Ultrasonic treatment chamber for preparing emulsions

a technology of ultrasonic treatment chamber and emulsion, which is applied in the direction of transportation and packaging, mechanical equipment, energy-based chemical/physical/physicochemical processes, etc., can solve the problems of human error, time, energy and money, and the conventional method of mixing phases into emulsions have several problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0102]In this Example, the ability of the ultrasonic mixing system of the present disclosure to mix an oil phase and aqueous liquid phase to form an oil-in-water type emulsion was analyzed. Specifically, the ability of the ultrasonic mixing system to mix dispersions of mineral oil into a diluted wet wipes solution was analyzed.

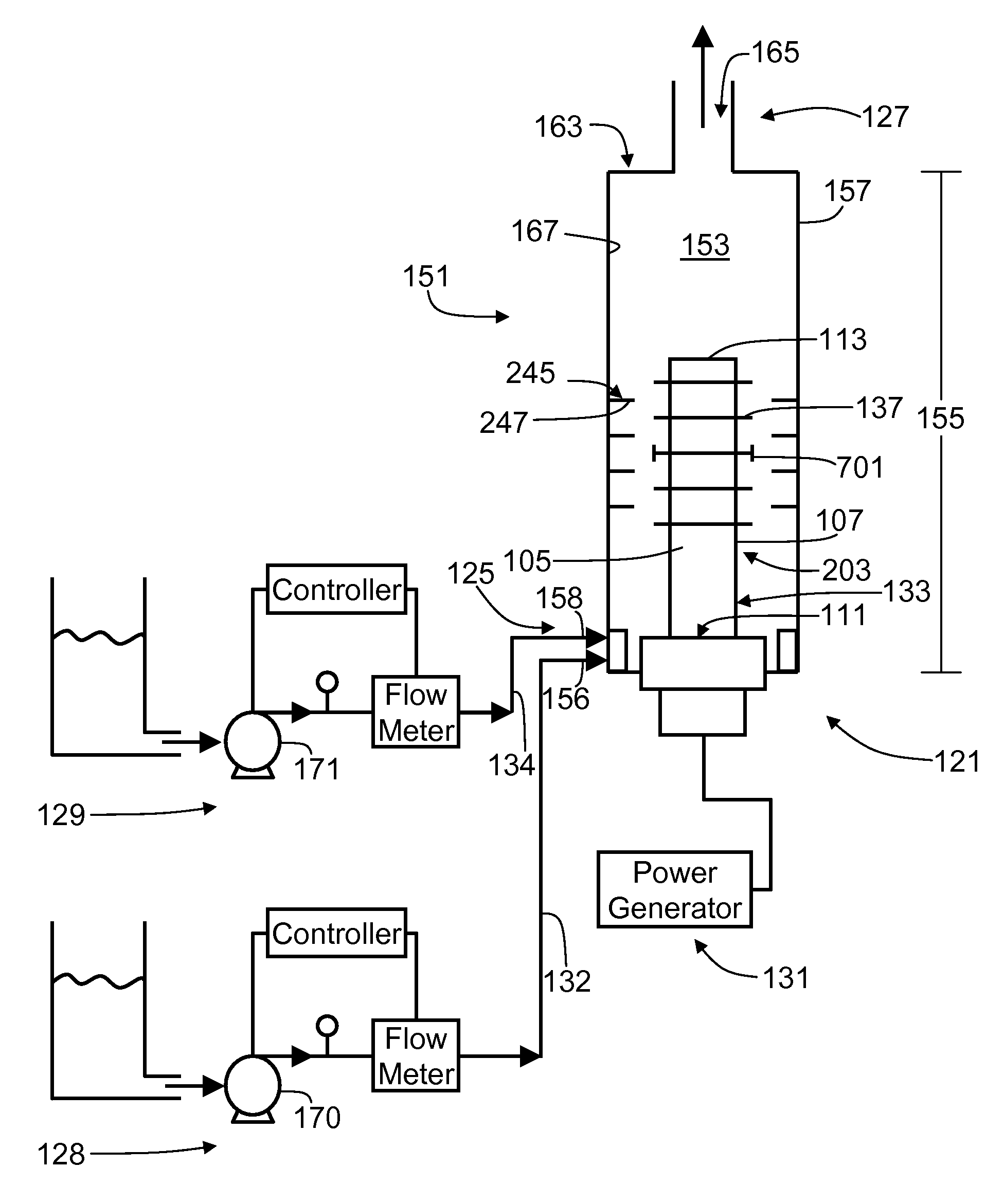

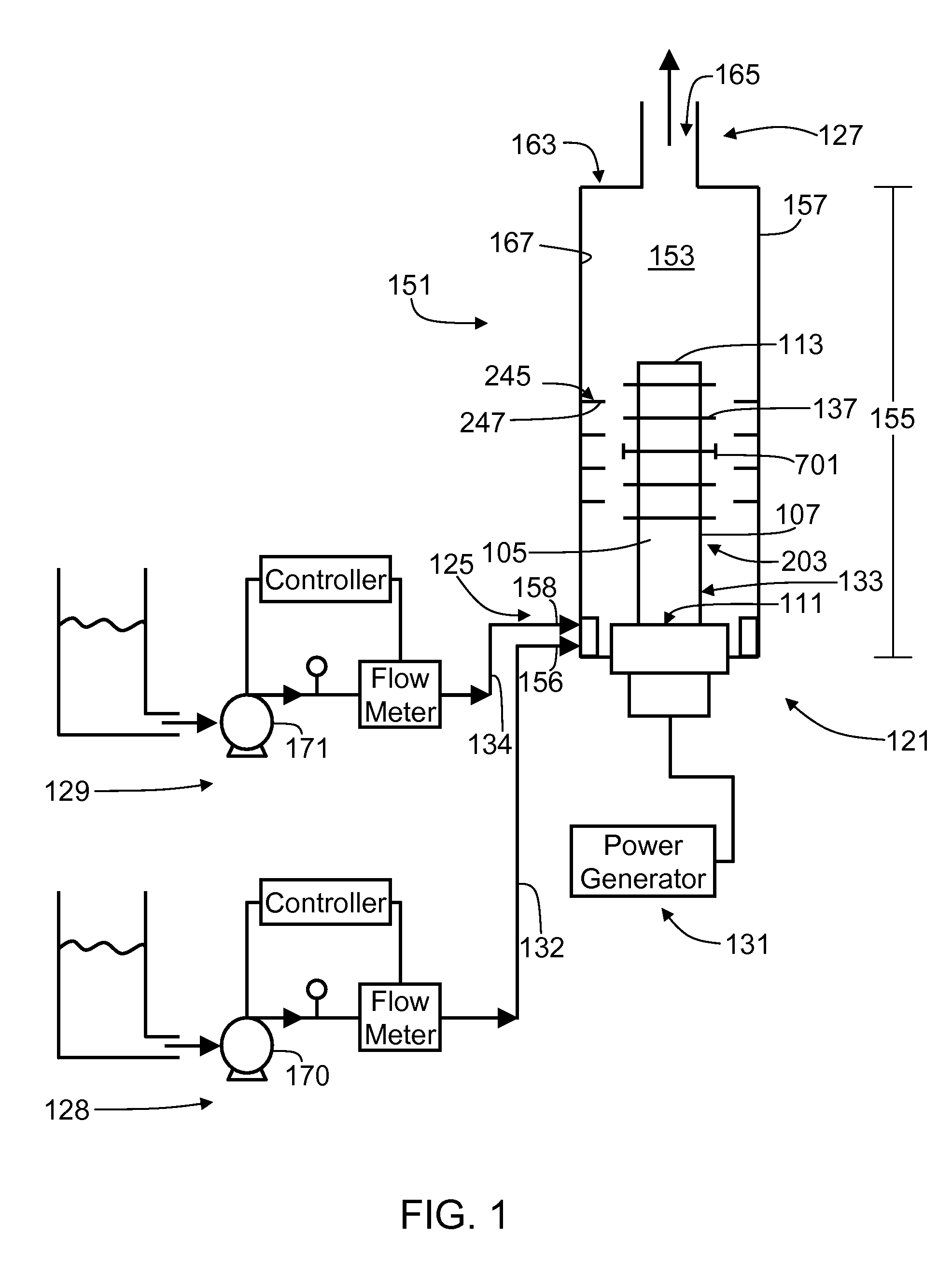

[0103]The diluted wet wipe solution included 4.153% (by weight) KIMSPEC AVE® (commercially available from Rhodia, Inc., Cranbury, N.J.) and 95.848% (by weight) purified water. The solution was prepared by mixing the KIMSPEC AVE® into water using a propeller mixer, available from IKA® EUROSTAR, IKA Works Co., Wilmington, N.C.), rotating at a speed of about 540 revolutions per minute (rpm). Four separate samples of the diluted wet wipe solution were prepared. The solution for each sample was delivered to a first inlet port of the ultrasonic mixing system of FIG. 1.

[0104]Additionally, a flow of mineral oil, available as PenrecoO Drakeol® LT mineral oil N.F. from ...

example 2

[0108]In this Example, the ultrasonic mixing system of the present disclosure was used to emulsify an oil phase into a water phase to produce an oil-in-water emulsion. The ability of the ultrasonic mixing system to prepare a stable oil-in-water emulsion was analyzed and compared to an oil-in-water emulsion prepared using a traditional cold mix procedure as described above.

[0109]Three oil-in-water emulsions were prepared. Specifically, the oil-in-water emulsions were prepared by mixing 1 part mineral oil (available as PenrecoO DrakeolO LT mineral oil N.F. from Penreco Co., The Woodlands, Tex.)) to 199 parts water for a mixing period of approximately 2 minutes. The first emulsion sample (Sample 1) was prepared using a propeller mixer (IKA® EUROSTAR, IKA Works, Co., Wilmington, N.C.) and using the standard cold mix batch procedure.

[0110]The other two oil-in-water emulsions (Samples 2 and 3) were prepared in the ultrasonic mixing system of FIG. 1. Specifically, to produce the oil-in-wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com