Method for recycling effective ingredients of multi-component high-concentration small-flow intermittent organic waste gas

A technology of organic waste gas and active ingredients, applied in organic waste gas recovery and treatment device, intermittent organic waste gas active ingredient device, high concentration, recovery of multi-component, small flow field, to achieve automatic control, high automatic control, low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

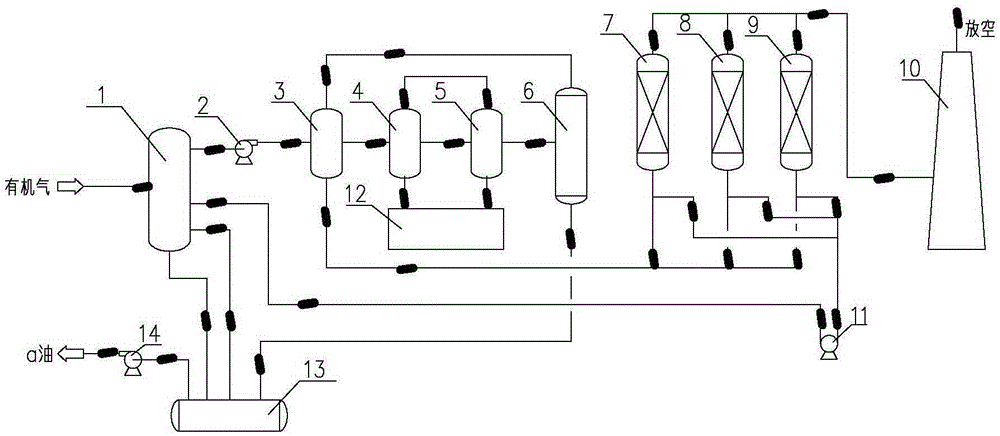

[0016] This embodiment is a method for recovering active components of multi-component, high-concentration, low-flow, intermittent organic waste gas. The equipment is connected as figure 1 As shown, for platform oil and gas recovery, multi-component, high-concentration, low-flow intermittent organic waste gas has a complex composition, mainly composed of alkanes, olefins, and non-methane total hydrocarbons; the concentration changes frequently, ranging from 100 to 90,000mg / l ;The flow rate is small and intermittent, and its variation range is 10~10000m 3 ,Specifically:

[0017] When the crane tube starts to work, the booster fan set in the system induces air, and the oil and gas first enter the buffer tank to maintain the buffer tank in a slight negative pressure state. Pressure is adjusted. After the device starts, adjust the oil and gas intake according to the total pipeline pressure value. After the mixed gas is boosted to the working pressure by the compressor, the fan ...

Embodiment 2

[0021] This embodiment is a device for recovering active components of multi-component, high-concentration, low-flow, intermittent organic waste gas, such as figure 1As shown, it includes a buffer tank 1, a fan 2, a primary condenser 3, a secondary condenser 4, a tertiary condenser 5, a gas-liquid separation tank 6, a first adsorption tower 7, a second adsorption tower 8, and a third adsorption tower Tower 9, vacuum pump 11, oil storage tank 13 and waste oil pump 14; buffer tank 1 is equipped with organic waste gas inlet, primary condenser 3 is connected with buffer tank 1 organic waste gas outlet through fan 2, primary condenser 3, and secondary condenser 4 and the third-stage condenser 5 are connected in sequence and then connected to the gas-liquid inlet of the gas-liquid separation tank 6, the liquid outlet of the gas-liquid separation tank 6 is connected to the oil storage tank 13, and the gas outlet of the gas-liquid separation tank 6 is connected to the primary condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com