Direct laser pore-forming method

A laser and hole-forming technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of ineffective implementation, low efficiency, complicated manufacturing process, etc., and achieve the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation method of the present invention will be further described below in conjunction with the embodiments.

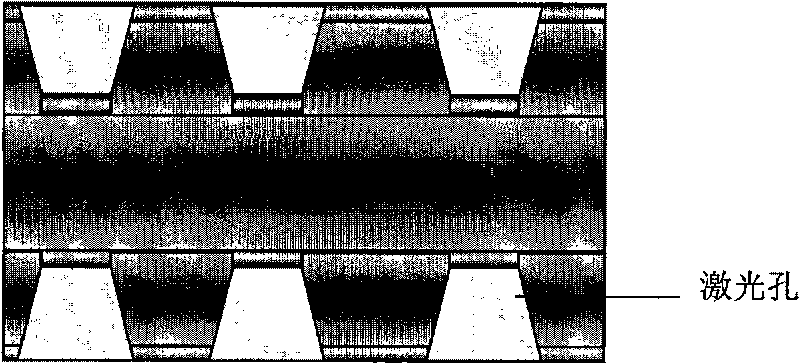

[0022] The idea of the present invention is: before making the optical alignment point, the inner layer circuit is made first, and then pressed, and the optical alignment point is made by X-RAY drilling target. After the hole is formed, the smear should be removed first, and then the black film should be removed, and then transferred to the subsequent process.

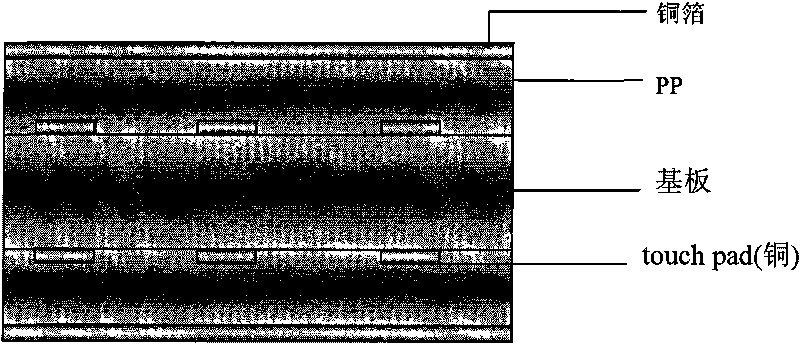

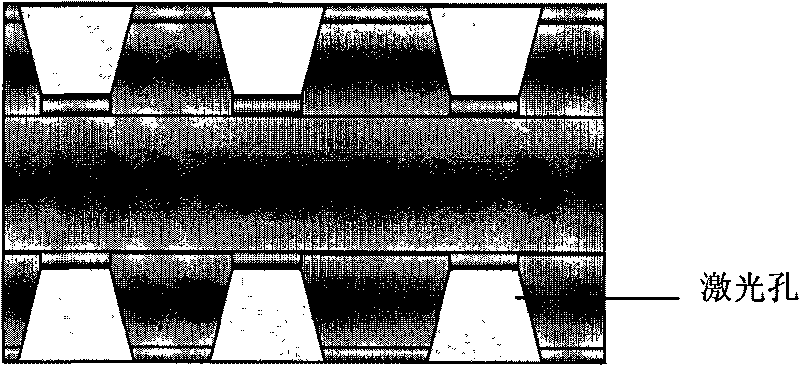

[0023] like figure 1 The above is a schematic diagram of the circuit board before forming holes. The specific method of forming holes is as follows:

[0024] The first step: optical alignment point design.

[0025] Due to the abnormal phenomenon of expansion and contraction in the production process of the sub-outer layer and the lamination, in order to improve the phenomenon of laser partial hole caused by expansion and contraction, the four corners of the board are designed and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Copper thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com