Acoustic reinforcing material block, application of acoustic reinforcing material block, micro loudspeaker and application of micro loudspeaker

A micro-speaker and reinforcement material technology, applied in the field of speakers, can solve the problems of limited product ID design, increased mold cost, loss of natural feeling, etc., to achieve improved drop resistance reliability, reduced fragmentation, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

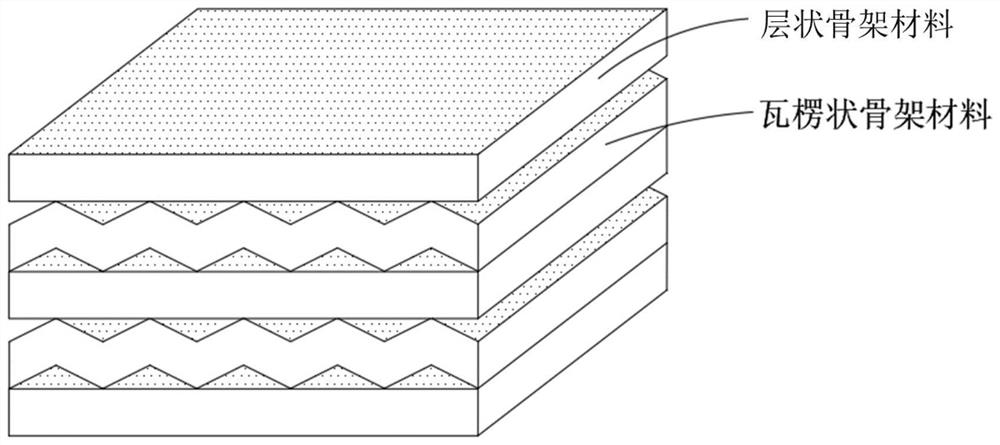

Embodiment 1

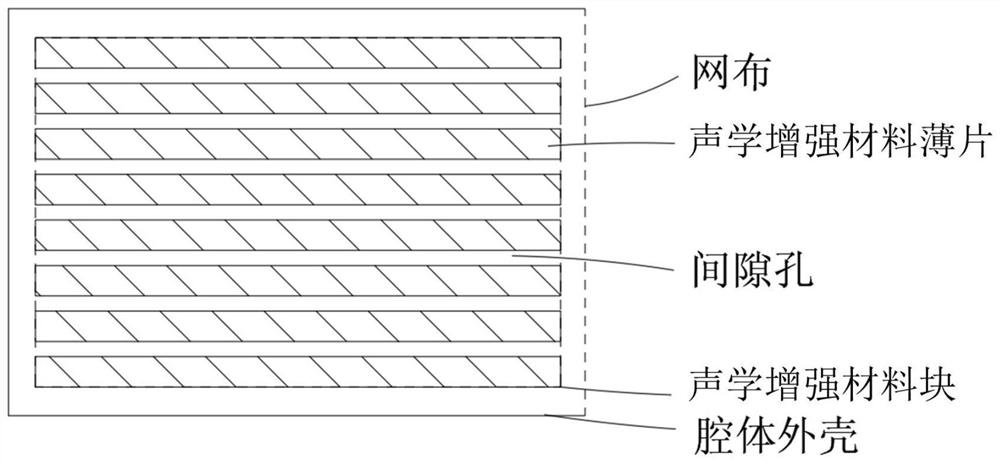

[0062] This embodiment provides an acoustic enhancement material block, based on the total weight of the acoustic enhancement material block as 100%, the material includes 6.4% polyacrylate suspension, 0.1% CMC, 12.6% skeleton material, and the balance is porous material . Wherein, the porous material used is MFI structural molecular sieve, and its Si / M mass ratio is 350, wherein M is aluminum; the skeleton material used is formed by alternately stacking layered fiber paper, and the fiber paper is made of chopped alkali-free glass fibers passing through It is obtained by wet process, and it is surface-treated with silane coupling agent KH550. The gram weight per unit area of the fiber paper is 25g / m2 2 , the fiber diameter is 7 μm.

[0063] In the process of preparing the above-mentioned acoustic reinforcing material block, the fiber paper is first cut into a size and shape suitable for the speaker cavity to be filled, and then the polyacrylate suspension, CMC and MFI mole...

Embodiment 2

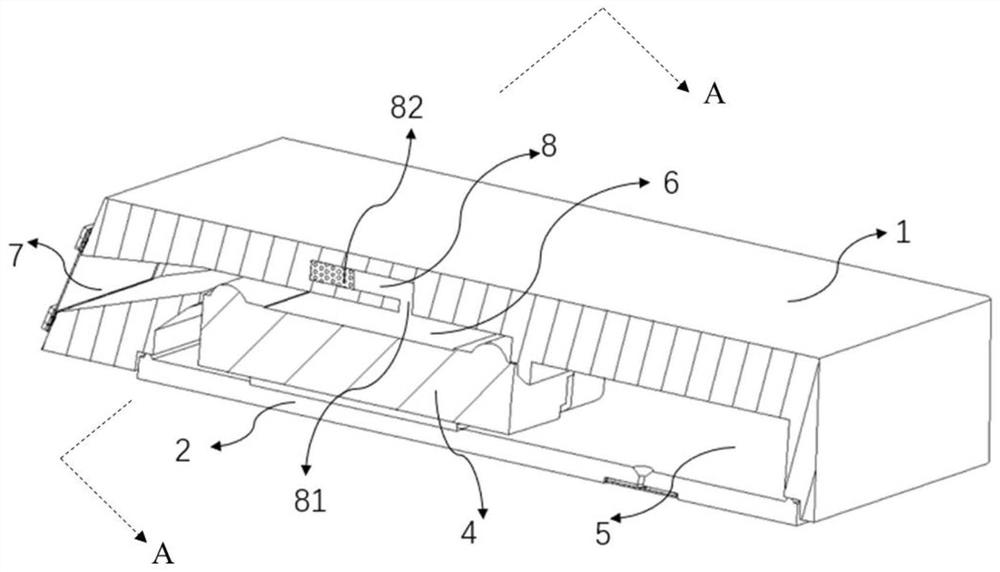

[0066] This embodiment provides a miniature speaker, Figure 3-Figure 4 It is a schematic diagram of the structure of the micro-speaker. like Figure 3-Figure 4 As shown, the micro-speaker includes an upper shell 1 , a lower shell 2 and a speaker unit 4 .

[0067] The upper shell 1 and the lower shell 2 are glued together to form a sealed inner cavity. In appearance, the upper shell 1 and the lower shell 2 together form a rectangular shell of the micro-speaker.

[0068] Wherein, the lower shell 2 is the bottom shell of the micro-speaker.

[0069] The upper shell 1 is the top shell and the side shell of the micro speaker, and the top and the side surface of the upper shell 1 are integrally formed. One side surface of the upper shell 1 is provided with a sound outlet 7 . The inner top surface of the upper shell 1 is provided with three vertically downward limiting protrusions 61, the limiting protrusions 61 are located on the opposite side and the adjacent side of the sound...

Embodiment 3

[0075] This embodiment provides a miniature speaker, Figure 5-Figure 8 It is a schematic diagram of the structure of the micro-speaker. like Figure 5-Figure 8 As shown, the micro-speaker includes an upper shell 1 , a lower shell 2 and a speaker unit 4 .

[0076] like Image 6 As shown, the upper shell 1 and the lower shell 2 are bonded to form a sealed inner cavity. In terms of appearance, the upper shell 1 and the lower shell 2 together form a rectangular shell of the micro speaker. The upper shell 1 is the top shell, the side shell and the inner shell of the micro-speaker, and the lower shell 2 is the bottom shell of the micro-speaker.

[0077] The upper casing 1 of this embodiment is further provided with a first blocking wall 91 , a second blocking wall 92 and an annular boss 93 on the basis of the upper casing 1 in the second embodiment. Specifically, the upper casing 1 of this embodiment includes a first casing 11 and a second casing 31 . The first shell 11 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com