Bag type environment-friendly auxiliary special for PVC (polyvinyl chloride) floor substrate production and preparation method thereof

A stone-plastic floor, environmentally friendly technology, applied in the field of organic-inorganic composite materials, to achieve the effects of increasing compatibility, improving affinity, and improving extrusion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

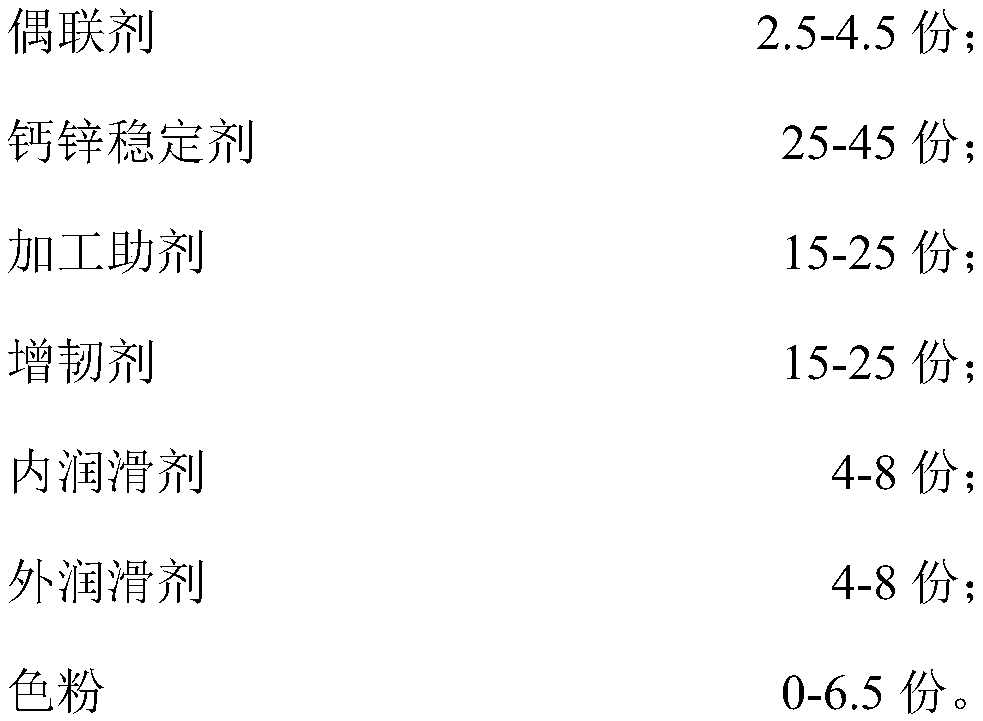

[0028] The composition of a bag-type environmental protection additive specially used in the production of PVC stone-plastic floor base material in the present embodiment is:

[0029] 4 parts of aluminate coupling agent, 40 parts of calcium zinc stabilizer, 21 parts of ACR processing aid, 21 parts of MBS toughening agent, 7 parts of monoglyceride, 6 parts of polyethylene wax, and 1 part of carbon black.

[0030] The specific preparation method is:

[0031] (1) Pre-mix the calcium-zinc stabilizer and the aluminate coupling agent at a mass ratio of 10:1 at 100°C for 10-20 minutes, remove moisture, and obtain a coupling agent / calcium-zinc stabilizer composite;

[0032] (2) Mix and dry the above compound with ACR processing aid, MBS toughening agent, monoglyceride, polyethylene wax, and carbon black at 80°C according to a preset ratio;

[0033] (3) sieve the mixture in step (2), and remove the sieve residue with a diameter greater than 60 mesh;

[0034] (4) The powdery mixed pro...

Embodiment 2

[0036] The composition of a bag-type environmental protection additive specially used in the production of PVC stone-plastic floor base material in the present embodiment is:

[0037] 3.5 parts of aluminate coupling agent, 35 parts of calcium zinc stabilizer, 25 parts of ACR processing aid, 22 parts of MBS toughening agent, 7 parts of stearic acid, 7.5 parts of Fischer-Tropsch wax.

[0038] The specific preparation method is:

[0039] (1) Pre-mix the calcium-zinc stabilizer and the aluminate coupling agent at a mass ratio of 10:1 at 100°C for 10-20 minutes, remove moisture, and obtain a coupling agent / calcium-zinc stabilizer composite;

[0040] (2) Mix and dry the above compound with ACR processing aid, MBS toughening agent, stearic acid and Fischer-Tropsch wax at 80°C according to a preset ratio;

[0041] (3) sieve the mixture in step (2), and remove the sieve residue with a diameter greater than 60 mesh;

[0042] (4) The powdery mixed product in step (3) is weighed, measur...

Embodiment 3

[0044] The composition of a bag-type environmental protection additive specially used in the production of PVC stone-plastic floor base material in the present embodiment is:

[0045] 2.5 parts of aluminate coupling agent, 25 parts of calcium zinc stabilizer, 25 parts of ACR processing aid, 25 parts of MBS toughening agent, 8 parts of monoglyceride, 8 parts of polyethylene wax, and 6.5 parts of carbon black.

[0046] The specific preparation method is:

[0047] (1) Pre-mix the calcium-zinc stabilizer and the aluminate coupling agent at a mass ratio of 10:1 at 80°C for 10-20 minutes, remove moisture, and obtain a coupling agent / calcium-zinc stabilizer complex;

[0048] (2) Mix and dry the above compound with ACR processing aid, MBS toughening agent, monoglyceride, polyethylene wax, and carbon black at 100°C according to a preset ratio;

[0049] (3) sieve the mixture in step (2), and remove the sieve residue with a diameter greater than 60 mesh;

[0050] (4) The powdery mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com