Method for preparing blocky ferric trichloride

A technology of ferric trichloride and ferric chloride hexahydrate, which is applied in the direction of ferric halide, etc., can solve the problems of low product purity, short shelf life, and easy deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

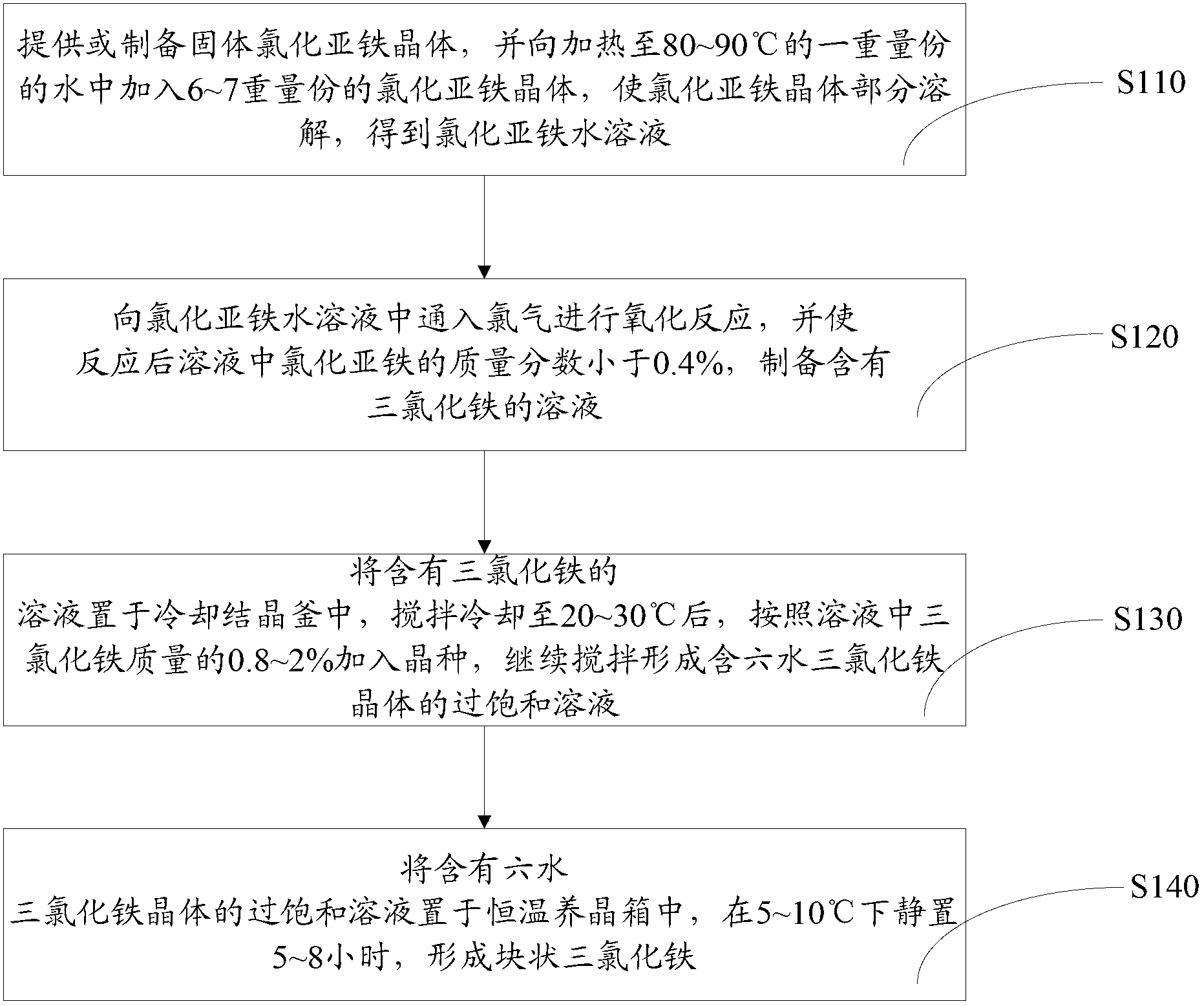

[0024] Such as figure 1 Shown, the preparation method of the bulk ferric chloride of an embodiment mainly comprises the following steps:

[0025] Step S110, providing or preparing solid ferrous chloride crystals, and adding 6-7 parts by weight of solid ferrous chloride crystals to one part by weight of water heated to 80-90°C to partially dissolve the solid ferrous chloride crystals , to obtain ferrous chloride aqueous solution.

[0026] In this embodiment, the ferrous chloride raw material in the ferrous chloride aqueous solution is solid ferrous chloride tetrahydrate crystal, which is mainly based on iron and steel pickling waste liquid as raw material, and is added to the iron and steel pickling waste liquid Elemental iron is obtained by filtering, evaporating and concentrating, cooling and crystallizing, and centrifuging. Iron and steel pickling waste liquid contains a lot of Fe 2+ , acid and some impurity metal ions (such as Na + 、K + , Mg 2+ 、Ni 2+ , Pb 4+ etc.),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com