Method for dispersing highly viscous organosilicon mixture

A silicone and high-viscosity technology, applied in the direction of mixing methods, chemical instruments and methods, emulsification, etc., can solve problems such as difficulty in controlling the degree of crosslinking of silicone polyether, difficulty in ensuring consistency of emulsion stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the synthesis of series polyether

[0040] Table 2 Synthesized polyethers

[0041] serial number

[0042] Synthetic method: Add propenol or butanol and 0.3% KOH catalyst into polyether reactor. Then continue to heat up to around 130°C, first add ethylene oxide EO to it, then add propylene oxide PO, keep warm for 60 minutes after the addition, decolorize, neutralize and absorb and refine with acid clay to obtain a colorless viscous liquid.

Embodiment 2

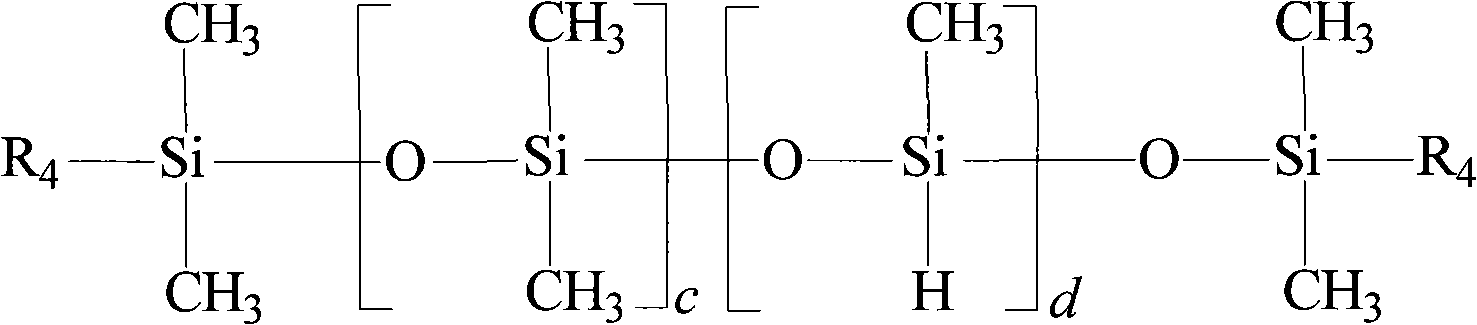

[0043] Embodiment 2: the low hydrogen-containing silicone oil of synthesizing high viscosity

[0044] Table 3 Synthetic high viscosity low hydrogen silicone oil

[0045]

[0046] High-viscosity low-hydrogen-containing silicone oil is prepared by chemical reaction under the action of an acidic catalyst according to the above-mentioned ratio of raw materials. The catalyst is sulfuric acid. After the reaction, the catalyst can be neutralized and then filtered. Hydrogen silicone oil S1, S2, S3, S4.

Embodiment 3

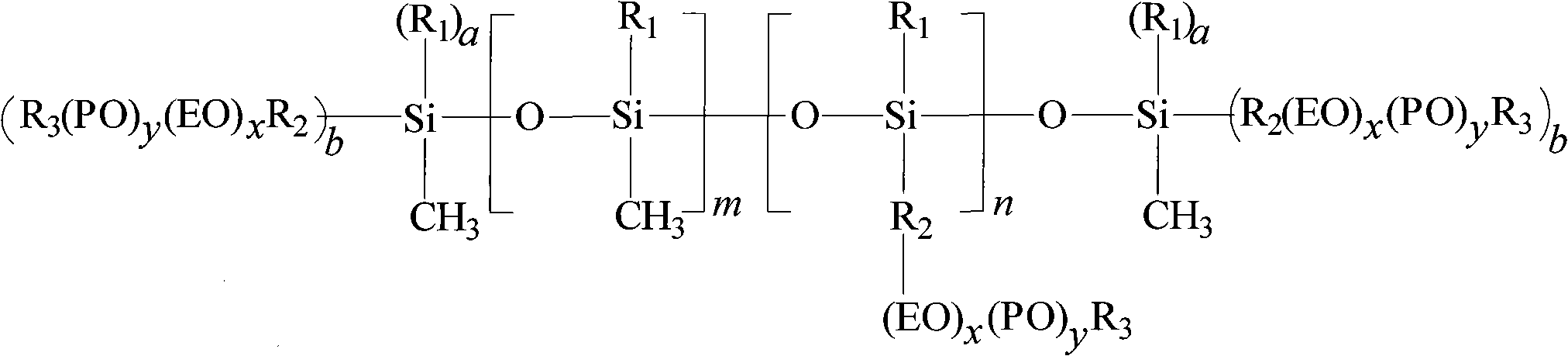

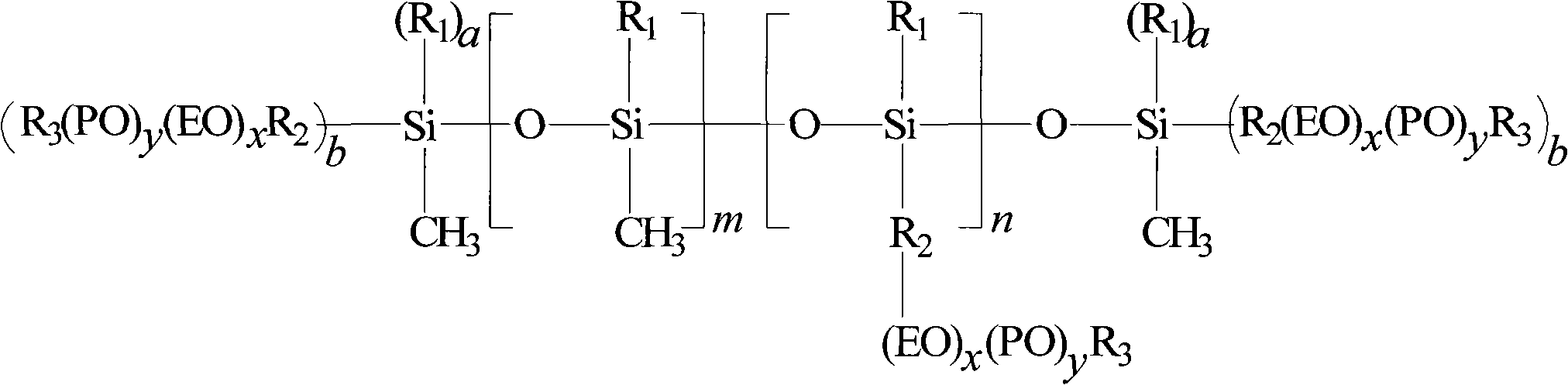

[0047] Example 3: Synthesis of high-viscosity silicone emulsifier (ie: silicon polyether)

[0048] The following silicone polyether emulsifiers can be prepared according to the hydrosilylation method or dehydrogenation condensation reaction:

[0049] Table 4 Synthesis of Silicone Polyethers

[0050] S1

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com