High-concentration emulsion treatment method and treatment system

A treatment method and wastewater treatment system technology, applied in the field of high-concentration emulsion treatment methods and treatment systems, can solve the problems of increasing the difficulty of screening agents, fixed methods are difficult to adapt to waste emulsions, and large amounts of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

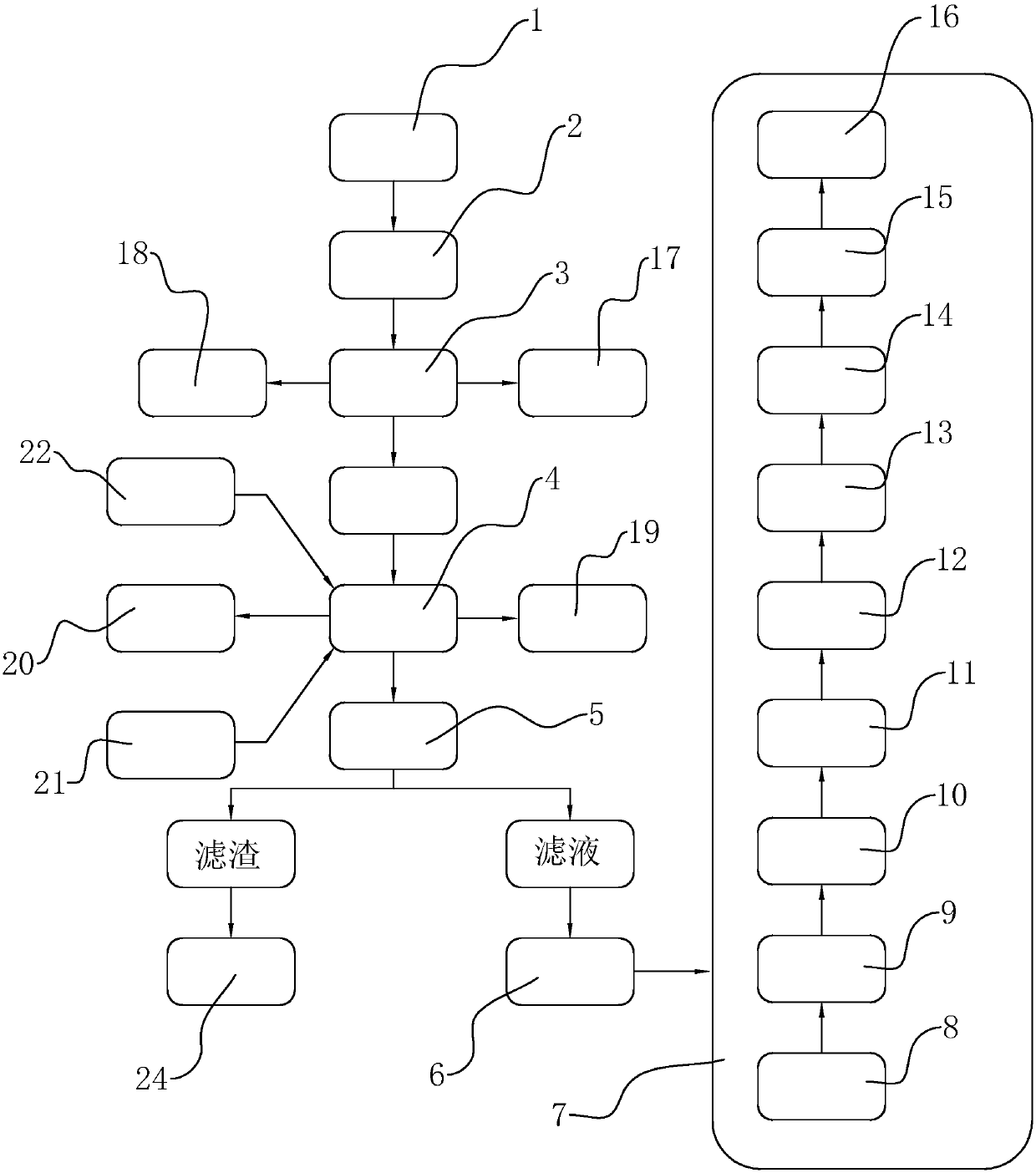

[0040] Embodiment 1: a kind of processing method of high-concentration emulsion, in conjunction with figure 1 and figure 2 As shown, the following steps are included: S1, collection and treatment: separately collect the waste emulsion received from the outside into the waste emulsion storage tank 1, after static precipitation, collect the slick oil on the upper layer of the waste emulsion storage tank 1, and waste The waste emulsion in the lower layer of the emulsion storage tank 1 is passed into the acid precipitation reaction tank 2 .

[0041] S2. Acidification: adding sulfuric acid with a pH of 2-2.5 into the acid analysis reaction tank 2 for acidification treatment.

[0042] S3. Primary coagulation and sedimentation: add demulsifier to the acidified waste emulsion, heat it at the same time, and then pass it into the grease trap 3 for static sedimentation, discharge the upper layer of slick oil into the oil recovery device, and the middle layer of waste emulsion Pass int...

Embodiment 2

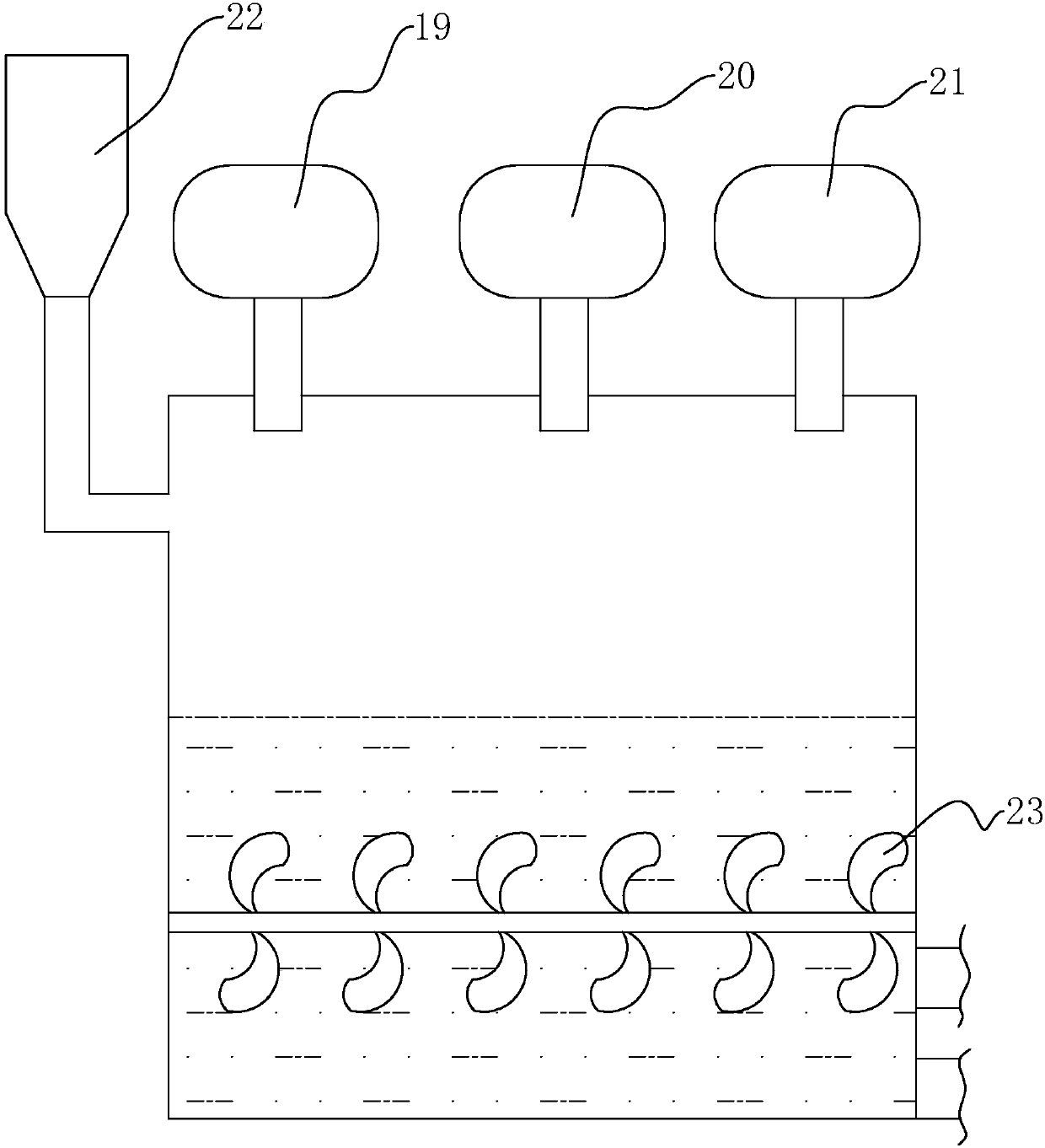

[0048] Embodiment 2: a kind of emulsion wastewater treatment system, combined with figure 1 and figure 2 As shown, it includes sequentially connecting the waste emulsion storage tank 1 for collecting the waste emulsion, the acid out reaction tank 2 for acidification and demulsification, and the oil separator for adjusting the flow of the waste emulsion and removing its separated liquid and suspended matter Pool 3, Fenton reaction tank 4 for oxidation treatment of waste emulsion, filter press 5 for sludge pressing treatment, evaporation tank 6 for evaporating and fractionating filter press 5 press-filtered liquid, and The water outlet of the evaporation tank 6 is connected with a biochemical device 7 for biochemically treating the waste emulsion.

[0049]Wherein, the biochemical device 7 includes a filtrate collection tank 8 which is connected in sequence for homogenizing the waste emulsion after physical and chemical treatment, and an anaerobic pool 9 for anaerobic organisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com