MEMS (Micro Electro Mechanical System) piezoresistive type absolute pressure sensor based on SOI (Silicon on Insulator) silicon chip

An absolute pressure, piezoresistive technology, applied in piezoelectric devices/electrostrictive devices, processes for producing decorative surface effects, piezoelectric/electrostrictive/magnetostrictive devices, etc., which can solve the overload resistance capability Limited, low overload resistance, etc., to achieve the effects of good performance, high yield, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below through specific embodiments and accompanying drawings.

[0033] In the manufacturing method of the MEMS piezoresistive pressure sensor of this embodiment, piezoresistors are manufactured on the four side walls of the shallow rhombic groove by ion implantation after etching the shallow rhombic groove on the surface of the silicon wafer. The steps of the method include:

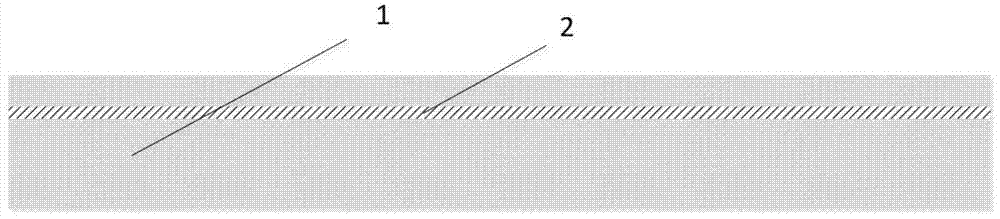

[0034] 1) Choose (100) SOI (silicon on insulator) silicon wafer as the chip substrate;

[0035] 2) Fabricate a P-type heavily doped contact region by ion implantation on the front side of the substrate, and activate the implanted impurities by high-temperature thermal annealing after completion;

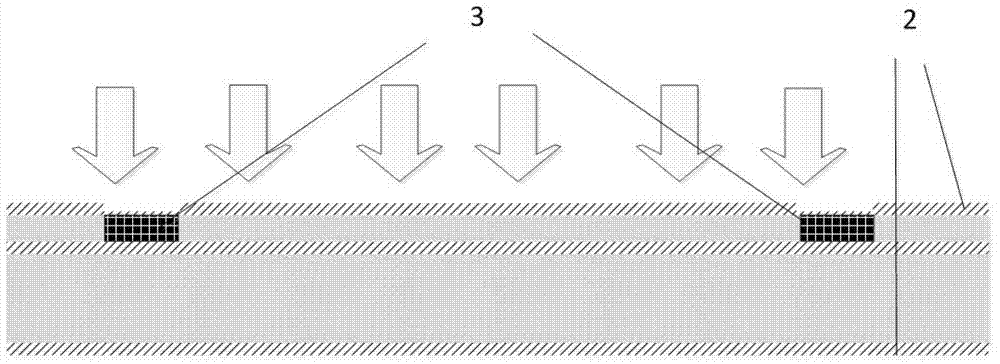

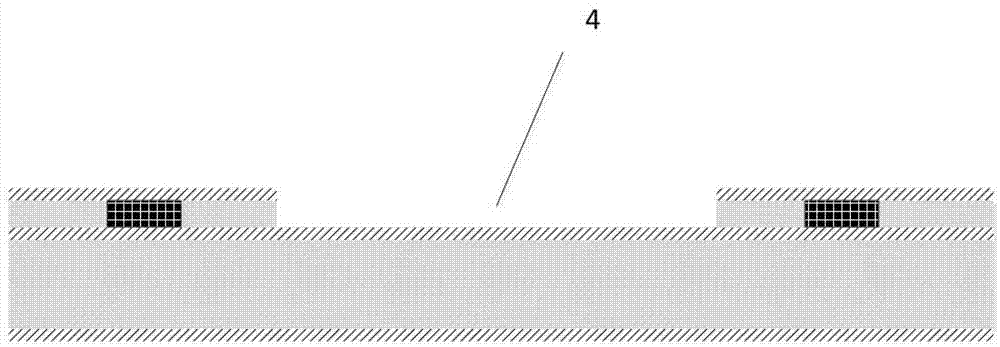

[0036] 3) Define the shape of the front shallow groove by photolithography, and make the shallow groove by reactive ion etching; after completion, high temperature thermal annealing is used to activate the implanted impurities;

[0037] 4) Fabricate piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com