A kind of acrylic emulsion blending release force continuously adjustable pressure-sensitive adhesive formula and preparation method

An acrylic emulsion and peeling force technology, which is applied in the direction of ester copolymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of pressure-sensitive adhesive performance fluctuations, narrow peeling force range, and unfavorable large-scale production. , to achieve the effect of stable quality, avoiding performance fluctuations, and consistent degree of cross-linking reaction of the adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

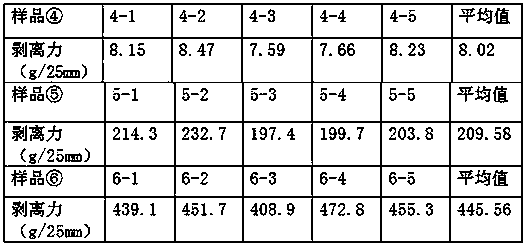

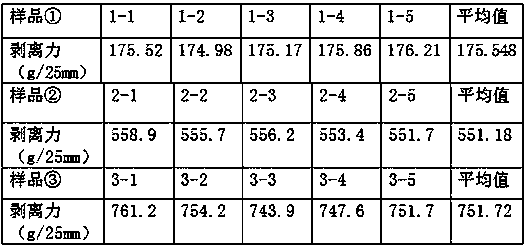

Examples

Embodiment 1

[0022] (1) Pre-emulsion preparation:

[0023] A: Add 500g of distilled water into the beaker, then add 11.5g of alkylphenol polyoxyethylene ether into it, and stir to dissolve it; then add 455.4g of butyl acrylate, 4.6g of acrylic acid, 2.3g of BYK-015, and stir well After mixing, pre-emulsify with an emulsifier for 10 minutes;

[0024] B: Add 500g of distilled water into the beaker, then add 13.5g of alkylphenol polyoxyethylene ether into it, and stir to dissolve; then add 486g of butyl acrylate, 54g of acrylic acid, 2.7g of BYK-015, stir well, mix Pre-emulsify for 10 minutes with an emulsifier;

[0025] (2) Reactor preheating:

[0026] A: Add 50g of distilled water into a clean 2L four-neck flask equipped with electric stirring, install the condenser tube and separatory funnel and seal the other nozzles, turn on nitrogen protection, then turn on electric stirring and constant temperature water bath for heating, Control the rotational speed evenly until the temperature of ...

Embodiment 2

[0035] (1) Pre-emulsion preparation:

[0036] A: Add 500g of distilled water into the beaker, then add 11.5g of sodium 12-alkylsulfonate into it, and stir to dissolve it; then add 455.4g of butyl acrylate, 4.6g of acrylic acid, 2.3g of BYK-012, and stir Evenly, after mixing, pre-emulsify with an emulsifier for 10 minutes;

[0037]B: Add 500g of distilled water into the beaker, then add 13.5g of sodium 12-alkylsulfonate into it, and stir to dissolve it; then add 486g of butyl acrylate, 27g of acrylic acid, 2.7g of BYK-012, stir well, After mixing, pre-emulsify with an emulsifier for 10 minutes.

[0038] (2) Reactor preheating:

[0039] A: Add 470g of distilled water to a clean 2L four-neck flask equipped with electric stirring, install the condenser tube and separatory funnel and seal the other nozzles, turn on nitrogen protection, then turn on electric stirring and constant temperature water bath for heating, Control the rotational speed evenly until the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com