Process for preparing poly ferric chloride

A technology of polymerized ferric chloride and polymerized ferric sulfate, which can be used in the fields of ferric halide, chemical recovery, flocculation/sedimentation water/sewage treatment, etc., and can solve the problems of good water purification effect and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

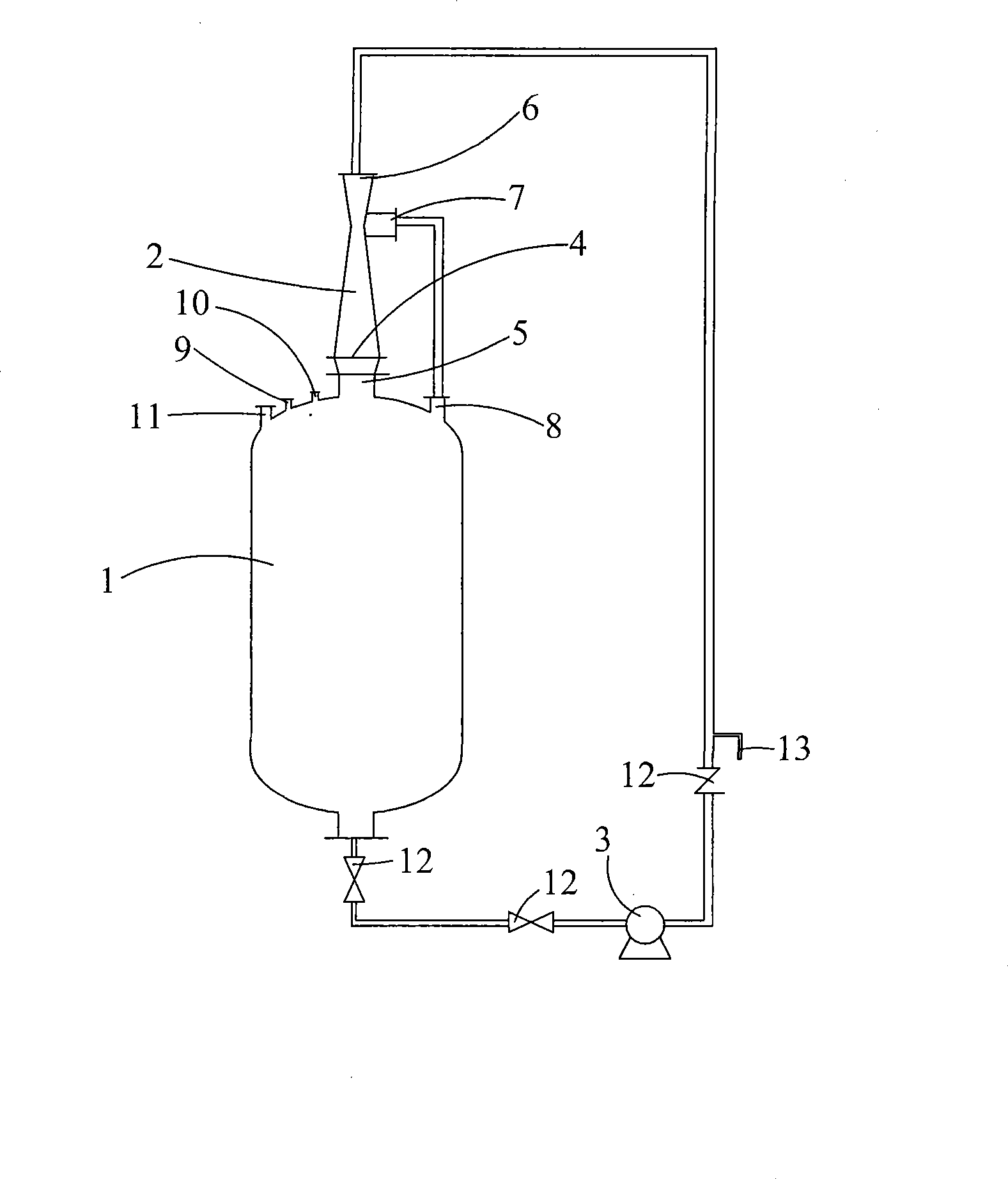

[0090] figure 1 It is a structural diagram of the reactor device in the preparation method of the present invention. Such as figure 1 As shown, the reactor device of the present invention includes a reactor body 1, a pipeline hydraulic injector 2, a circulating pump 3 and connecting pipelines thereof.

[0091] The pipeline hydraulic injection port 4 is connected with the top opening 5 of the oxidation reactor body 1; the circulation pump 3 connects the bottom outlet of the oxidation reactor body 1 with the pipeline hydraulic injector inlet 6 through a pipeline to form a closed circulation system; the pipeline hydraulic The side opening 7 of the injector is connected with the opening 8 on the top side of the oxidation reactor body through a pipeline. The restrictor valve 12 is a liquid flow control valve; after the reaction is complete, the reaction liquid is transferred to the sedimentation tank or filtering device through the outlet 13.

[0092] The catalyst is added throu...

Embodiment 2

[0094] The waste hydrochloric acid liquid is added to the acid-resistant reaction kettle, and iron scraps are added according to the conversion of the iron content of the raw materials (the percentage of total iron is 90%), so that the iron content in the product is 10% (w / w), and heat generation occurs with hydrochloric acid The heat generated by the reaction is preheated, and the catalyst NaNO is added at the same time 3 . Then use the circulating pump and the pipeline hydraulic injector to circulate for 3 hours, fully mix the feed liquid and the total amount of 1920L oxygen for contact reaction, and then enter the sedimentation tank, and the product obtained through natural precipitation and separation is polyferric chloride.

Embodiment 3

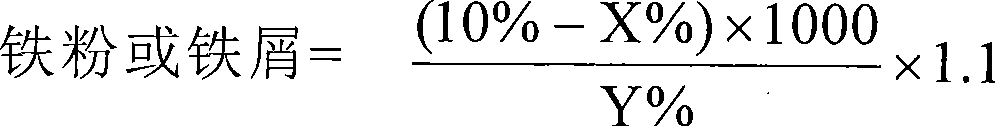

[0096] Add the waste hydrochloric acid pickling solution with an iron content (referring to the percentage of total iron) of 7.0% (w / v) into the acid-resistant reaction kettle, and then add the iron content (referring to the percentage of total iron 90%) to each ton of waste liquid The iron powder is about 48.9kg, the acid and iron react, the heat generated is preheated, and the catalyst NaNO is added at the same time 3 And feed 1920L of oxygen, use the circulating pump and pipeline hydraulic injector to circulate for 4 hours, fully mix the feed liquid and oxygen for contact reaction, enter the intermediate pool, and then filter and separate the obtained filtrate through the plate and frame filter press, which is the iron content ( Refers to the polyferric chloride product containing 10% total iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com