Edging device for meniscus lens centering and edging method thereof

A centering and edging technology, which is applied in the field of meniscus lens centering and edging devices, can solve the problems of inability to meet the mass production of meniscus lenses, low processing efficiency, and high work intensity, and meet the needs of mass production , Improve the effect of edging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

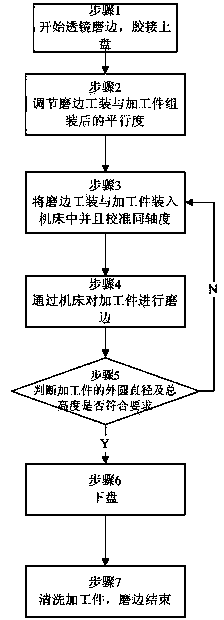

[0044] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0045] Such as Figure 6 As shown, the mechanical method centering is to use a pair of coaxial chucks to clamp the optical parts with elastic force to realize automatic centering. When the parts are just clamped into the chucks, the optical axis of the parts does not coincide with the mechanical axis of the chucks, and the chucks There is only one point of contact between the cutting edge of the end face and the part. At the contact point P, a force F is generated due to the action of the elastic force. The part moves in the S direction until the contact point expands to a circle, the centering force is in a balanced state, the optical axis of the part coincides with the mechanical axis of the chuck, and the purpose of centering is achieved.

[0046] According to lens centering conditions:

[0047] K=︱(D1 / r1±D2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com