Comprehensive recycling process for valuable metal roasting-cyaniding gold-containing tailing

A technology for valuable metals and tailings, which is applied in the field of roasting - comprehensive recovery of cyanidation gold-containing tailings, can solve the problems of secondary environmental pollution, low recovery rate, poor impurity removal effect, etc., and achieves short technological process. , High promotion value, easy promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

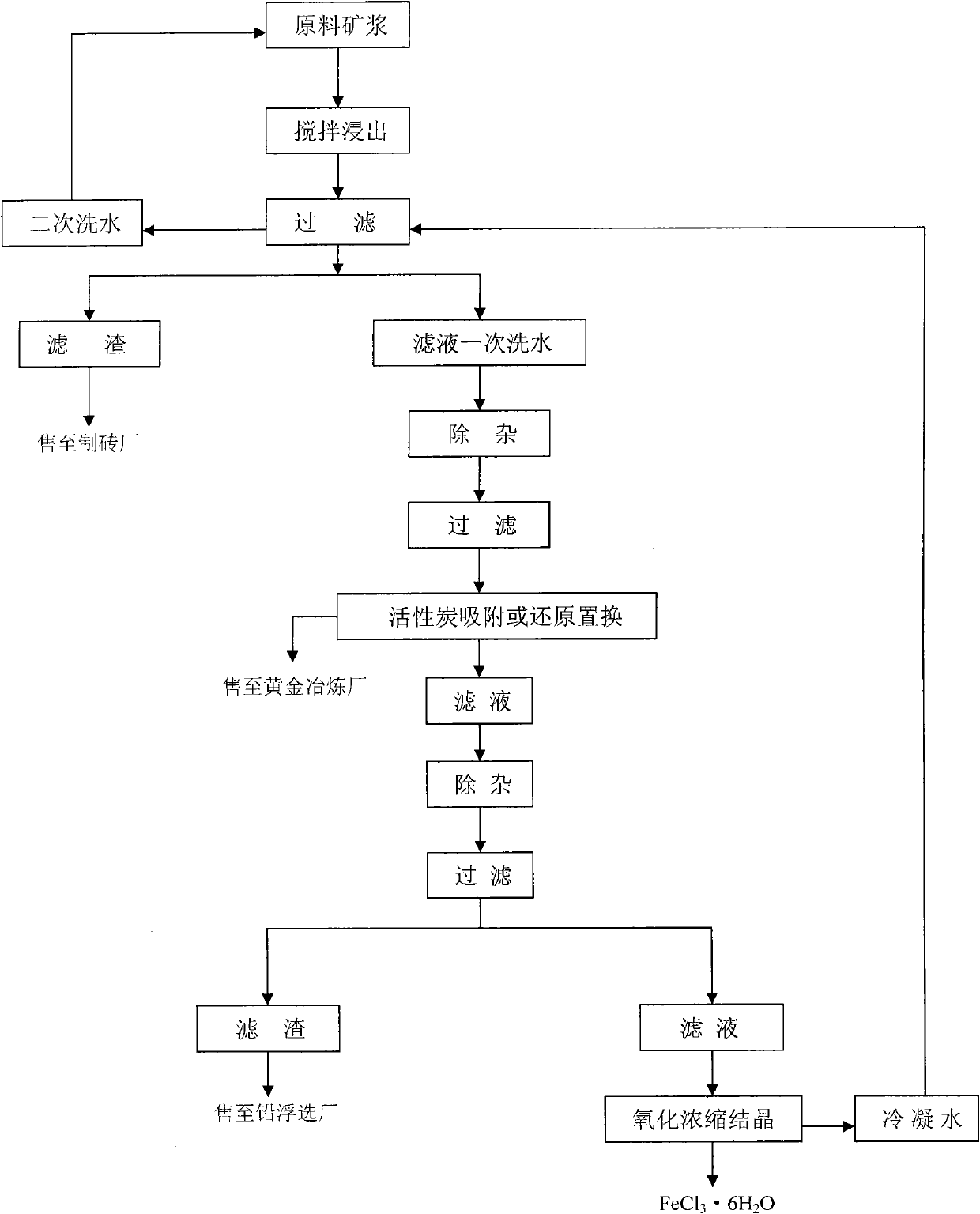

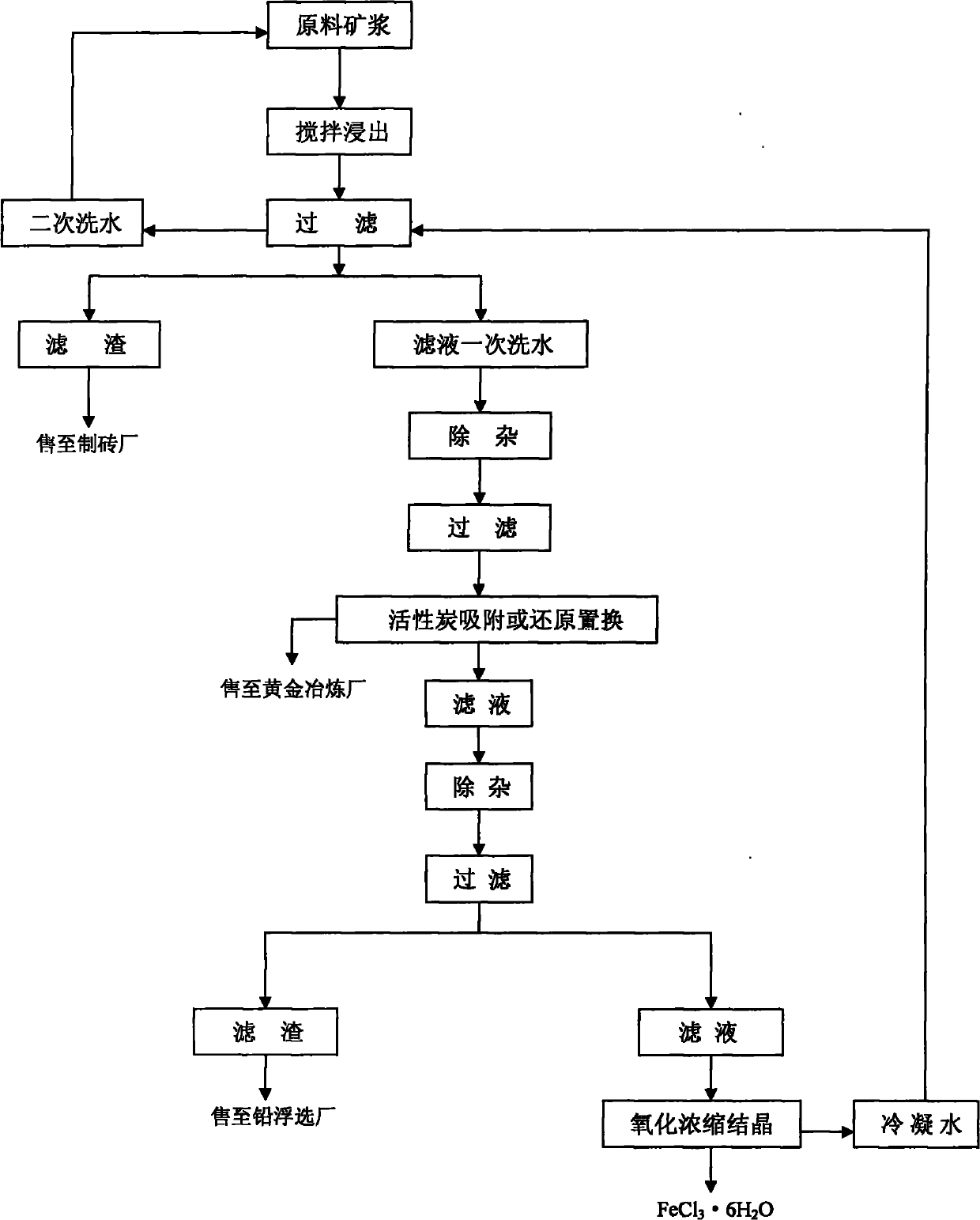

Image

Examples

Embodiment Construction

[0033] In order to better illustrate the present invention, give examples as follows:

[0034] Get 500 grams of tailings after roasting-cyanidation and put them into a three-neck bottle (the main components of tailings are shown in Table 1), add 20% hydrochloric acid solution by mass percentage with a solid-to-liquid ratio of 1:3, heat to 120 ° C, and continuously Stirring and leaching for 8 hours, at this time, the leaching rate of sampling detection Fe was more than 95%; stop heating, then add 20g of sodium hypochlorite, and simultaneously feed chlorine gas continuously, and stir for 2 hours; the reaction was finished and washed and filtered, and now the filter residue sample was taken to detect the Au content. Below 0.1g / t, the content of Ag is 6.7g / t, the content of Pb is 0.06%, the content of Fe is 2.3%, and the content of Si is 85.3%. / t, Ag3.1g / t; Take 500ml of the filtrate after activated carbon adsorption, add 10g of reduced iron powder, heat to 100°C, stir and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com