Bottom structure of extrusion forming metal bottle and optimization method

A bottom structure and extrusion molding technology, applied in the field of packaging, can solve the problems of unfavorable axial bearing pressure and compressive strength, reduce the volume of the container, increase the amount of materials, etc., to increase the axial bearing pressure and pressure resistance of the bottom of the bottle The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

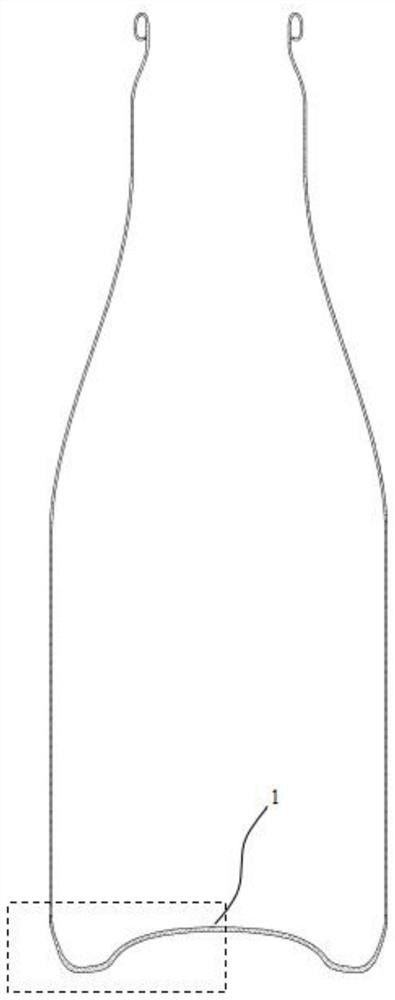

[0042] see image 3 , Figure 4 , Figure 5 , this embodiment provides a bottom structure of an extruded metal bottle, including a bottom body 1, the bottom body 1 is a center-symmetric rotary body, the rotary body is a semi-closed cylindrical structure, and the semi-closed tube The structure includes a side wall section ab, a transition arc section bc, a slope structure section cd, a ground contact section df, and an arched structure section eh arranged sequentially from top to bottom, and the ground contact section df contains the ground contact point e, there is an overlapping portion between the ground contact portion segment df and the arched structure segment eh, and each segment of the semi-closed cylindrical structure is a smooth transition of a curved surface; the generatrix of the side wall segment ab is a vertical line, so The generatrix of the transition arc section bc is a circular arc, the generatrix of the slope structure section cd is an inclined straight lin...

Embodiment 2

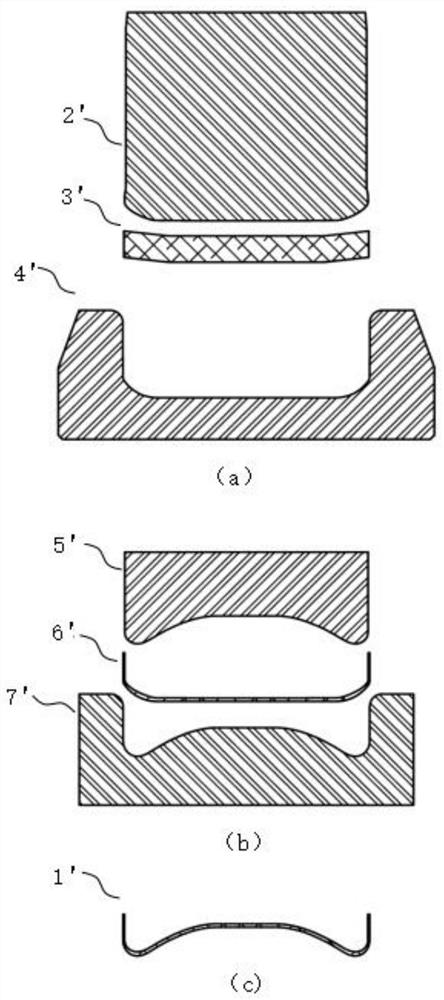

[0051] This embodiment provides a method for optimizing the bottom structure of the extruded metal bottle described in Embodiment 1, and its specific steps are as follows:

[0052] (1) Carry out simulation calculations on the bottom structure of existing products, and use the calculated results of axial bearing pressure and compressive strength as reference standards;

[0053] (2) Design an initial model, and calculate the axial bearing pressure and compressive strength;

[0054] (3) Take the key geometric parameters of the bottom structure as variables, set the amount of material constant, the volume of the bottle body, the diameter of the bottle body, and the height of the bottle body as constraints, and change the value of the geometric variables to obtain a new Bottom structure model, and simulated calculations to obtain the axial bearing pressure and compressive strength of the new bottom structure;

[0055] (4) Compare the obtained axial bearing pressure and compressive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com