A preparation method of nano-carbon reinforced titanium matrix composite with strong plasticity matching

A technology of titanium-based composite materials and nano-carbon, which is applied in the field of metal-based composite materials, can solve the problems of difficulty in obtaining uniform and thick metal coatings, industrial production restrictions, and pollution of plating metal waste liquid, so as to reduce high-temperature interface reactions, Improve plasticity, particle reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

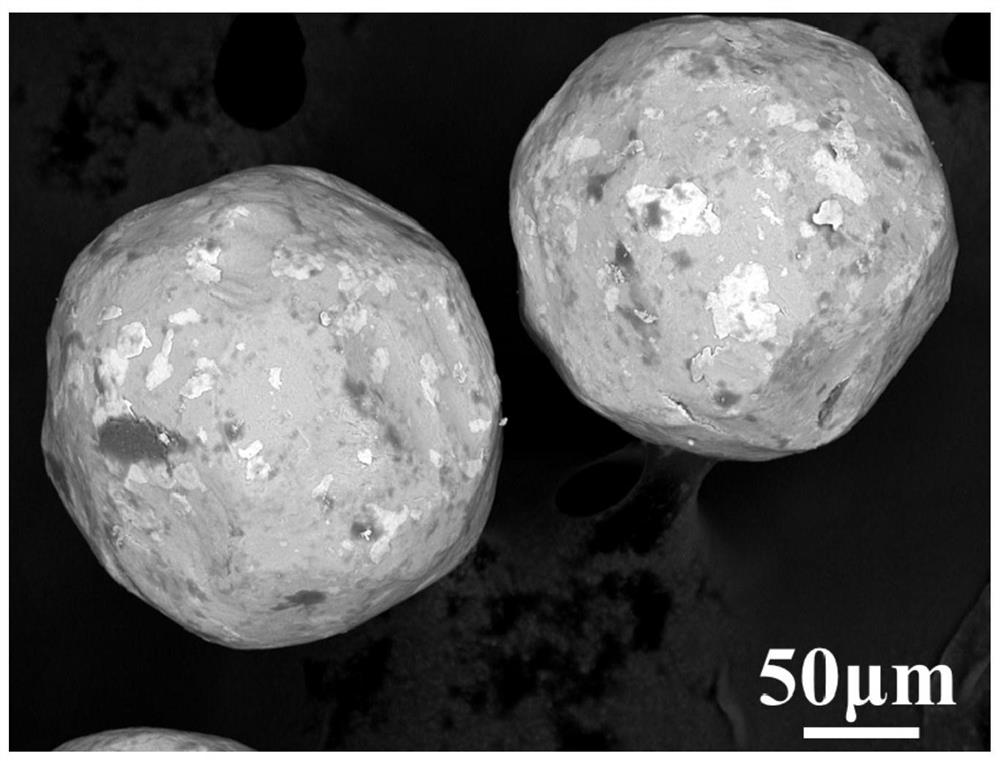

[0031]Step 1. Modification of titanium-based powder: 195 g of pure titanium powder with a particle size of 70 μm to 150 μm and 5 g of Cu powder with an average particle size of 48 μm are subjected to high-energy ball milling to obtain metal-modified titanium-based powder; the high-energy ball mill The rotating speed adopted is 500r / min, the time is 3h, and the ball-to-material ratio is 3;

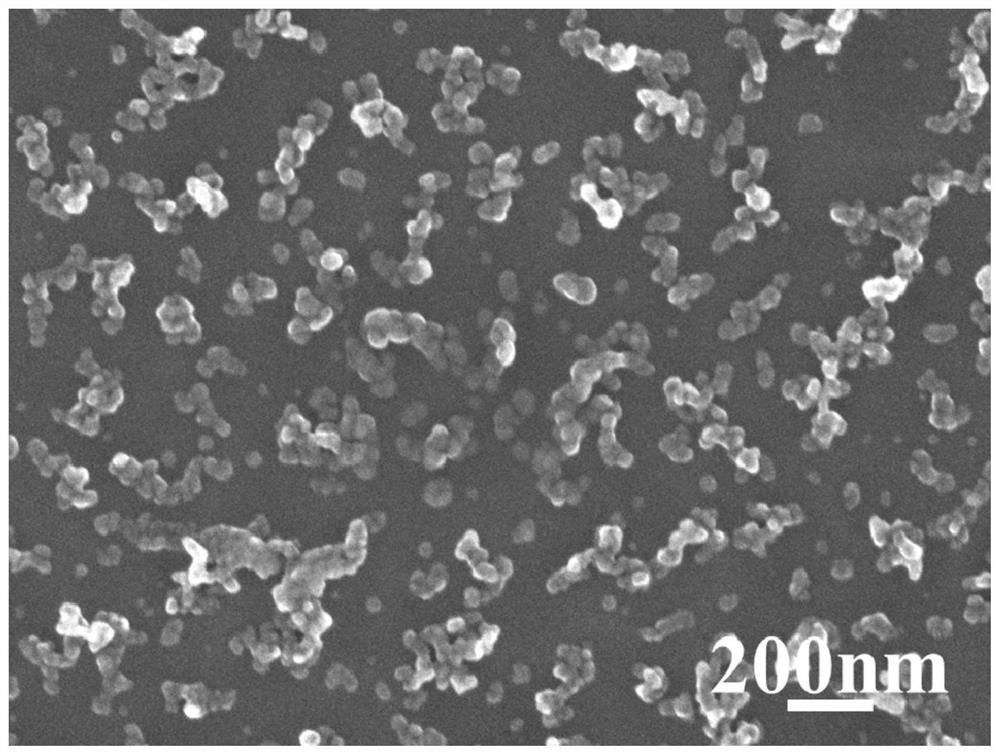

[0032] Step 2. Preparation of nano-carbon-metal modified titanium-based powder: The metal-modified titanium-based powder obtained in step 1 is mixed with 0.6g graphene nanosheets to obtain nano-carbon-metal modified titanium-based powder. ; The rotating speed adopted in the low-energy powder mixing treatment is 150r / min, the time is 3h, and the ball-to-material ratio is 3;

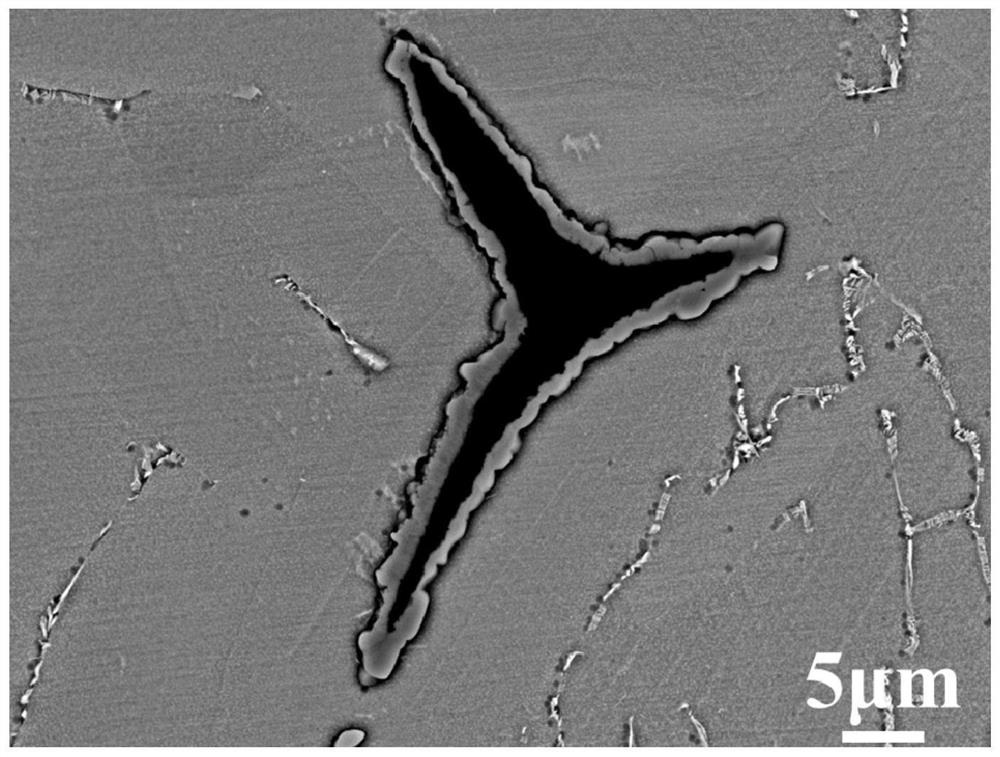

[0033] Step 3, preparation of nano-carbon-reinforced titanium-based composite material: the nano-carbon-metal modified titanium-based powder obtained in step 2 is ...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] Step 1. Modification of titanium-based powder: 198g of TC4 titanium alloy powder with a particle size of 53 μm to 150 μm and 2 g of Ni powder with a particle size of 75 μm are subjected to high-energy ball milling to obtain a metal-modified titanium-based powder; the high-energy ball milling treatment The rotating speed adopted is 200r / min, the time is 5h, and the ball-to-material ratio is 3;

[0047] Step 2. Preparation of nano-carbon-metal modified titanium-based powder: the metal-modified titanium-based powder obtained in step 1 and 0.6 g of graphene oxide are mixed with low-energy powder to obtain nano-carbon-metal modified titanium-based powder; The rotating speed adopted in the low-energy powder mixing treatment is 50r / min, the time is 10h, and the ball-to-material ratio is 4;

[0048] Step 3, preparation of nano-carbon-reinforced titanium-based composite material: the nano-carbon-metal modified titanium-base...

Embodiment 3

[0056] This embodiment includes the following steps:

[0057] Step 1. Modification of titanium-based powder: 198g of TC4 titanium alloy powder with a particle size of 53 μm to 150 μm and 2 g of Cr powder with a particle size of 100 μm are subjected to high-energy ball milling to obtain metal-modified titanium-based powder; the high-energy ball mill treatment The rotating speed adopted is 300r / min, the time is 2h, and the ball-to-material ratio is 4;

[0058] Step 2. Preparation of nano-carbon-metal modified titanium-based powder: The metal-modified titanium-based powder obtained in step 1 is mixed with 0.6g graphene nanosheets to obtain nano-carbon-metal modified titanium-based powder. ; The rotating speed adopted in the low-energy powder mixing treatment is 100r / min, the time is 8h, and the ball-to-material ratio is 2;

[0059] Step 3, preparation of nano-carbon-reinforced titanium-based composite material: the nano-carbon-metal modified titanium-based powder obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com