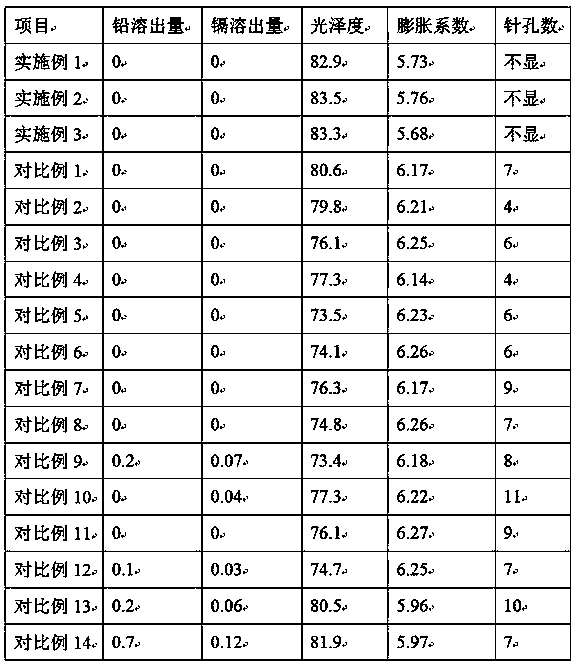

Examples

Embodiment 1

[0023] A high-density turquoise glaze, made of the following raw materials in parts by weight: silicon dioxide 39, talc powder 11, cerium oxide 7.6, lanthanum oxide 5.1, zirconium oxide 4.7, praseodymium oxide 4.4, cobalt oxide 4.2, titanium dioxide 3.8, Nano Zinc Oxide 3.2, Denatured Wollastonite 3.3, Chlorite 4.1, Salt 1.2.

[0024] For the denatured wollastonite, pulverize the wollastonite to 160 mesh, heat the wollastonite to 1200°C in vacuum, wait for the wollastonite to cool naturally to 200°C, add a mass percentage concentration twice the weight of the wollastonite to the wollastonite 5% ammonium acetate solution, keep warm for 40 minutes, then heat at 3°C / min to 800°C, keep warm for 30 minutes, and cool down to room temperature naturally, which can improve the stability and corrosion resistance of the glaze and avoid the growth of the glaze Bacteria and discoloration, keep the glaze smooth, get denatured wollastonite.

[0025] A preparation method of high-density turq...

Embodiment 2

[0037]A high-density turquoise glaze, made of the following raw materials in parts by weight: silicon dioxide 40, talcum powder 12, cerium oxide 8.0, lanthanum oxide 5.6, zirconia 5.1, praseodymium oxide 4.9, cobalt oxide 4.7, titanium dioxide 4.2, nano zinc oxide 3.8, denatured wollastonite 3.6, chlorite 4.4, table salt 1.5.

[0038] For the denatured wollastonite, pulverize the wollastonite to 180 mesh, heat the wollastonite to 1300°C in vacuum, wait for the wollastonite to cool naturally to 230°C, add a concentration of 2.5 times the weight of the wollastonite to the wollastonite It is 6% ammonium acetate solution, heat for 50 minutes, then heat to 850°C at a speed of 3.5°C / min, hold for 35 minutes, and cool to room temperature naturally, which can improve the stability and corrosion resistance of the glaze and avoid the growth of the glaze. Bacteria and discoloration, keep the glaze smooth, get denatured wollastonite.

[0039] A preparation method of high-density turquois...

Embodiment 3

[0051] A high-density turquoise glaze, made of the following raw materials in parts by weight: silicon dioxide 41, talc powder 13, cerium oxide 8.4, lanthanum oxide 6.2, zirconium oxide 5.5, praseodymium oxide 5.3, cobalt oxide 5.1, titanium dioxide 4.7, Nano Zinc Oxide 4.5, Denatured Wollastonite 3.9, Chlorite 4.7, Salt 1.8.

[0052] For the denatured wollastonite, pulverize the wollastonite to 200 mesh, heat the wollastonite to 1400°C in vacuum, wait for the wollastonite to cool naturally to 250°C, add a mass percentage concentration of 3 times the weight of the wollastonite to the wollastonite It is 7% ammonium acetate solution, keep warm for 60 minutes, then heat up to 900°C at a rate of 4°C / min, keep warm for 40 minutes, and cool down to room temperature naturally, which can improve the stability and corrosion resistance of the glaze and avoid the growth of the glaze Bacteria and discoloration, keep the glaze smooth, get denatured wollastonite.

[0053] A preparation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com