High internal phase gel-like zein Pickering emulsion and preparation method thereof

A technology of zein and high internal phase, applied in high internal phase gel-like zein Pickering emulsion and its preparation, field of zein Pickering emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Accurately weigh 1g of zein and dissolve it in 40ml of 70% ethanol solution;

[0041]Dissolve 0.2g of pectin in 100ml of distilled water, pour the zein alcohol solution into the pectin solution while homogenizing, homogenize at 6000rpm for 4min, and rotate at 40°C and 0.1Mpa vacuum for 40min; the obtained solution is at 10000rpm Centrifuge for 10 minutes to remove insoluble precipitates;

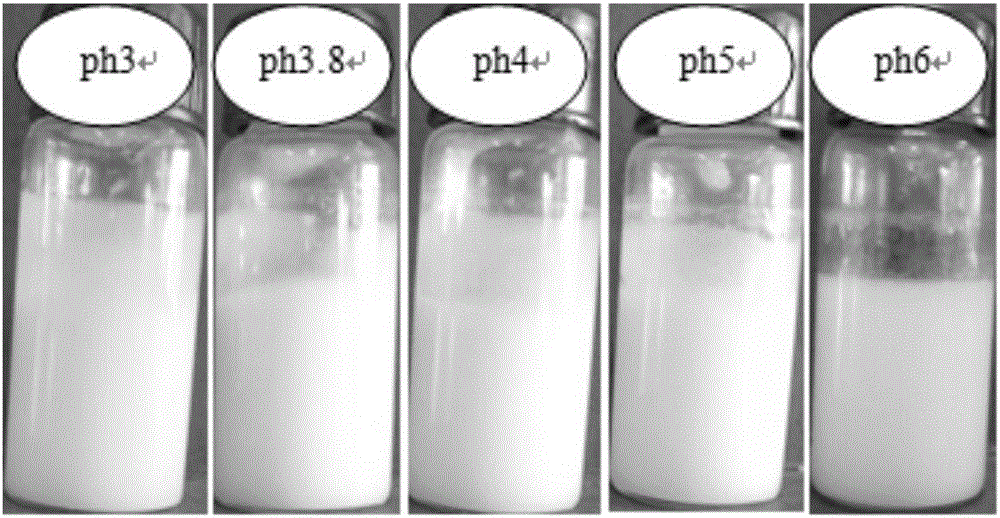

[0042] Adjust the pH value of the solution after centrifugation to be 3.0, 3.8 (original pH), 4.0, 5.0, and 6.0. Take 2ml of solutions with different pH values and mix them with 8ml corn oil for shear emulsification. The shear emulsification speed is 12000rpm and the time is 60s. A zein high internal phase Pickering emulsion was obtained.

[0043] In this embodiment, high internal phase Pickering emulsions with pH values of 3.0, 4.0, 5.0, and 6.0 are obtained by adjusting the pH value of the solution, and the state of the emulsion after being newly prepared and after 10 days is o...

Embodiment 2

[0054] Accurately weigh 1g of zein and dissolve it in 40ml of 70% ethanol solution;

[0055] Dissolve 0.2g of pectin into 100ml of distilled water, pour the zein alcohol solution into the pectin solution while homogenizing, homogenize at 6000rpm for 4min, rotate and evaporate at 40℃, 0.1Mpa vacuum for about 40min, so that the volume of the solution was 50 g, and the resulting solution was centrifuged at 10,000 rpm for 10 min to remove insoluble precipitates;

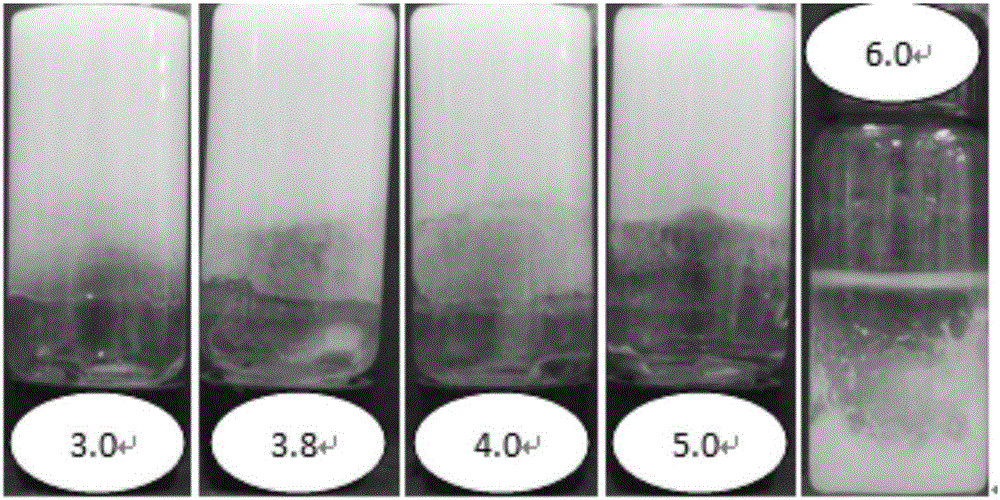

[0056] Adjust the pH of the solution after centrifugation to be 3.0, 4.0, and 5.0 respectively. Take 2ml of solutions with different pH values and mix them with 8ml of corn oil for shear emulsification. Pickering Lotion. Take 2ml of the emulsion and centrifuge at 10000rpm for 2min.

[0057] This embodiment characterizes its centrifugal stability by observing the state of the emulsion after centrifugation, such as Figure 5 shown.

Embodiment 3

[0063] Accurately weigh 1g of zein and dissolve it in 40ml of 70% ethanol solution;

[0064] Dissolve 0.5g of pectin into 100ml of distilled water, pour the zein alcohol solution into the pectin solution while homogenizing, homogenize at 6000rpm for 4min, and rotate at 40°C and 0.1Mpa vacuum for 40min; the obtained solution is at 10000rpm Centrifuge for 10 minutes to remove insoluble precipitates;

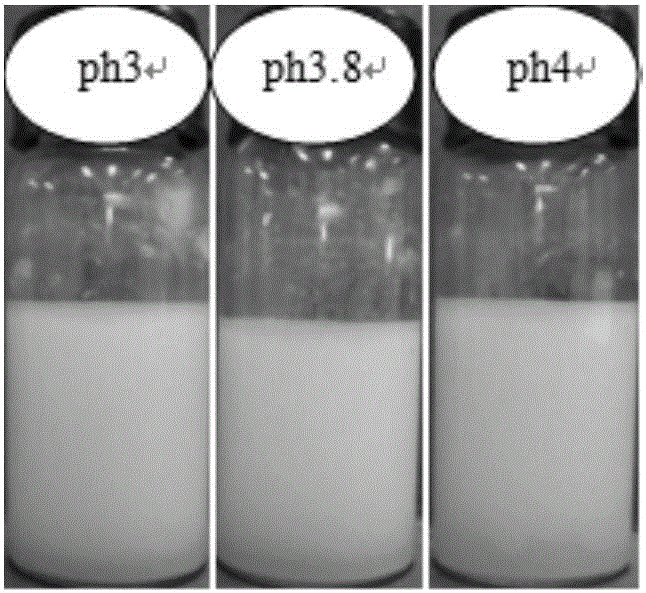

[0065] After adjusting the centrifugation, the pH value of the solution is 3.0, 3.8 (original pH), 4.0, 5.0 respectively, and 2ml of solutions with different pH values are mixed with 8ml corn oil respectively for shear emulsification, the shear emulsification speed is 12000rpm, and the time is 60s to obtain corn Glamin High Internal Phase Pickering Emulsion.

[0066] Take 2ml of the prepared emulsions with different pH to test the rheological properties respectively. The diameter of the plate used is 27.83, the temperature is 25°C, and the stress scanning frequency is set to 1Hz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com