Hot-rolling seamless steel pipe applicable to high temperature of 580-620 DEG C and high pressure of 24-30MPa and production method thereof

A seamless steel pipe, 30mpa technology, applied in heat treatment furnaces, temperature control, heat treatment equipment and other directions, can solve problems such as high price, inability to guarantee rolling ratio, and restricting the development of the power industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

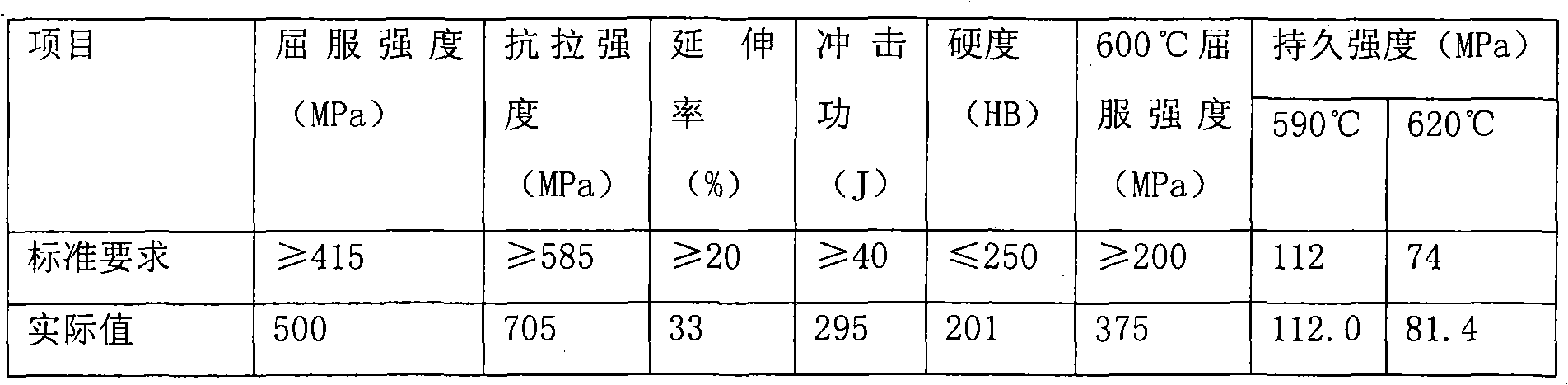

[0034]The chemical composition of the hot-rolled seamless steel pipe used at a high temperature of 580-620 °C and a high pressure of 24-30 MPa is (wt%) C: 0.10%, Si: 0.33%, Mn: 0.45%, P: 0.009%, S: 0.003 %, Ni: 0.08%, Cr: 8.28%, Mo: 0.91%, Cu: 0.08%, Al: 0.011%, V: 0.20, Nb: 0.08%, Ti: <0.010%, N: 0.0471%, and the balance is Fe.

Embodiment 2

[0036] Ratio of electric furnace ingredients: molten iron: 45t; pipe head: 45t; bottom ash: 2 tons. Electric furnace tapping requires C≤0.06%, P≤0.005%. Before tapping, add 2 bags of S removal agent, use 0.5 tons of silicon-calcium-barium deoxidizer for deoxidation, add 1 ton of molybdenum ferromolybdenum, and 0.1 tons of lime. The tapping temperature is guaranteed to be 1680-1690°C.

[0037] Ladle refining: add micro-carbon Cr iron in batches, adjust Mo, V, Nb, Si and other alloying elements to pass after reaching the target value.

[0038] VD: VD high vacuum time must be guaranteed to be ≥ 10 minutes, then feed Ca-Si wire and CrN cored wire, and then change to blow N 2 About 20min.

[0039] Die Casting: Cast the molten steel after VD, protect the ingot mold by argon blowing before casting, and heat the ingot mold at the same time, and strictly control the casting temperature to ensure the quality of the mold casting billet. When the mold temperature drops to 500℃, the mol...

Embodiment 3

[0041] The steel pipe is rolled by a three-roll high-precision pipe rolling unit PQF. After the tube billet is cut to length, it enters the ring furnace and is heated to 1150°C. If the temperature is too high or too low, the plasticity of the tube billet will deteriorate, which will easily cause surface quality defects of the steel pipe. In the deformation process such as sizing, according to the characteristics of high alloy content such as Cr and Mo, through experimental research, the initial rolling temperature is controlled to be less than 1300 °C, and the final rolling temperature is greater than 800 °C. The final outer diameter deviation is controlled at about +0.91%, and the wall thickness deviation is controlled at about +10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com