Overall assembly type reinforcement printing construction method for 3D printing concrete structure

A concrete structure and 3D printing technology, which is applied in building construction, construction, and building material processing, etc., can solve the problems of unable to form a reinforced skeleton, and it is difficult to ensure the rigidity of the reinforced skeleton and the cooperative performance of the strong concrete structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

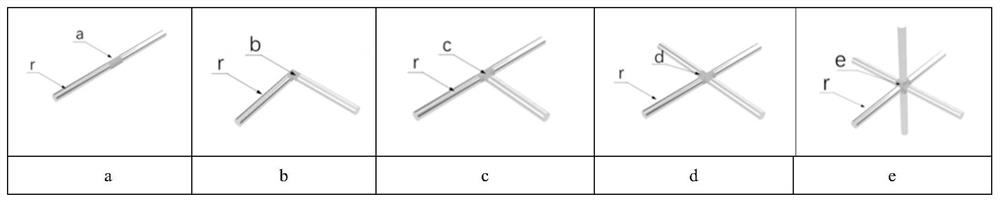

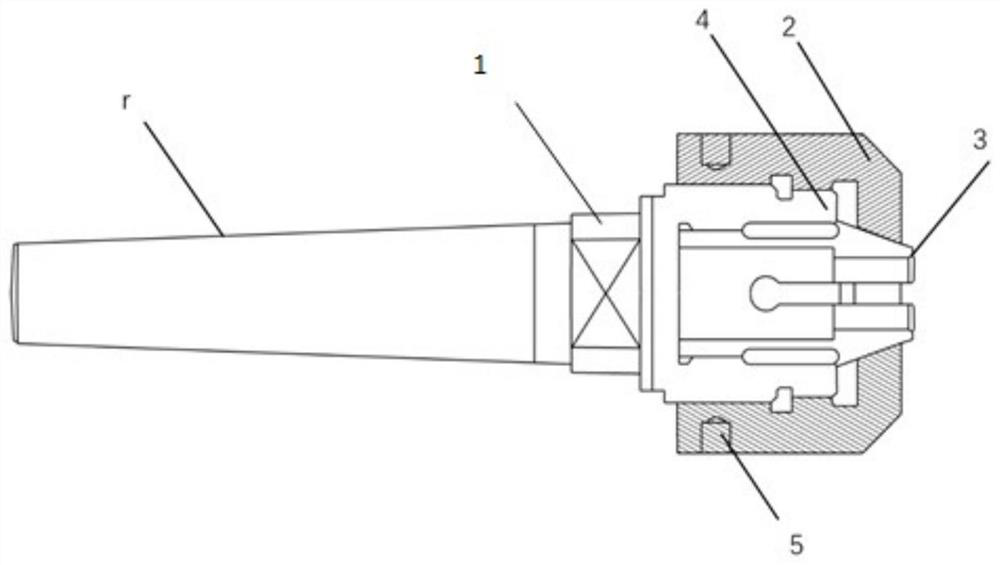

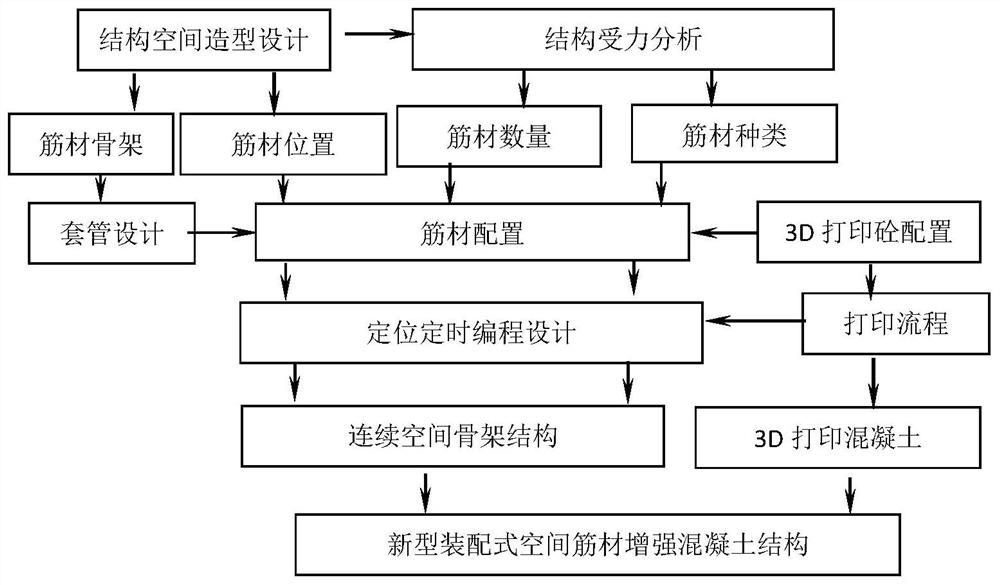

[0043] by Figure 4 and Figure 7 (beam-beam, r-reinforcing bar, a-one-way connection casing, m-construction robot arm, P-printed concrete, c-three-way connection casing, X-printing direction, Z stacking direction) beam member As an example, the step-by-step instructions for printing and building:

[0044] 1. Determine the structural form and spatial structure according to the structural and functional requirements. The beam-type member bears a large bending moment, and the bottom of the beam produces a large tensile stress, so more reinforcements need to be arranged to meet the structural force requirements. Carry out mechanical calculation and analysis of structural components, and determine the material, total amount, layout position and strength, diameter, surface shape, distance and spacing from the outer edge of the concrete layer to be added to the structural component according to the limit state of the structural bearing capacity and the limit state of normal servic...

Embodiment 2

[0049] by Figure 5 and Figure 8 ((plate-plate, r-reinforcement, d-four-way connection casing, c-three-way connection casing, m-construction robot arm, P-printing concrete, X-printing direction, Z stacking direction) the plate component is For example, the step-by-step instructions for printing and building:

[0050] 1. Carry out mechanical calculation and analysis on the slab, and determine the material, total amount, layout position and strength, diameter, surface shape, distance from the outer edge of the concrete layer and Spacing; and determine the position, quantity and form of the connecting sleeve according to the position of the intersection point and the number of intersections of the reinforcement. In this embodiment, the forms of connecting sleeves used include one-way connecting sleeves and three-way connecting sleeves.

[0051] 2. Determine the printing process of concrete, reinforcements and connection sleeves according to the overall structure of beam-type ...

Embodiment 3

[0055] by Figure 6 and Figure 9 (column-column, e-multi-directional casing, m-construction robot arm, r-reinforcement) column components as an example, the step-by-step instructions for printing and construction:

[0056] 1. Carry out mechanical calculation and analysis of the column, and determine the material, total amount, layout position and strength, diameter, surface shape, and distance from the outer edge of the concrete layer to be added to the structural member according to the limit state of the structural bearing capacity and the selection of the normal service limit state and spacing; and determine the position, quantity and form of the connecting sleeve according to the position of the intersection point and the number of intersections of the reinforcement. In this embodiment, the forms of connecting sleeves used include one-way connecting sleeves and three-way connecting sleeves.

[0057] 2. Determine the printing process of concrete, reinforcements and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com