Composite material cap-shaped part preparation device with stop blocks and operation method of composite material cap-shaped part preparation device

A technology for composite materials and preparation devices, which is applied in the direction of household components, other household appliances, household appliances, etc., can solve the problems of difficult to ensure the quality of bonding, difficult to ensure the shape of parts, and high requirements for curing molds, so as to reduce the number of times of curing in cans, High practicability, reduced time and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

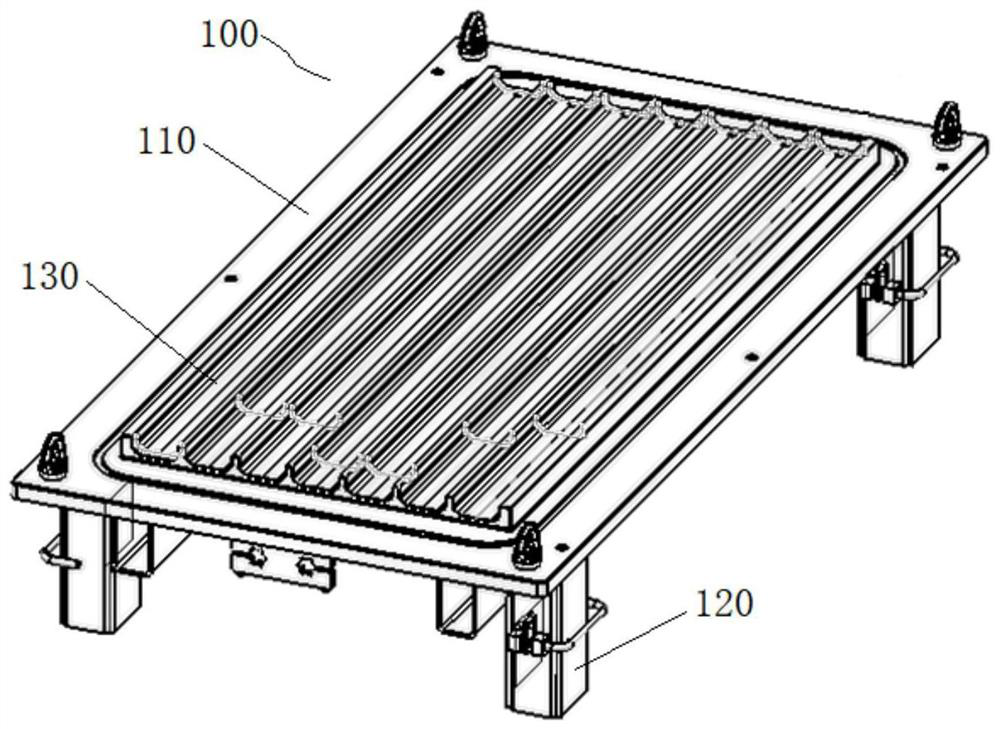

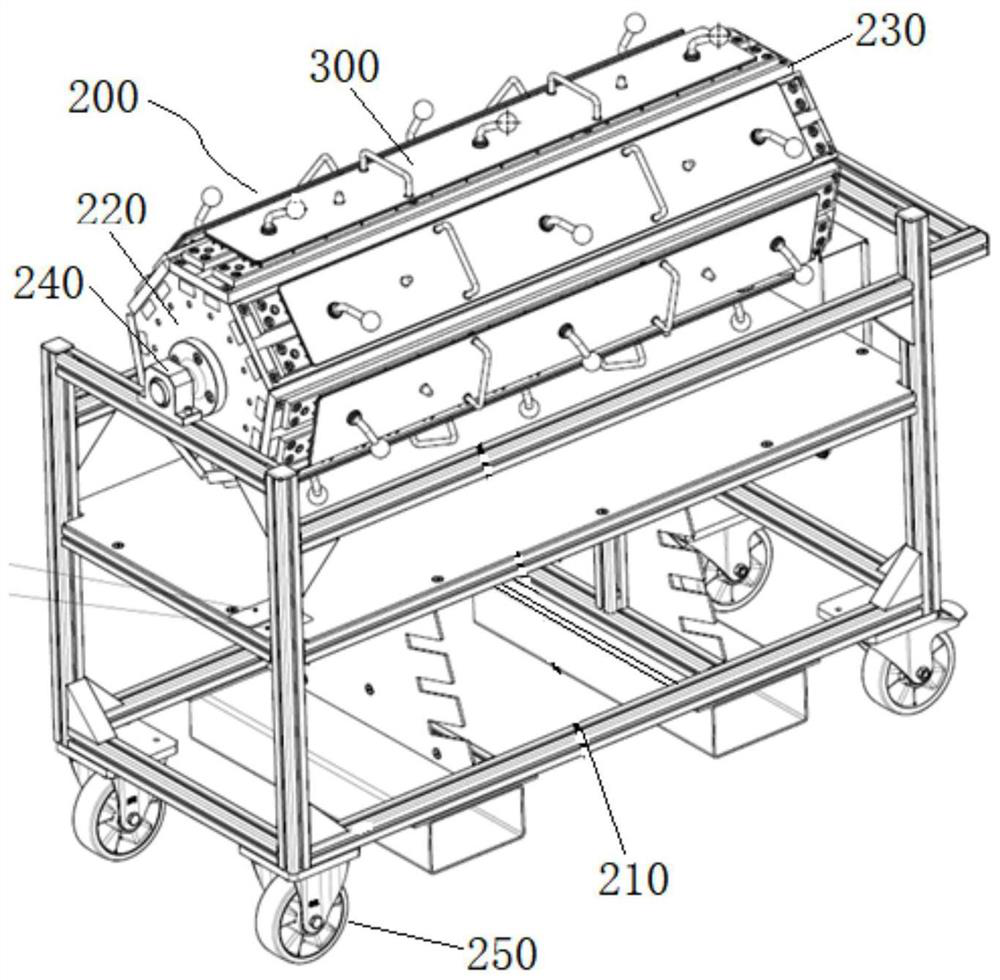

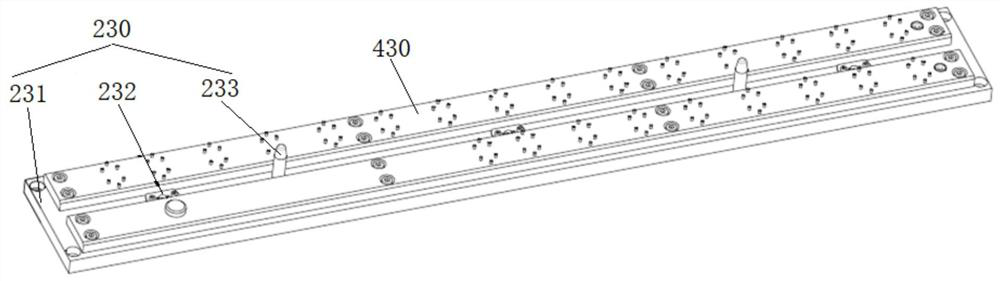

[0044] Such as Figure 1-7As shown, this embodiment provides a device for preparing a composite hat with a stopper, including a lay-up tool 100, a bonding tool 200 and a pressing tool 300. The lay-up tool 100 is used to form multiple U-shaped masks at one time. Leather 410; the bonding tool 200 includes a frame 210, which can be spliced by a plurality of section steels and has high bearing strength. A rotatable multi-faceted cylindrical drum 220 is arranged on the top of the frame 210, and there are multi-faceted cylindrical drums 220. A strip-shaped positioning groove, a plurality of positioning grooves are distributed in a circular array around the axis of the multi-faceted cylindrical drum 220, and a positioning mechanism 230 is arranged in the positioning groove, and the positioning mechanism 230 is used for positioning and installing the stopper 430; The tooling device 300 includes a pressing plate 310 on which a plurality of bolt pressing mechanisms 320 are arranged. T...

Embodiment 2

[0057] Such as Figure 1-7 As shown, the present embodiment provides a method of operating a device for preparing a composite cap with a stopper, comprising the following steps:

[0058] Step S1: forming a plurality of U-shaped skins 410 on the lay-up tool 100;

[0059] Step S2: forming a laminate, using a cutting device to cut the laminate into a plurality of stoppers 430 according to the size requirements, and cleaning the stoppers 430 with a solvent after cutting and drying;

[0060] Step S3: Prepare a sufficient amount of room temperature curing adhesive in proportion;

[0061] Step S4: install the block 430 prepared in step S2 on the base plate 231 of the drum, apply the adhesive prepared in step S3 on the block 430 to form an adhesive layer 420, and then place the U-shaped skin 410 Paste the adhesive layer 420, then align the pressing plate 310 with the positioning column 233 and cover the U-shaped skin 410, and screw the bolt compression mechanism 320 in turn to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com