Method for producing non-oriented electrical steel in endless rolling mode through sheet billets

A technology of oriented electrical steel and endless rolling, which is applied in the field of iron and steel, can solve problems such as head and tail temperature, plate shape and thickness fluctuations, many head and tail cuts, and long time, so as to achieve good product surface quality and improve finished product quality. The effect of high rate and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

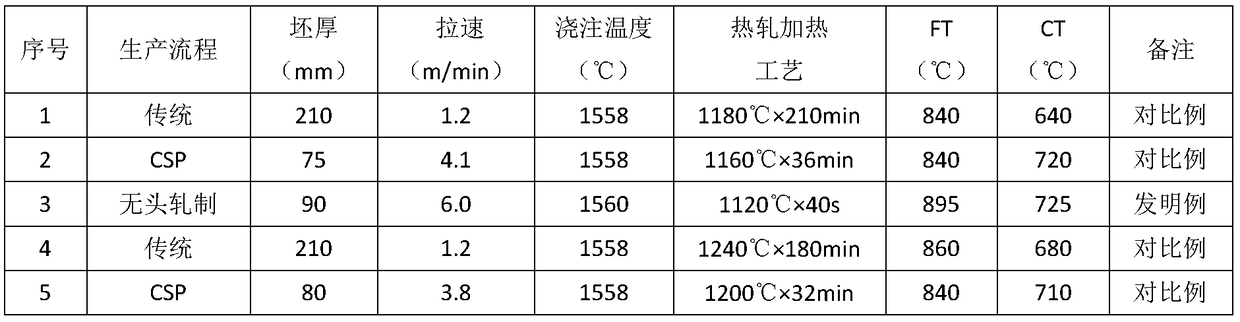

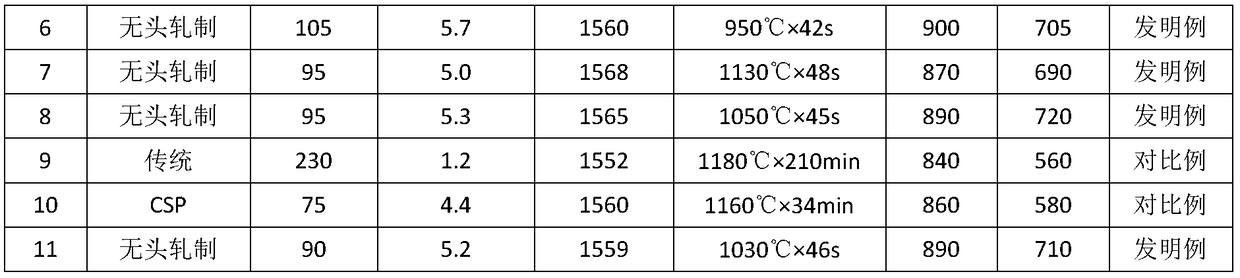

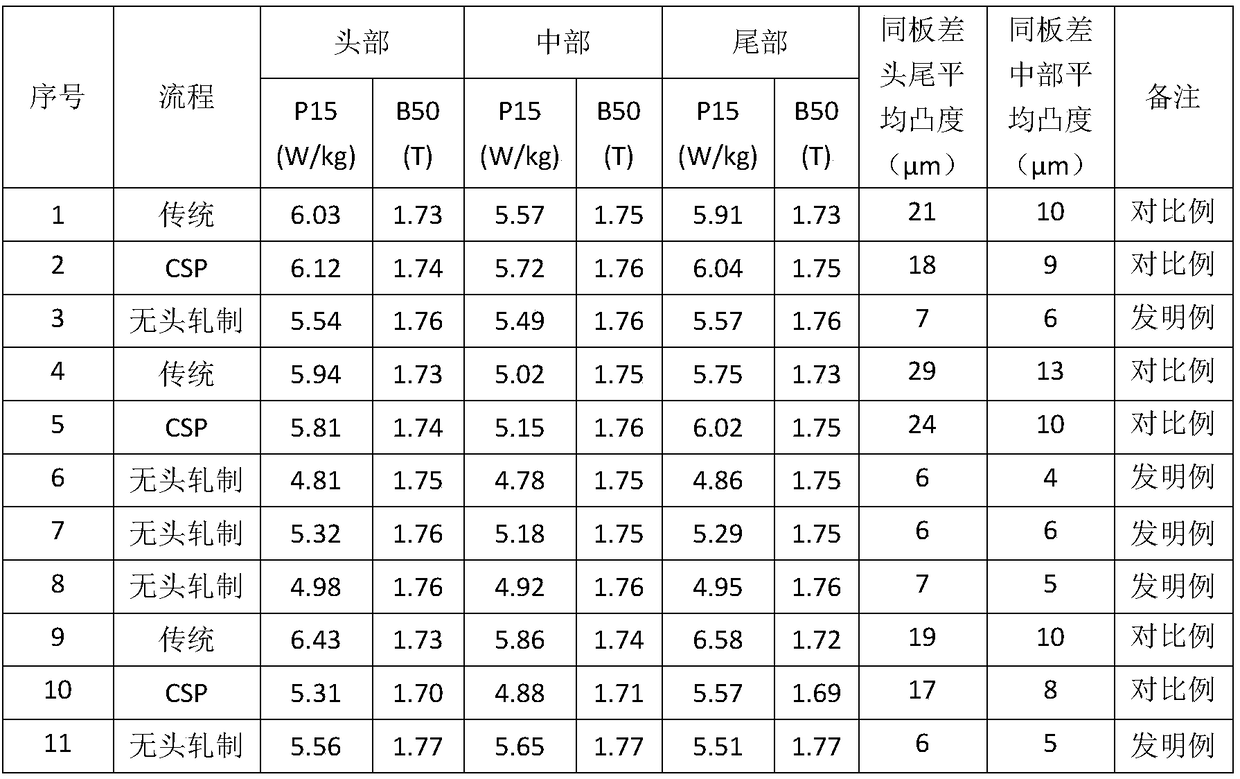

[0032] The smelting of non-oriented electrical steel is carried out according to the pretreatment of molten iron, converter steelmaking, and vacuum treatment. The smelting composition is shown in Table 1. The continuous casting and hot-rolling production processes are shown in Table 2. The hot-rolled strips are pickled, cold-rolled into 0.50mm cold-rolled strips, and subjected to dry gas annealing at 850°C for 60s. The magnetic properties and the same-plate difference were measured, and the properties are shown in Table 3.

[0033] Table 1 Steelmaking composition %

[0034] serial number

C

Si

mn

S

als

N

Production Process

1

0.0027

0.53

0.41

0.0045

0.0040

0.0021

Tradition

2

0.0027

0.53

0.41

0.0045

0.0040

0.0021

CSP

3

0.0027

0.53

0.41

0.0045

0.0040

0.0021

endless rolling

4

0.0035

0.82

0.24

0.0031

0.0029

0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com