Coated heat-sensitive paper and processing technology thereof

A thermal paper, lamination technology, used in papermaking, paper coatings, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Preparation of lubricating layer:

[0051] Mix and stir the modified water-based silicone resin and water evenly to obtain a lubricating layer slurry (in terms of mass ratio, modified water-based silicone resin: water = 3:7), and then use a gravure coater to coat one side of the film The lubricating layer slurry is dried at 120°C, and the coating amount is controlled at 0.1g / m 2 ;

[0052] Preparation of thermosensitive dye layer:

[0053] The binder and sensitizer in the heat-sensitive dye layer are dissolved in a mixed solvent of toluene and methyl ethyl ketone, and at the same time, the method of heating to 65°C is used to assist the dissolution. After the dissolution is complete, the heat-sensitive dye and filler are added after cooling, and the high-speed Disperse evenly to obtain the heat-sensitive fuel layer slurry; in which, in terms of mass ratio, toluene: methyl ethyl ketone: solid material (each material in the heat-sensitive dye layer) = 4:3:3, and then us...

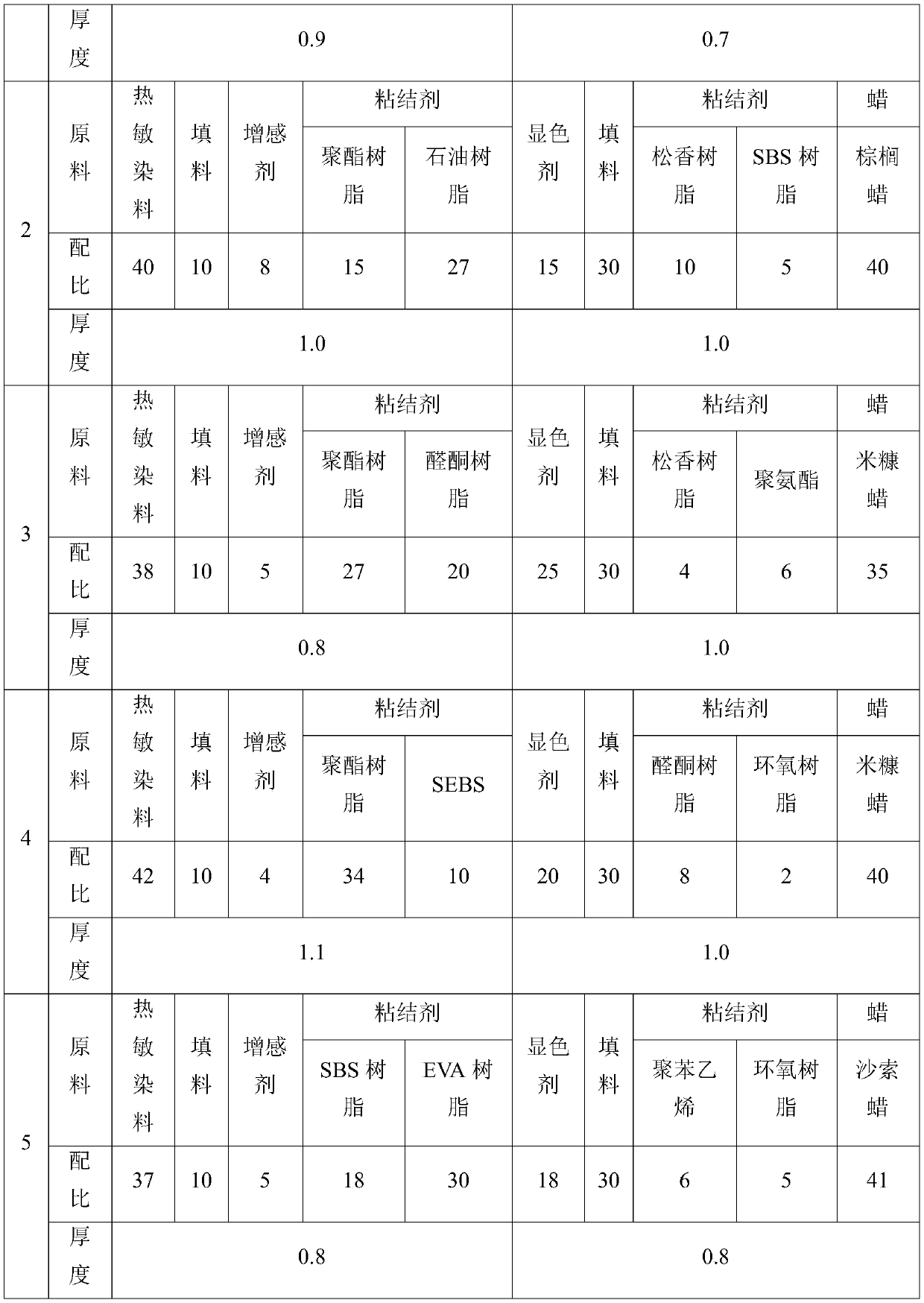

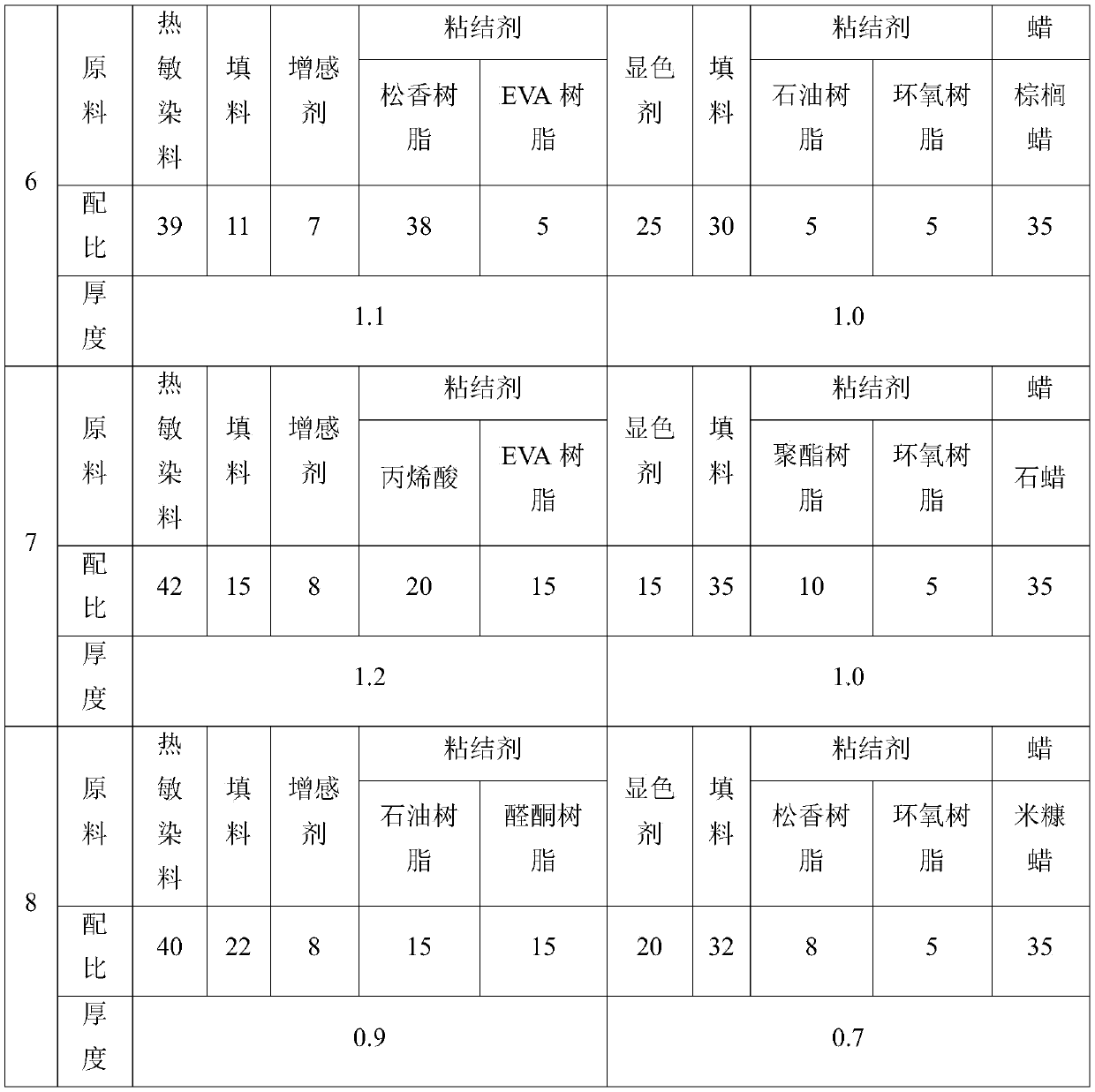

Embodiment 1~8

[0057] The specific material proportioning situation in each embodiment is shown in the table below.

[0058]

[0059]

[0060]

[0061] In the research process of the present invention, in order to obtain the appropriate proportion of the materials used in the heat-sensitive developer layer and the heat-sensitive dye layer, some control experiments were carried out by adjusting the amount of each material, and some typical control experiments are now selected as comparative examples. ,details as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com