Manufacturing method of packaging substrate based on radio frequency filter

A technology for radio frequency filters and packaging substrates, which is applied to the improvement of the metal adhesion of insulating substrates, the manufacture of multilayer circuits, and the manufacture of printed circuits. Avoid the infiltration of potion, low production cost and strong function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The invention provides a method for manufacturing a package substrate based on a radio frequency filter, comprising the following steps:

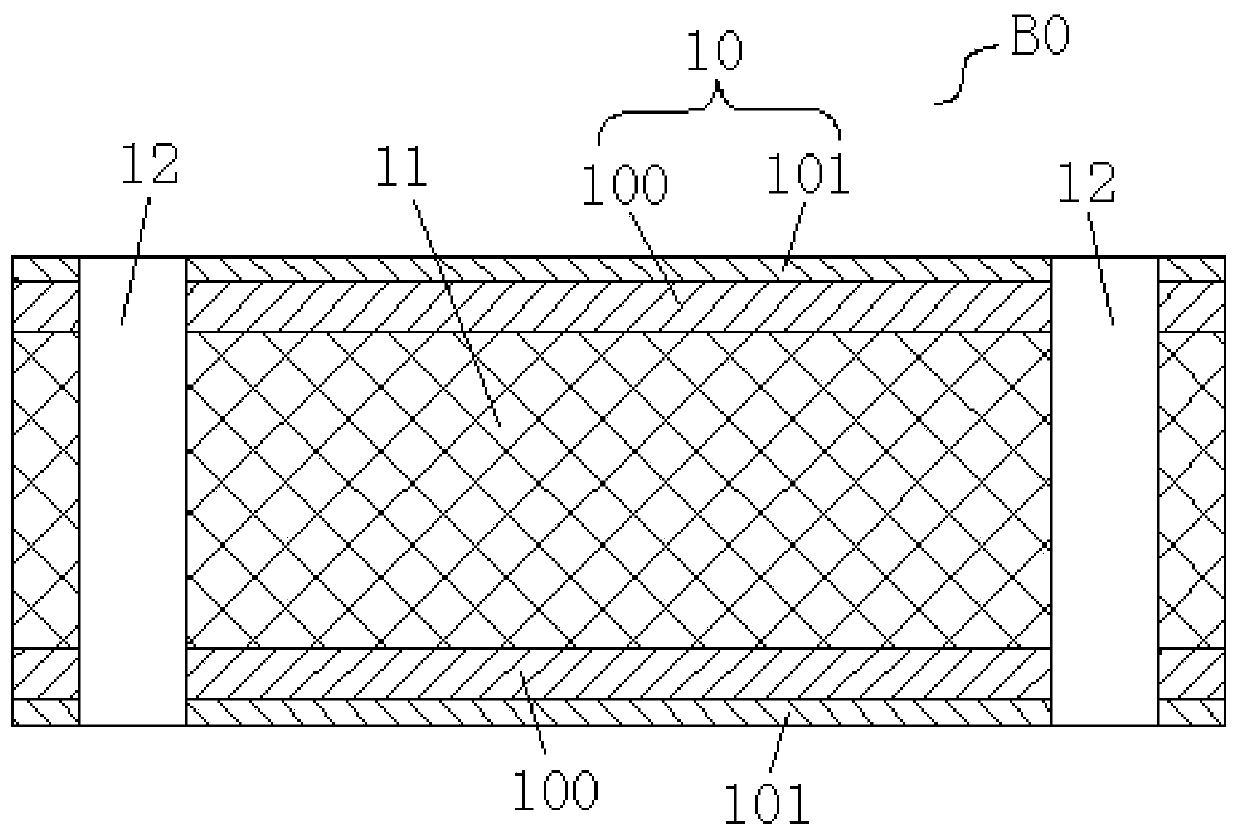

[0033] Step 1), prepare a double-sided copper-clad substrate B0, please refer to the attached figure 1 As shown, the double-sided copper-clad substrate B0 is formed by pressing two ultra-thin carrier copper foils 10 and an auxiliary substrate 11 in the middle, wherein each of the ultra-thin carrier copper foils 10 has a layer A carrier copper foil 100 and a layer of ultra-thin copper foil 101 detachably arranged on the carrier copper foil 100, the ultra-thin copper foil can be deposited on the carrier copper foil by electrodeposition processing , but before the electrodeposition operation, the carrier copper foil should be treated accordingly to ensure that the carrier copper foil and the ultra-thin copper foil can be well separated, and the carrier copper foil 100 is still facing the The auxiliary substrate 11; in addition, an alig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com