Lithium-rich manganese-based cathode material with coated and compounded surface and preparation method of lithium-rich manganese-based cathode material

A lithium-rich manganese-based, cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems affecting the energy density, power performance and service life of lithium-ion batteries, capacity decay of lithium-ion cathode materials, and shortened battery life. mileage and service life and other issues, to achieve the effect of improving regional restrictions, improving applications, and solving poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

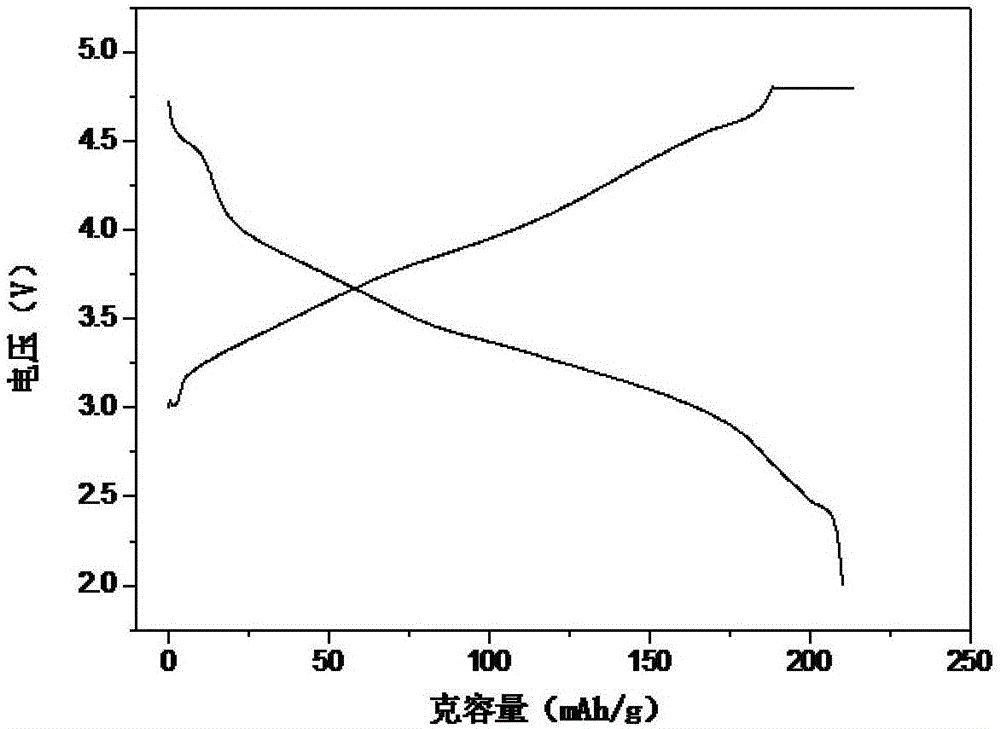

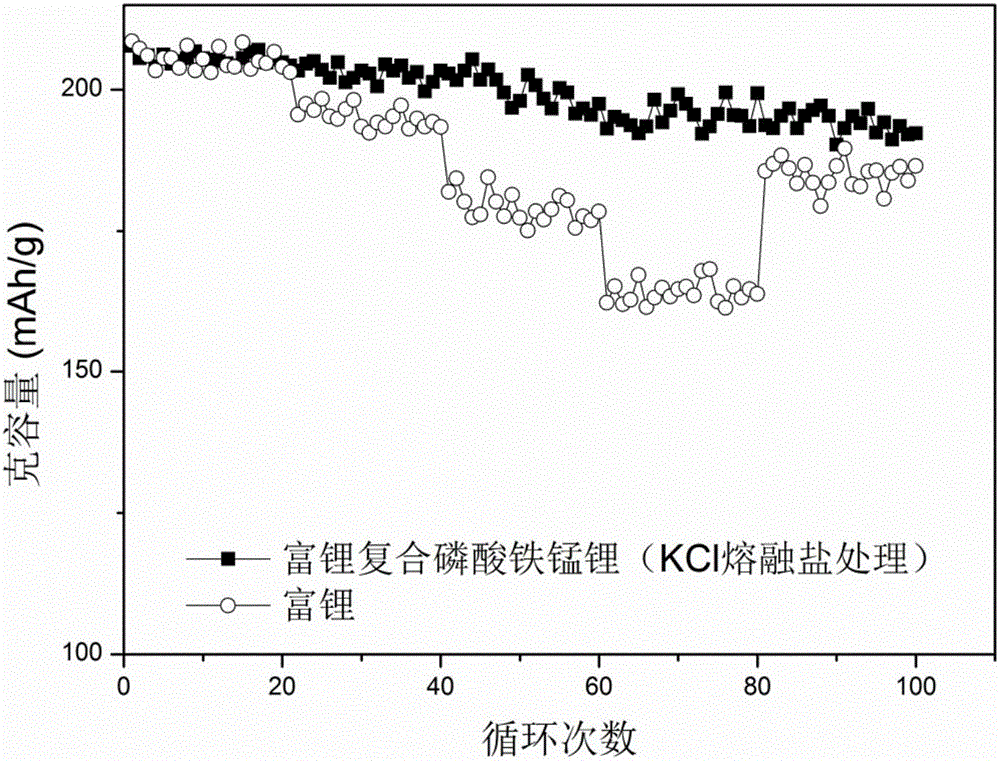

[0041] The lithium-rich manganese-based cathode material is Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 , lithium iron manganese phosphate material is LiFe 0.7 mn 0.28 (Mg+Ti) 0.02 PO 4 / C, fully mixed according to the mass ratio of lithium-rich manganese-based positive electrode material to carbon-composite lithium iron manganese phosphate of 99:1.

[0042] The average particle size of the secondary particle size of lithium iron manganese phosphate material is 3um, and the carbon content is LiFe y mn 1-y m z PO 4 3% of the mass of / C.

[0043] The preparation method of the composite cathode material is as follows: accurately weigh the lithium-rich manganese-based cathode material Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 and composite components lithium iron manganese phosphate LiFe 0.7 mn 0.28 (Mg+Ti) 0.02 PO 4 / C, use a planetary ball mill according to the ball-to-material ratio of 3:1, and perform ball milling and dry mixing at a speed of 200r / min for 2 hours and mix w...

Embodiment 2

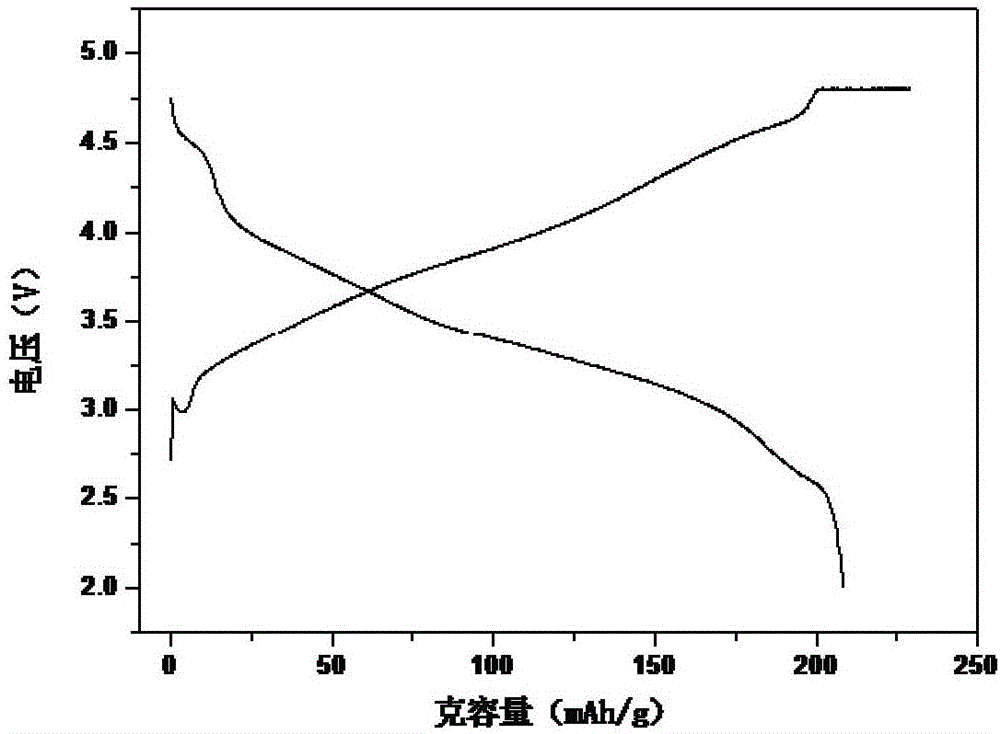

[0048] The lithium-rich manganese-based cathode material is Li 1.1 mn 0.1 Ni 0.9 o 2.1 , lithium iron manganese phosphate material is LiFe 0.9 mn 0.0994 (Mg+Ti) 0.006 PO 4 / C, fully mixed according to the mass ratio of lithium-rich manganese-based positive electrode material to carbon-composite lithium iron manganese phosphate of 99.5:0.5.

[0049] The average particle size of the secondary particle size of lithium iron manganese phosphate material is 8um, and the carbon content is LiFe y mn 1-y m z PO 4 2% of the mass of / C.

[0050] The preparation method of the composite cathode material is as follows: accurately weigh the lithium-rich manganese-based cathode material Li 1.1 mn 0.1 Ni 0.9 o 2.1 and composite components lithium iron manganese phosphate LiFe 0.9 mn 0.0994 (Mg+Ti) 0.006 PO 4 / C, manual grinding after high-speed mixing, fully mixed and baked in an oven at 80°C; accurately weigh the prepared mixture and molten salt NaCl according to the molar r...

Embodiment 3

[0052] The lithium-rich manganese-based cathode material is Li 1.9 mn 0.9 co 0.1 o 2.9 , lithium iron manganese phosphate material is LiFe 0.9 mn 0.071 (Mg+Ti) 0.029 PO 4 / C, fully mixed according to the mass ratio of lithium-rich manganese-based positive electrode material to carbon-composite lithium iron manganese phosphate of 95:5.

[0053] The average particle size of the secondary particle size of lithium iron manganese phosphate material is 50nm, and the carbon content is LiFe y mn 1-y m z PO 4 4% of the mass of / C.

[0054] The preparation method of the composite cathode material is as follows: accurately weigh the lithium-rich manganese-based cathode material Li 1.9 mn 0.9 co 0.1 o 2.9 and composite components lithium iron manganese phosphate LiFe 0.9 mn 0.071 (Mg+Ti) 0.029 PO 4 / C, after wet mixing with alcohol, manually grind, mix well and bake in an oven at 80°C; accurately weigh the prepared mixture and molten salt NaCl and KCl mixture according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com