Automatic feeding apparatus preparing pool for powdered activated charcoal

A technology of powder activated carbon and blending pool, which is applied in the direction of adsorption water/sewage treatment, etc. It can solve the problems of simple equipment, uneven pulping, and low dosing efficiency, so as to avoid deposition, improve the working environment, and increase the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

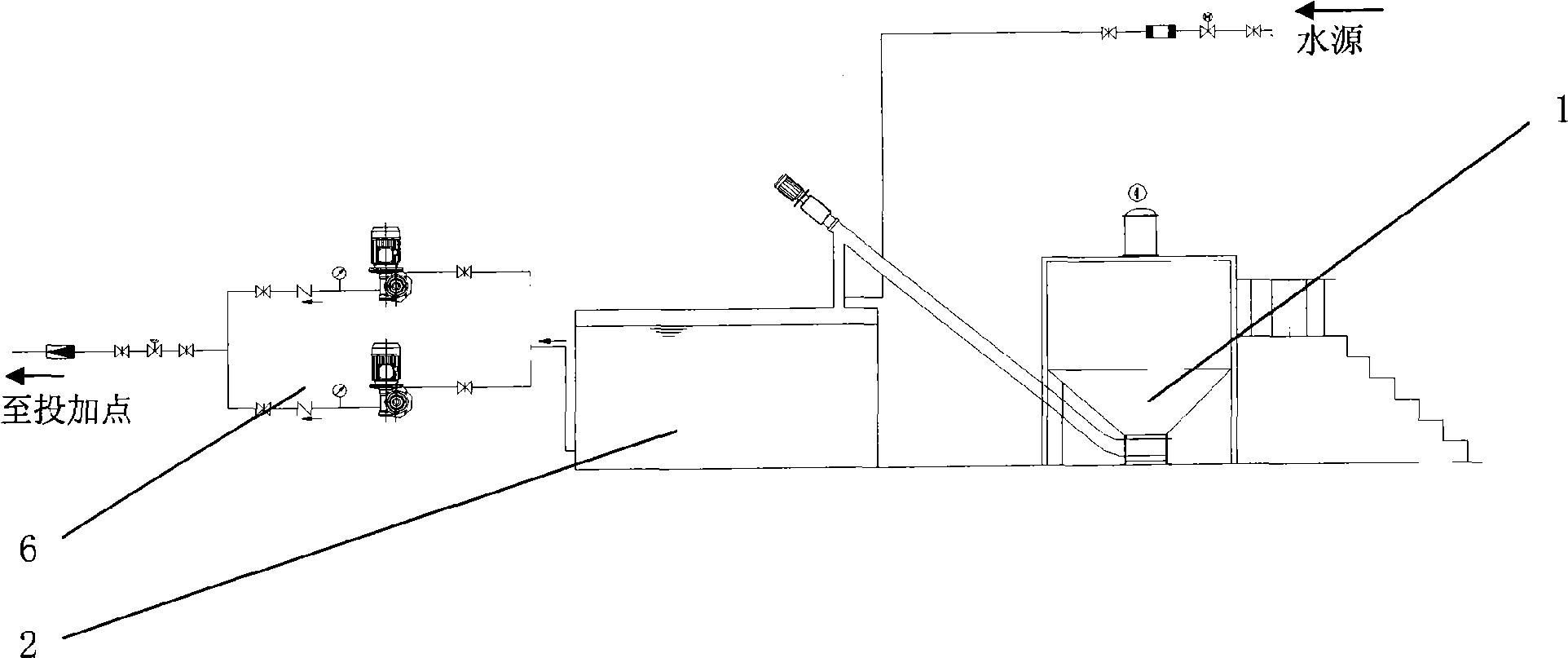

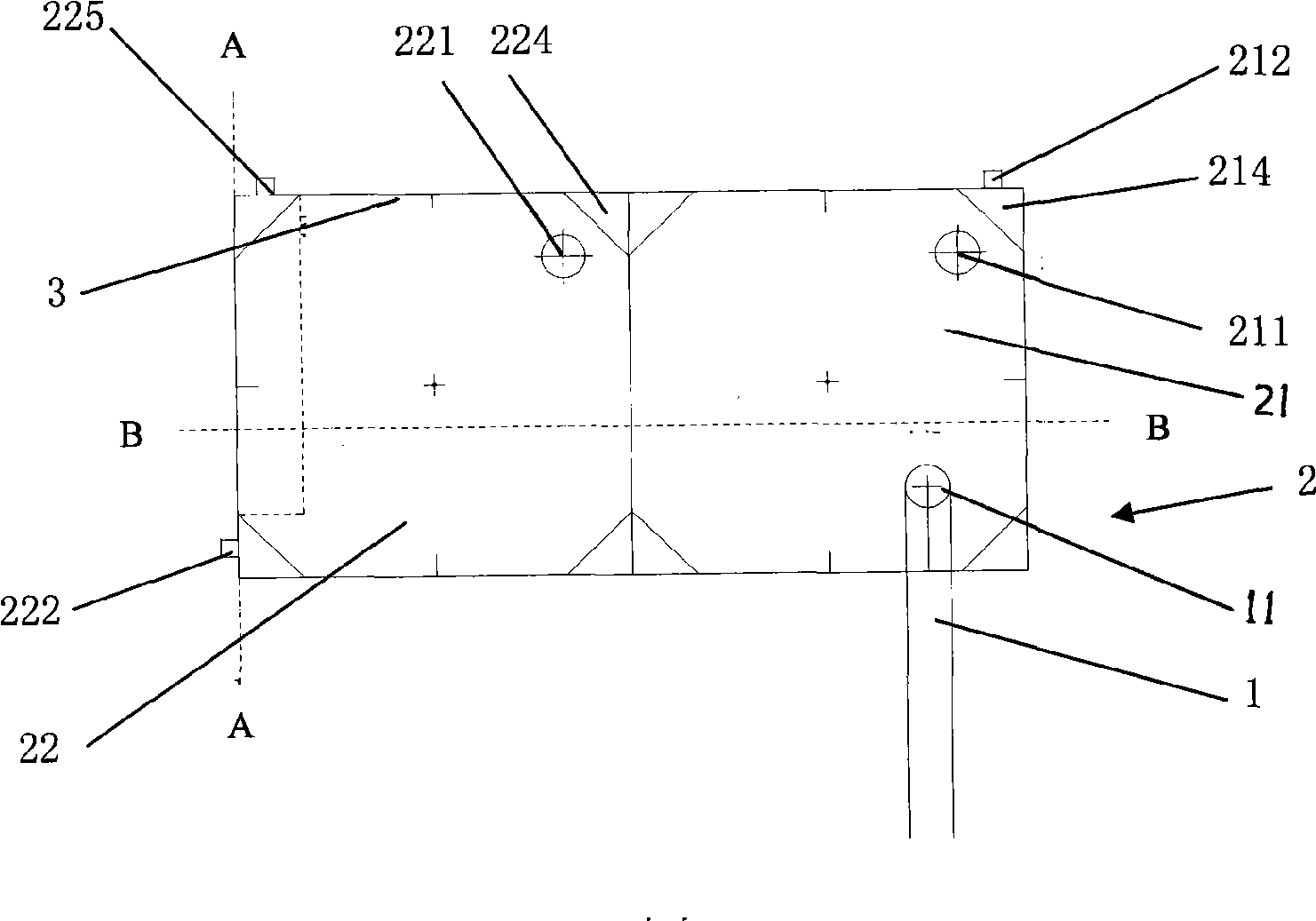

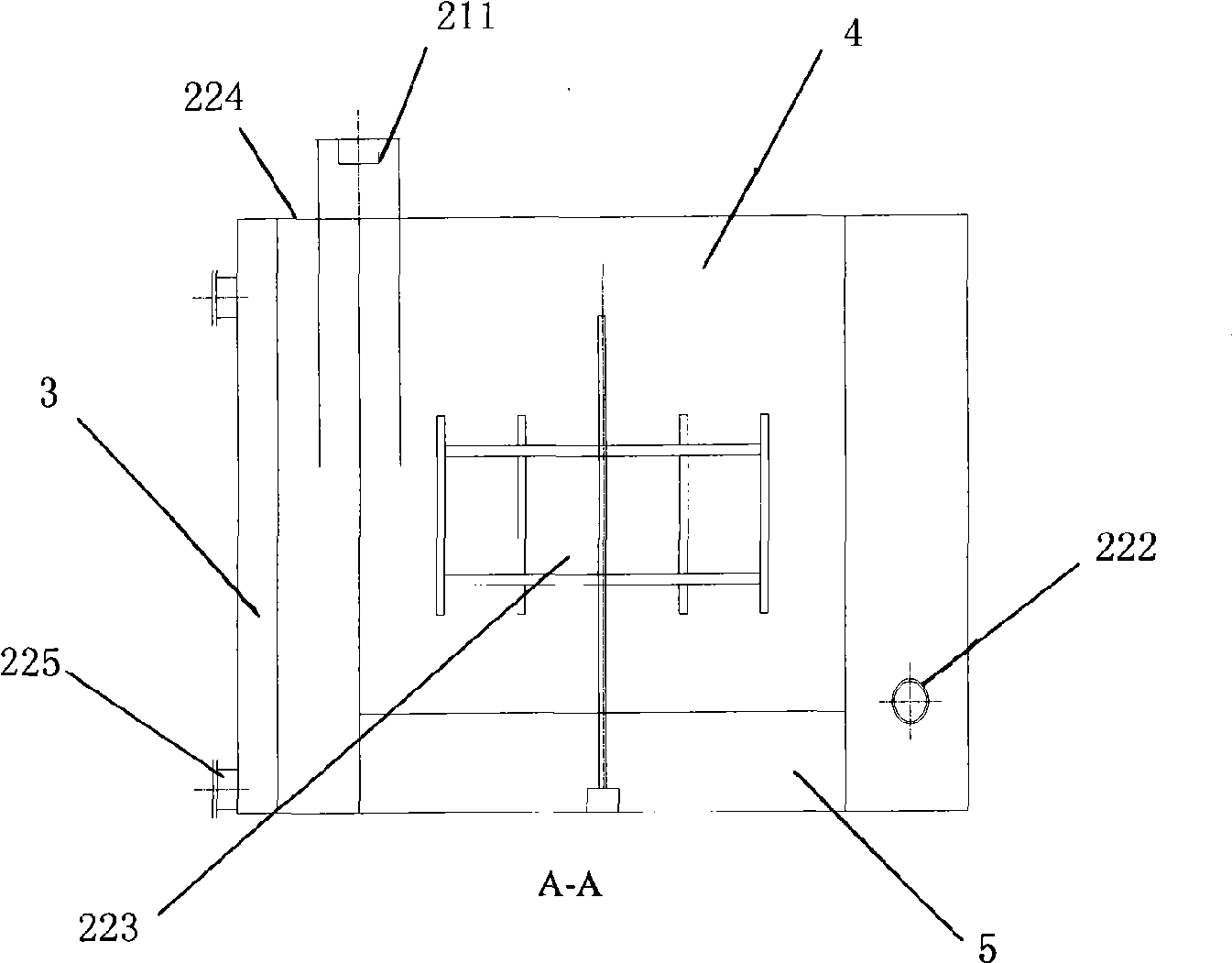

[0036] see figure 1 It is the structural representation of powder activated carbon automatic dosing equipment of the present invention, figure 2 It is a schematic diagram of the top view structure of the two-stage blending pool of the present invention, image 3 for figure 2 The A-A cross-sectional structure schematic diagram and Figure 4 for figure 2 As shown in the B-B cross-sectional structural schematic diagram of , a blending pool for automatic powdered activated carbon dosing equipment is a two-stage blending pool 2, including a first blending pool 21 and a second blending pool 22, and the ratio of its length, width, and height is 3. : 3: 2, the two-stage blending pool 2 is located at the front end of the dosing device 6, the first blending pool 21 and the second blending pool 22 are equipped with stirring devices, the feeding port 11 of the feeding device 1 is connected to the first blending The tanks 21 are sealed and connected, the first mixing tank 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com