Quenched and tempered steel sheet and manufacturing method thereof

A technology of quenched and tempered steel plate and manufacturing method, applied in the field of 80kg ultra-thick quenched and tempered steel plate and its manufacturing field, can solve problems such as uneven strength and toughness, and achieve the effect of excellent weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

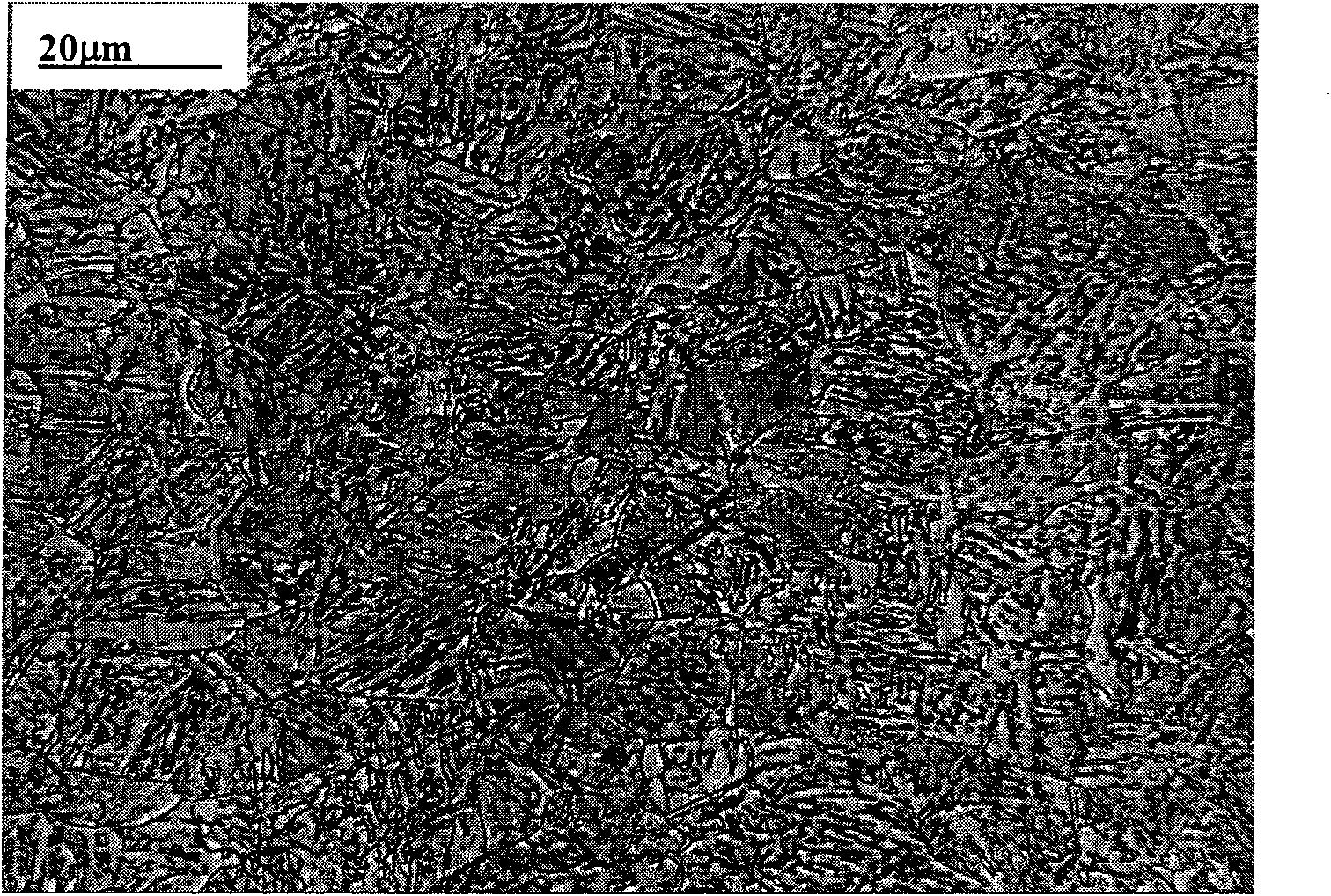

Image

Examples

Embodiment Construction

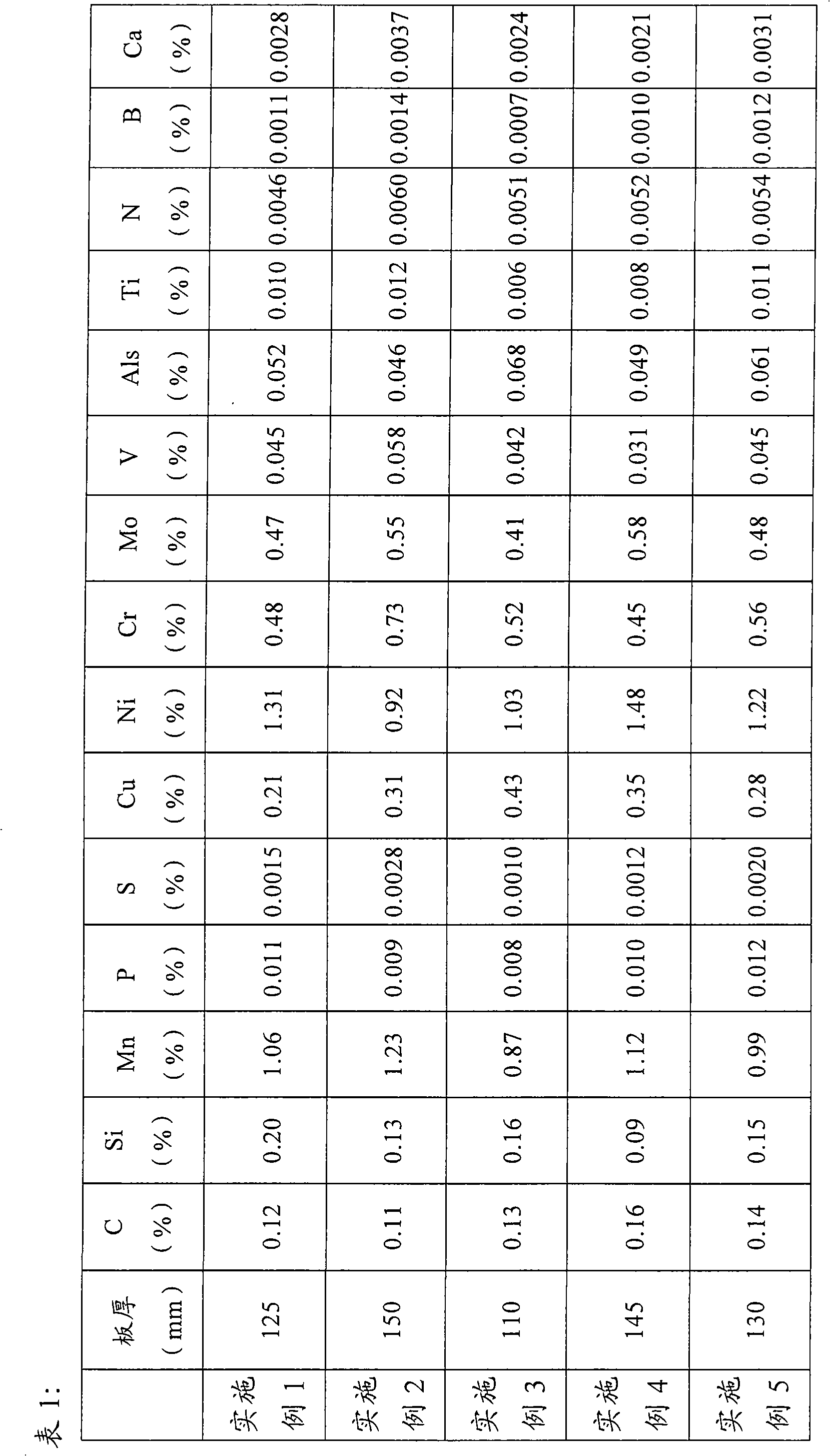

[0057] Table 1 has shown according to the different embodiments of 80 kilograms super-thick quenched and tempered steel plates of the present invention;

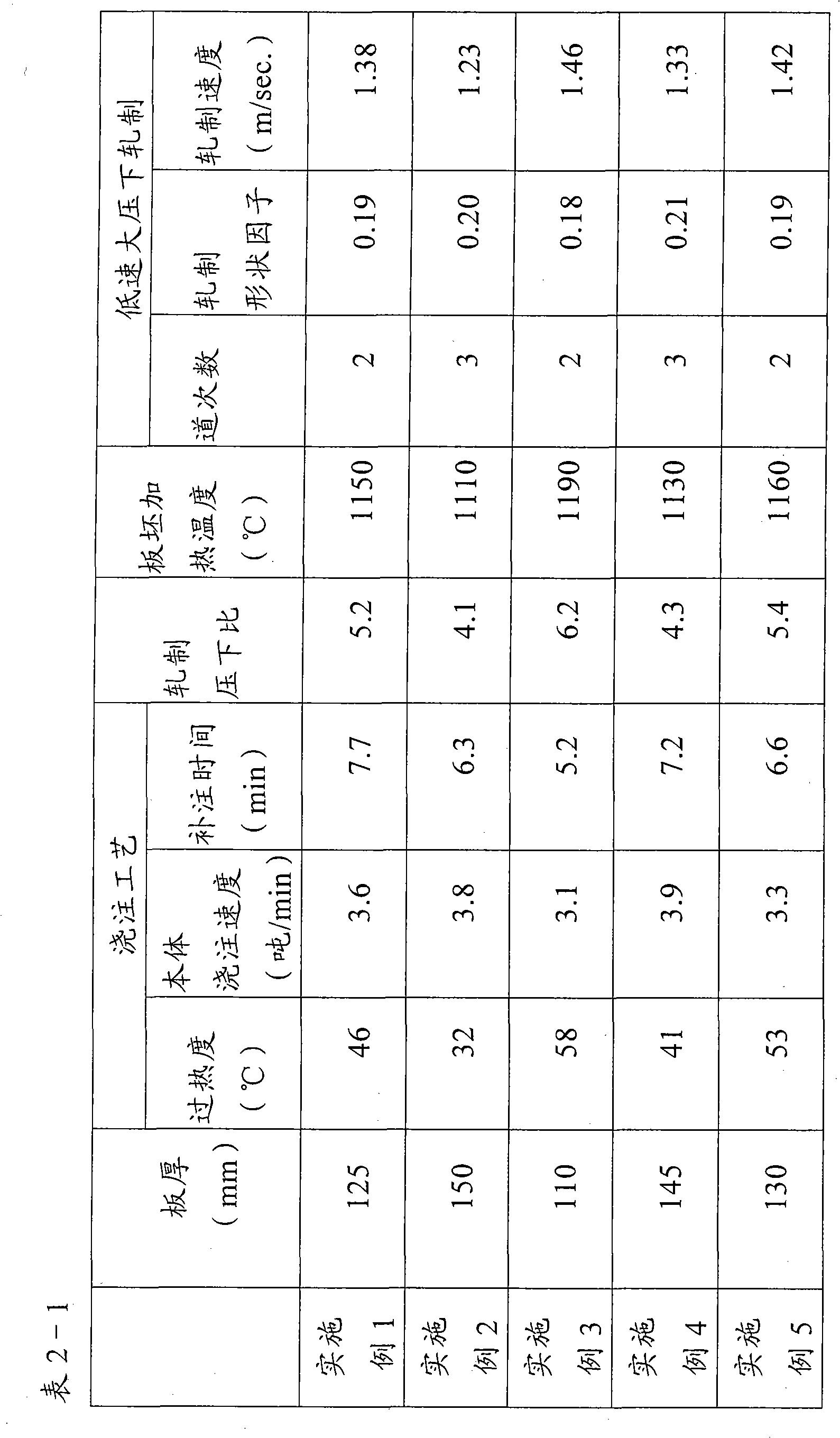

[0058] Table 2 has shown the different embodiments according to the manufacturing method of 80 kilograms super-thick quenched and tempered steel plates of the present invention;

[0059] Table 3 shows the properties of the 80 kg class ultra-thick quenched and tempered steel plate according to the present invention.

[0060]According to the present invention, the mass percentages of chemical components in different embodiments shown in Table 1 can be used for the 80 kg class ultra-thick quenched and tempered steel plate.

[0061] The manufacture method of 80 kilograms class ultra-thick quenched and tempered steel plate of the present invention is as follows:

[0062] Die casting is adopted, the ladle pouring superheat ΔT is controlled at 30°C to 60°C, the body pouring speed is controlled at 3.0t / min to 4.0t / min, and the rise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com