Method for selectively synthesizing sapo-15 and sapo-34 molecular sieves

A technology of SAPO-15 and SAPO-34, which is applied in the field of preparation of inorganic porous materials, can solve the problems of long crystallization time, cumbersome process of active aluminum source, and large amount of template agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

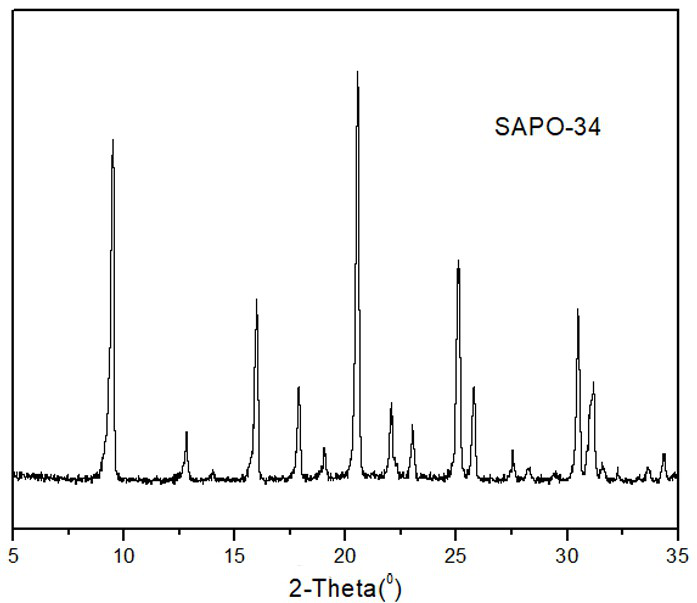

[0040] The synthesis of embodiment 1 pure phase SAPO-34 molecular sieve

[0041] First, 9.2 ml of phosphoric acid was dissolved in 28.0 g of deionized water, then 9.2 g of pseudoboehmite, 4.1 g of gaseous silicon dioxide, 11.6 ml of morpholine and 39 ml of water were added in sequence, and stirred evenly. The molar ratio of each species is SiO 2 :Al 2 o 3 :R:P 2 o 5 :H 2 O=0.76:1.0:1.48:0.87:41.3, the above reaction sol was sealed in a 150 ml stainless steel autoclave with a polytetrafluoroethylene liner, crystallized at 200°C for 48 hours, and quickly dropped to At room temperature, the solid product was separated by filtration, washed with deionized water to neutrality, and dried overnight at 100°C to obtain the product, which was tested by X-ray diffraction (XRD). Diffraction (XRD) pattern see attached figure 1 .

Embodiment 2

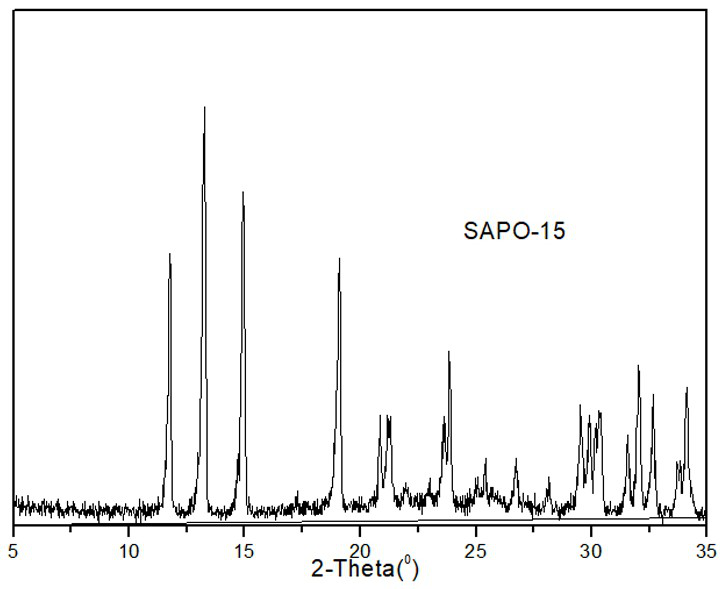

[0042] The synthesis of embodiment 2 pure phase SAPO-15 molecular sieves

[0043] First, dissolve 9.2 ml of phosphoric acid in 28.0 g of deionized water, then add 9.2 g of pseudoboehmite, 4.1 g of gaseous silicon dioxide, 11.6 ml of morpholine and 15 ml of water in sequence, stir evenly, and then add 16.6 g of ammonium chloride and 24ml water. The molar ratio of each species is SiO 2 :Al 2 o 3 : R: P 2 o 5 :H 2 O: NH 4 + =0.76:1.0:1.48:0.87:41.3:3.3, seal the above reaction sol in a 150 ml stainless steel autoclave with polytetrafluoroethylene lining, crystallize at 200°C for 48 hours, drop rapidly after taking out the autoclave to room temperature, filter to separate the solid product, wash with deionized water to neutrality, and dry overnight at 100°C to obtain the product, which is the crystal phase structure of pure phase SAPO-15 molecular sieve by X-ray diffraction (XRD), and the X-ray of the sample The ray diffraction (XRD) pattern is shown in the appendix fi...

Embodiment 3

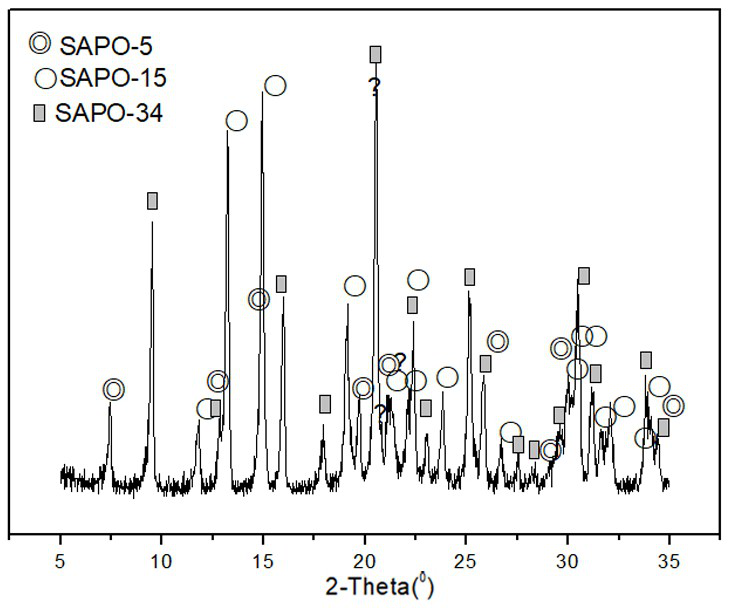

[0044] Example 3 Synthesis of SAPO-5, SAPO-15 and SAPO-34 mixed crystal molecular sieves

[0045] First, dissolve 4.6 ml of phosphoric acid in 14.0 g of deionized water, then add 4.6 g of pseudoboehmite, 2.1 g of gaseous silicon dioxide, 5.8 ml of morpholine and 7.5 ml of water in sequence, stir evenly, and then add 0.91 g ammonium chloride and 12ml water. The molar ratio of each species is SiO 2 :Al 2 o 3 :R:P 2 o 5 : H 2 O: NH 4 + =0.76:1.0:1.48:0.87:41.3:0.18, the above reaction sol was sealed in a 100 ml stainless steel autoclave lined with polytetrafluoroethylene, and crystallized at 200°C for 48 hours. to room temperature, filter to separate the solid product, wash with deionized water until neutral, and dry overnight at 100°C to obtain the product, which is SAPO-5, SAPO-15 and SAPO-34 mixed crystal molecular sieves by X-ray diffraction (XRD) The crystal phase structure of the sample, the X-ray diffraction (XRD) figure of the sample is shown in the attached im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com