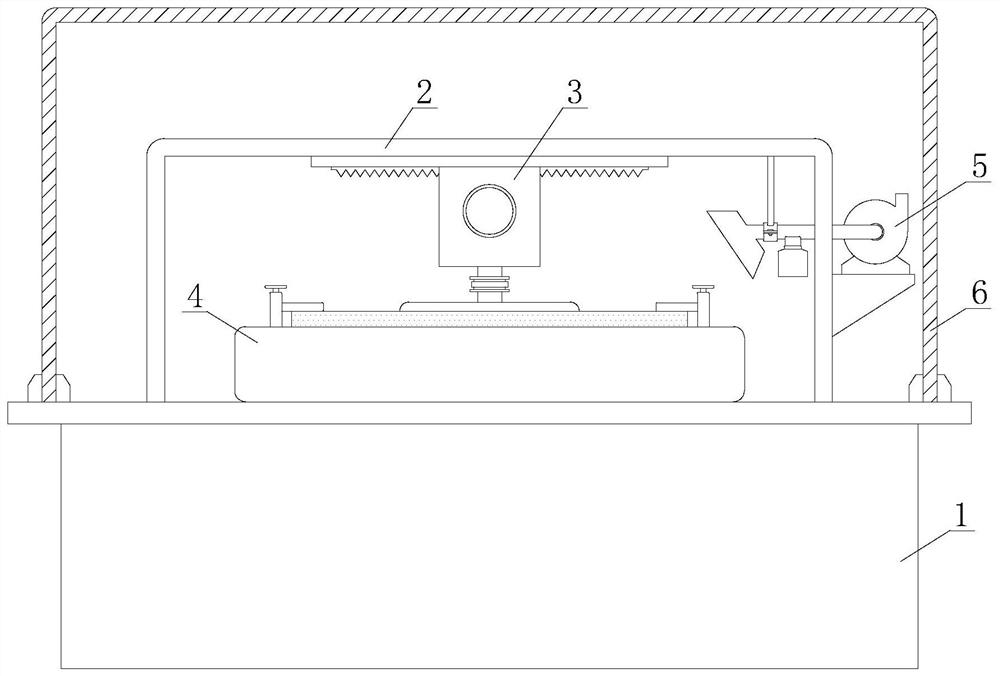

Glass edge grinding device capable of collecting waste residues and implementation method thereof

A glass edging and glass technology, which is applied to grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of low glass edging efficiency, increased operator workload, waste collection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

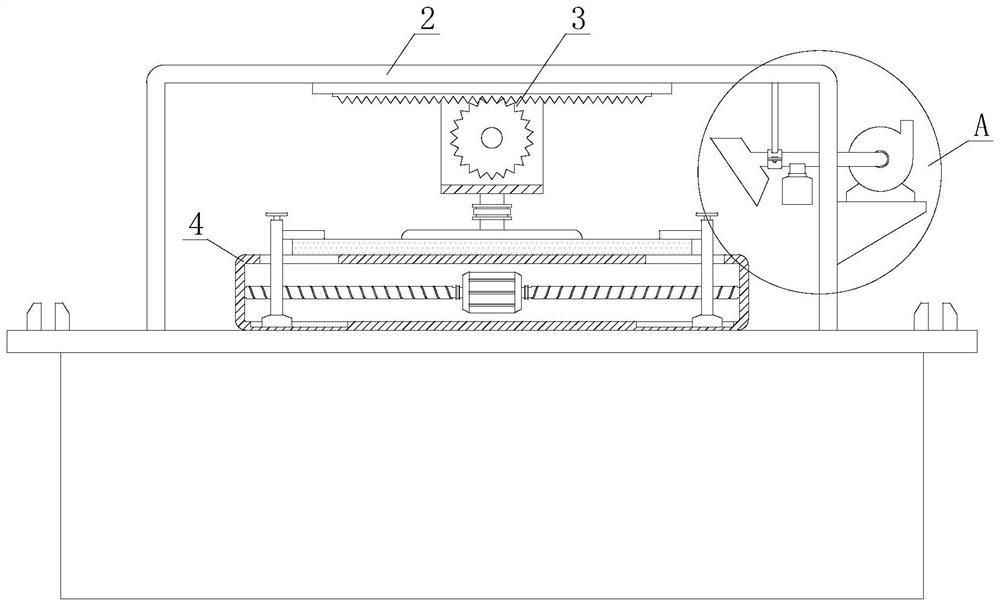

[0036] In order to better demonstrate the implementation process of the glass edging device that can collect waste slag, this embodiment now proposes an implementation method of a glass edging device that can collect waste slag, including the following steps:

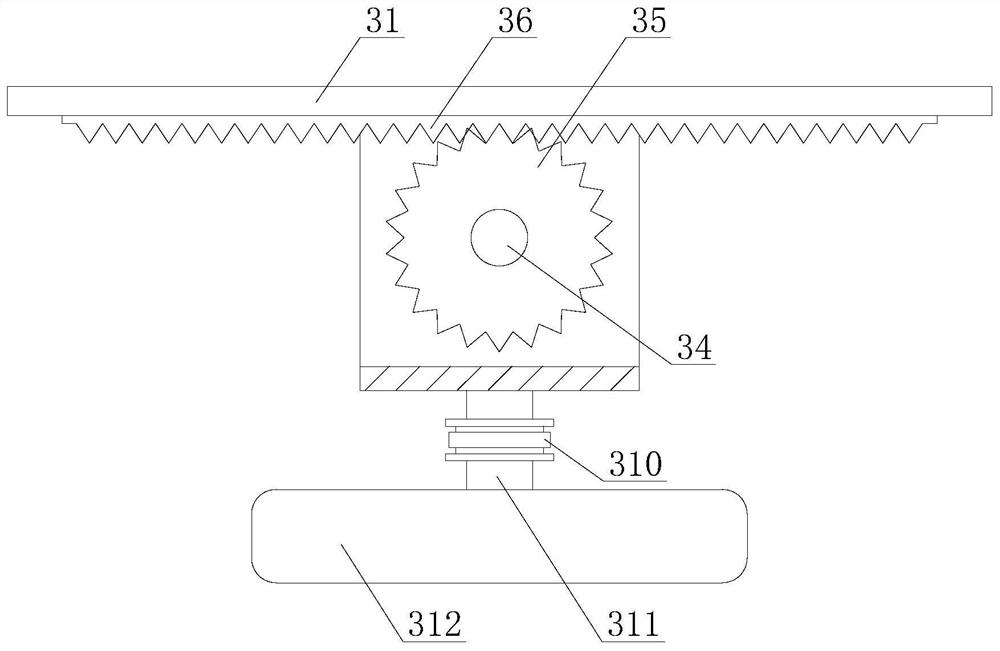

[0037] S1: The glass is placed on the clamping base 41 and the side of the glass is close to the glass edging block 312. The double-axis motor 42 drives the first driving screw 43 and the second driving screw 44 to rotate, so that the adjacent guide slides Seat 451 moves toward each other;

[0038] S2: The hand wheel 4521 drives the third transmission screw 452 to rotate, so that the clamping platen 454 descends on the bar-shaped guide column 453, and the glass is pressed on the clamping base 41 through the clamping platen 454;

[0039] S3: The driving motor 33 drives the first rotating shaft 34 and the transmission gear 35 to rotate, so that the traversing edging slide 32 moves on the fixed base 31, and the glass is ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com