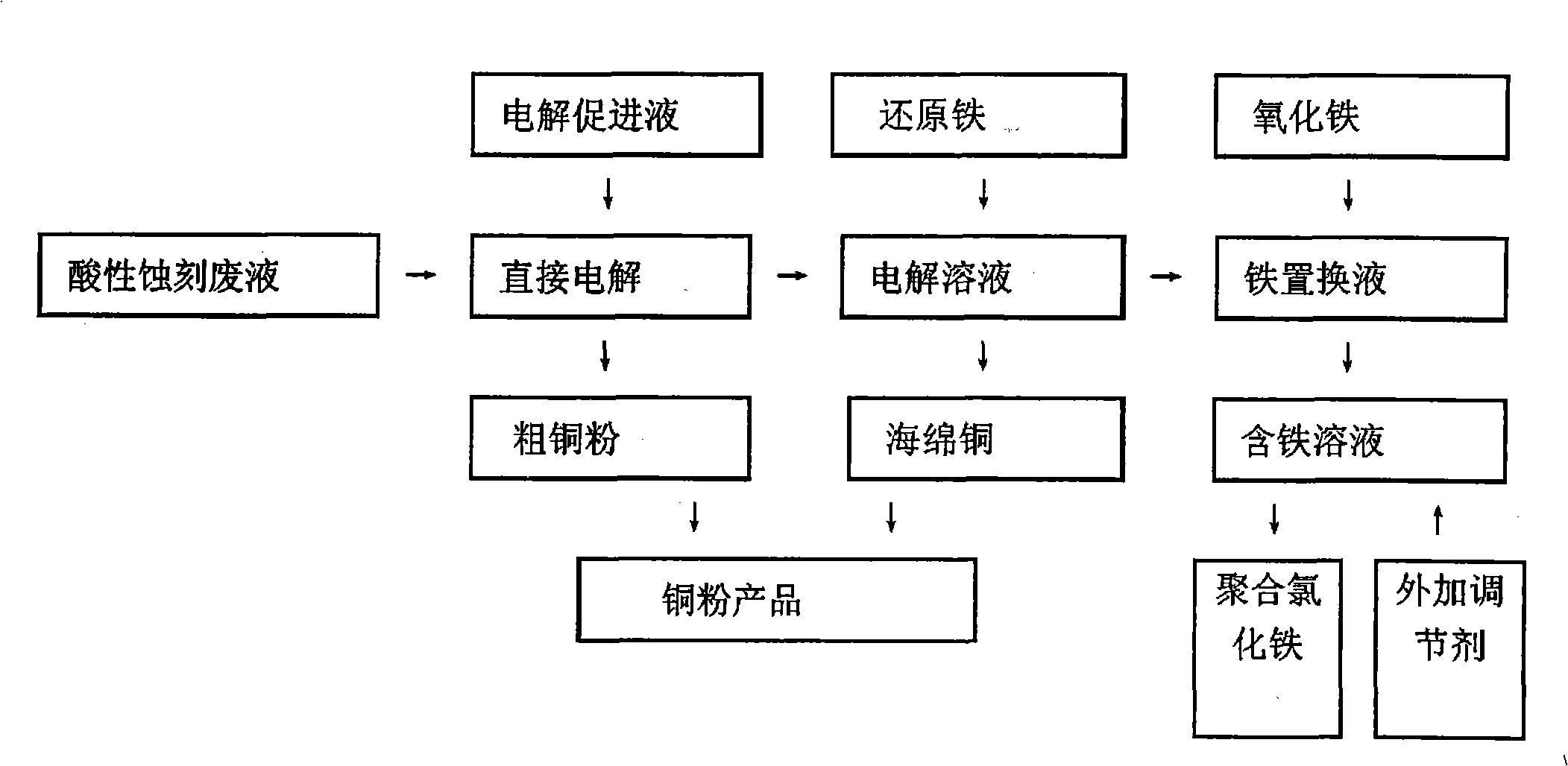

Method for extracting copper from printed circuit board acidic spent etching solution and preparing poly ferric chloride

A technology of acidic etching waste liquid and polyferric chloride, which is applied in the field of resource utilization of industrial waste and water environment treatment, can solve problems such as inapplicability, and achieve the effects of reducing recycling costs, low corrosion, and high recycling purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] ② Preparation of iron-containing liquid

[0064] Add iron oxide to the solution replaced by reduced iron, and prepare iron-containing liquids with different concentrations by adding exogenous iron-containing substances according to the concentration requirements of the prepared iron-containing liquid. The reaction formula of this step is:

[0065] Fe 2 o 3 +6H + →2Fe 3+ +3H 2 o

[0066] ③ Preparation of Polyferric Chloride

[0067] The prepared iron-containing liquid undergoes a series of oxidation, hydrolysis and polymerization reactions to obtain polyferric chlorides with different iron contents.

[0068] Fe 3+ Hydrolyzed to varying degrees, Fe 3+ and OH - The indicators of products with different proportions are different, and the following reactions mainly occurred:

[0069] wxya 3+ +yH 2 O → Fe x [(OH) y ] (3x-y)+ +yH +

[0070] Different hydrolysates recombined with Cl - , mainly the following reactions occurred:

[0071] Fe x [(OH) y ] (3x-...

Embodiment 1

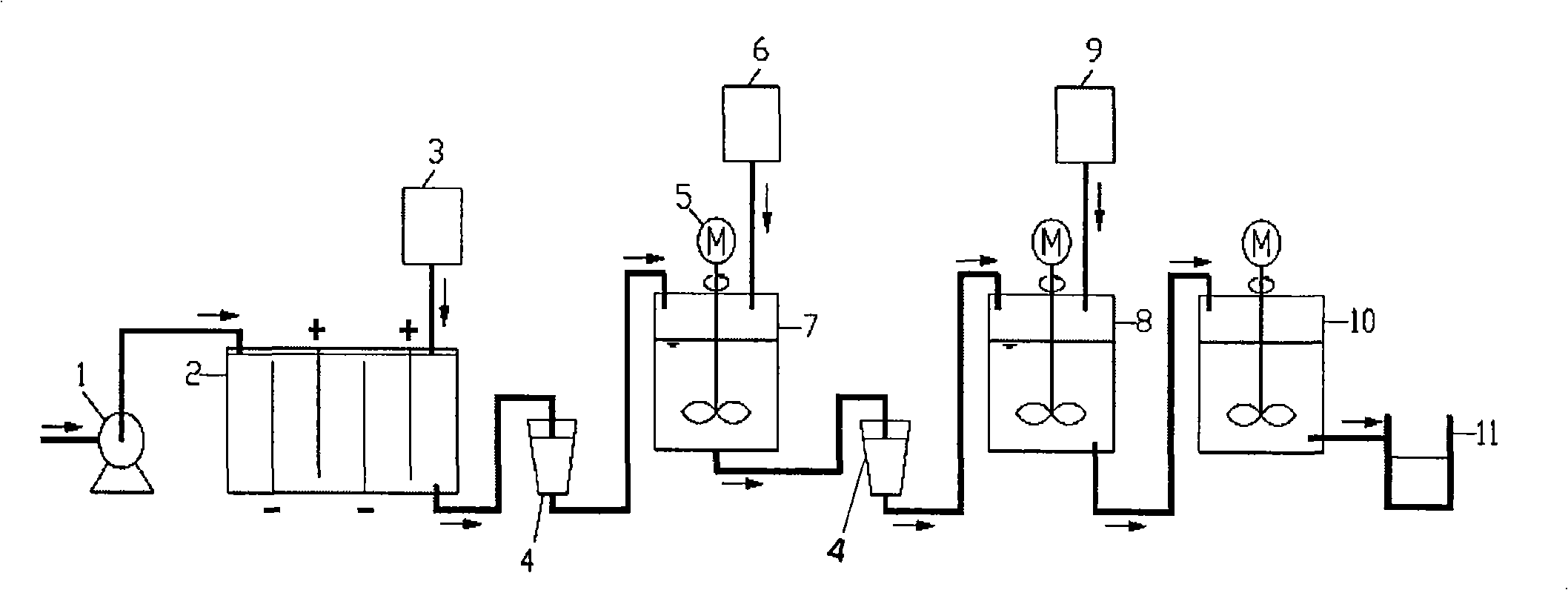

[0076] Such as figure 2 shown. Use an acid-resistant corrosion pump 1 to reduce the copper content to 2.0-100.0g / L and the density to 1.05-1.35kg / m 3 PCB etching waste liquid 2.0m 3 Import the electrolytic cell 2, and add the electrolytic promoting liquid through the electrolytic promoting liquid device 3, turn on the power and directly electrolyze copper, when the concentration of copper ions in the acidic etching waste liquid is lower than 0.50g / L, cut off the power and end the electrolysis (the electrolysis time is 5.0~10.0h), after the electrolysis is finished, the electrolyzed copper powder is collected through the copper powder filter 4.

[0077] Lead the electrolytic copper filtrate into the copper replacement device 7, add reduced iron through the reduced iron device 6, turn on the impeller stirring device 5 for uniform mixing, and continuously monitor the copper content in the electrolytic filtrate until it drops to the lowest concentration or is completely replace...

Embodiment 2

[0082] Such as figure 2 shown. Use an acid-resistant corrosion pump 1 to reduce the copper content to 2.0-100.0g / L and the density to 1.05-1.35kg / m 3 PCB etching waste liquid 2.0m 3 Import the electrolytic cell 2, and add the electrolytic promoting liquid through the electrolytic promoting liquid device 3, turn on the power and directly electrolyze copper, when the concentration of copper ions in the acidic etching waste liquid is lower than 0.50g / L, cut off the power and end the electrolysis (the electrolysis time is 5.0~10.0h), after the electrolysis is finished, the electrolyzed copper powder is collected through the copper powder filter 4.

[0083] Lead the electrolytic copper filtrate into the copper replacement device 7, and add reduced iron through the reduced iron device 6, turn on the impeller stirring device 5 for uniform mixing, and continuously monitor the copper content in the electrolytic filtrate, when it drops to the lowest concentration or is completely rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com