Shearing machining process for aging precipitation strengthened copper alloy material

A technology of precipitation strengthening and processing technology, applied in the field of material processing, can solve the problems of difficult operation, fluctuation of material performance, large energy consumption, etc., to achieve the effect of improving production efficiency, improving performance indicators, and shortening the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

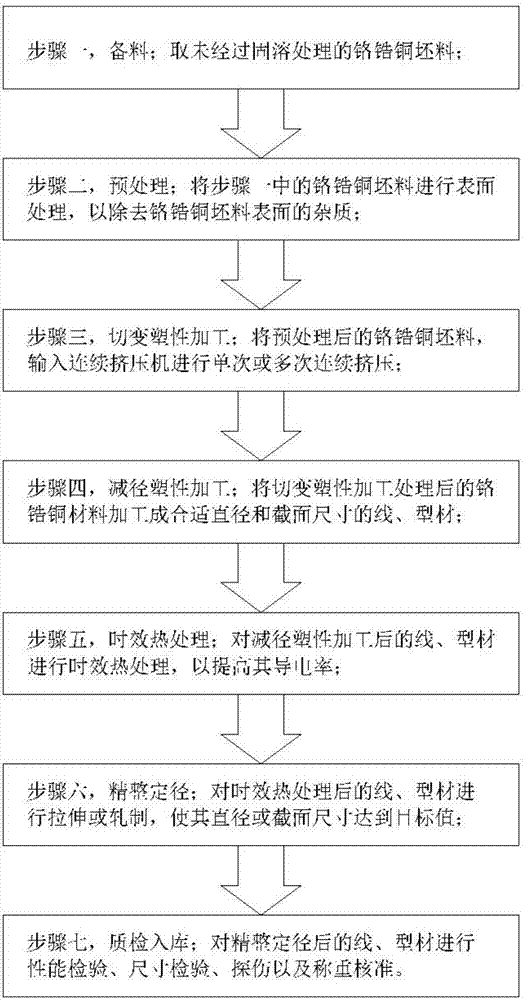

[0039] figure 1 The process flow chart of the shear processing process of the aging precipitation strengthening type copper alloy wire and profile material provided by the first embodiment of the present invention.

[0040] Such as figure 1 As shown, the present embodiment provides a shear processing technology for aging precipitation strengthening type copper alloy wire and type material, including the following steps:

[0041] Step 1, preparing materials; taking the chromium-zirconium-copper blank that has not been solid-solution treated;

[0042] The chromium-zirconium-copper billet is a straight bar or disc with a diameter of 8-40mm, and the chromium-zirconium-copper billet can be in a casting state, a rolling state, an extruding state or a forging state.

[0043] Step 2, pretreatment; the chromium-zirconium-copper blank in step 1 is subjected to surface treatment to remove impurities on the surface of the chromium-zirconium-copper blank;

[0044] The surface treatment ...

no. 2 example

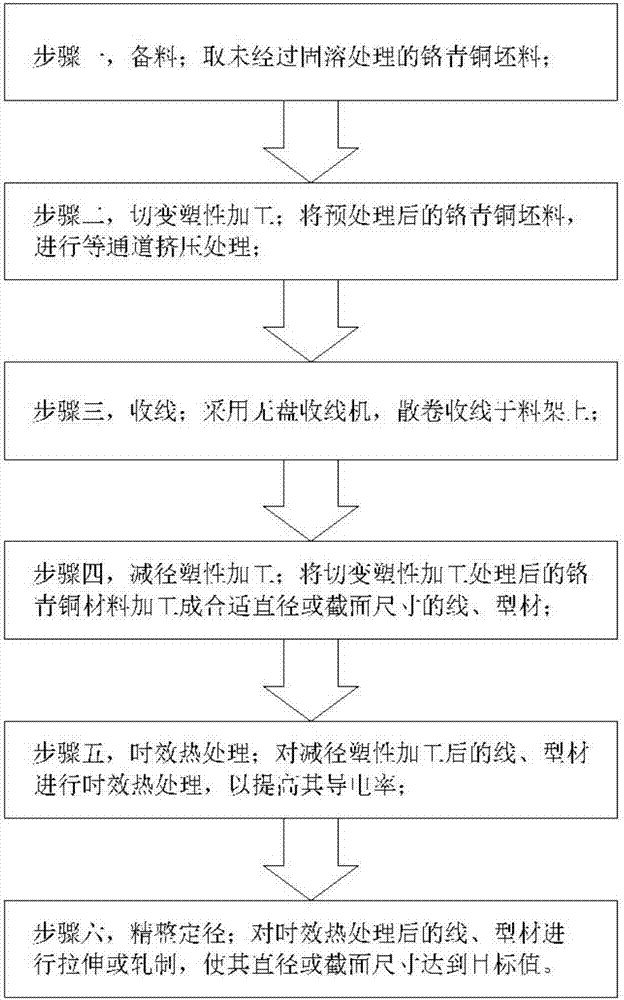

[0063] figure 2 The process flow chart of the shear processing process of the aging precipitation strengthening type copper alloy wire and type material provided for the second embodiment of the present invention.

[0064] Such as figure 2 As shown, the present embodiment provides a shear processing technology for aging precipitation strengthening type copper alloy wire and type material, including the following steps:

[0065] Step 1: Prepare materials; take a chromium bronze blank that has not been solution-treated; the chromium bronze blank is a straight bar or a disc with a diameter of 8-40mm, and the conventional size includes but is not limited to: 8mm, 20mm, 25mm, and 30mm. The chrome bronze billet can be cast, rolled, extruded or forged.

[0066] Step 2, shear plastic processing; the pretreated chromium bronze billet is subjected to equal-channel extrusion treatment; equal-channel extrusion, as a method of strong plastic deformation, can refine the grain size of th...

no. 3 example

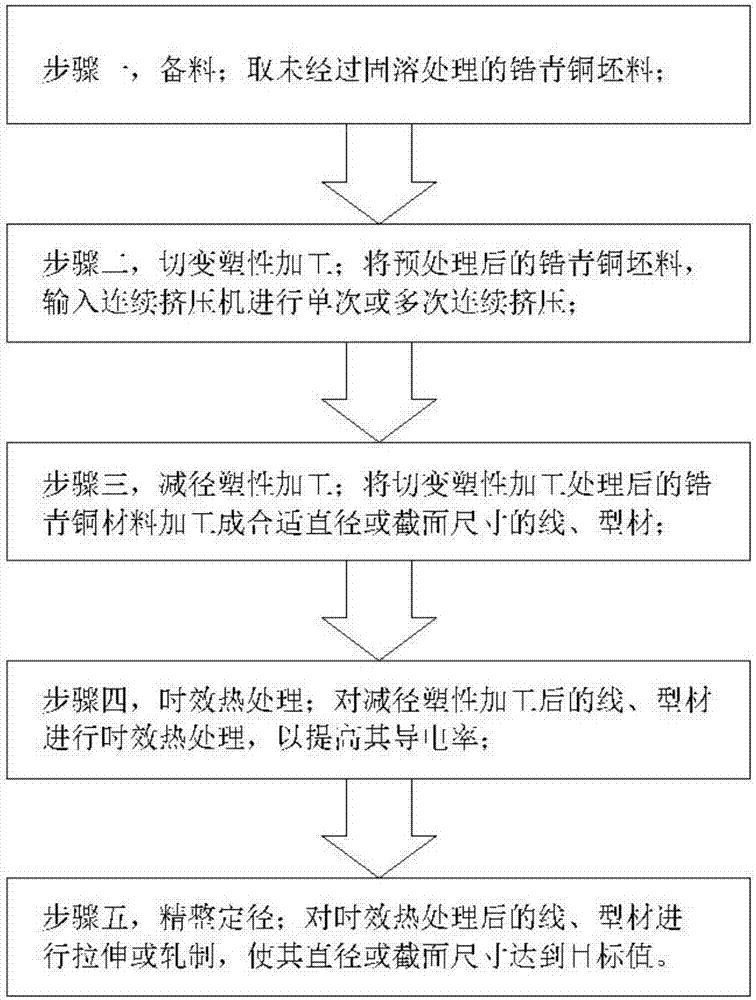

[0078] image 3 The third embodiment of the present invention provides a process flow chart of the shear processing process of the aging precipitation strengthening type copper alloy wire and profile material.

[0079] Such as image 3 As shown, the present embodiment provides a shear processing technology for aging precipitation strengthening type copper alloy wire and type material, including the following steps:

[0080] Step 1, prepare materials; get the zirconium bronze blank that has not been solid solution treated;

[0081] The zirconium bronze blank is a straight bar or a disc with a diameter of 8-40 mm, and the zirconium bronze blank can be in a cast state, a rolled state, an extruded state or a forged state.

[0082] Step 2, shear plastic processing; input the pretreated zirconium bronze billet into a continuous extrusion machine for single or multiple continuous extrusion;

[0083] The shear plastic working of described step 2 comprises the following steps succes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com