Oil pan assembly for two-stroke horizontally-opposed-piston and opposed-cylinder engine

A technology of horizontally opposed pistons and opposed cylinders, which is applied in the direction of engine lubrication, oil pan, engine components, etc., to achieve the effect of simple internal structure, meeting the needs of mass production, reducing assembly weight and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

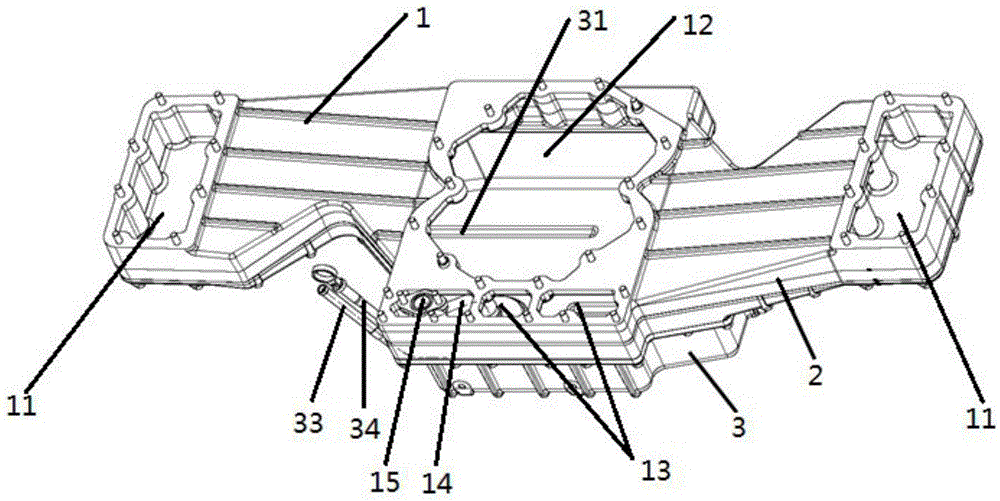

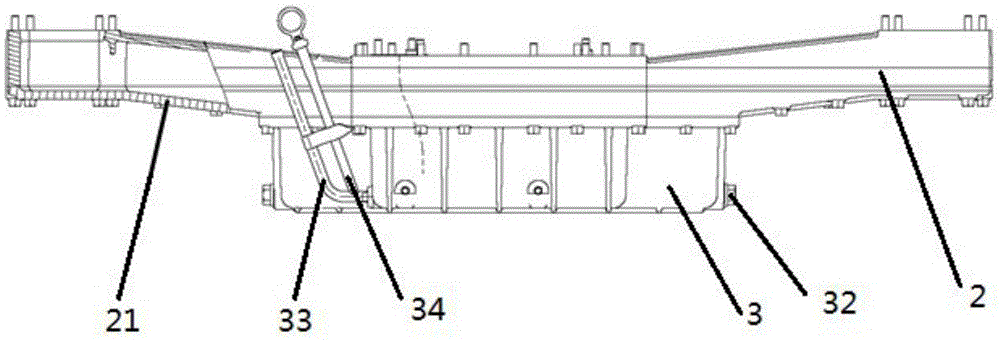

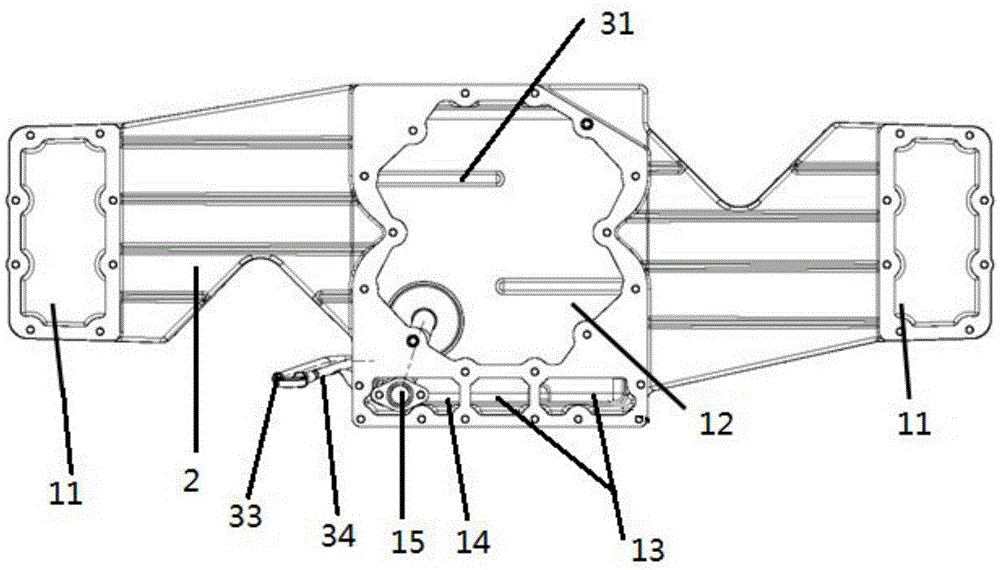

[0034] The upper body 1 of the oil pan is a long plate-like structure, and the two ends of the upper body 1 of the oil pan are even, and the middle part is sunken.

[0035] The oil return ports include: an oil return port 11 for outer piston cooling machine oil, an oil return port 12 for inner piston cooling machine oil and an oil return port 13 for gear chamber machine oil. The outer piston cooling oil return ports 11 are arranged at both ends of the upper body 1 of the oil pan, and are used for the oil return of the outer piston cooling oil. The inner piston cooling machine oil return port 12 is arranged in the middle part of the upper body 1 of the oil pan, and is used for oil return of the inner piston cooling machine. The oil return port 13 of the gear chamber is arranged in the middle of the upper body 1 of the oil pan, on the side of the inner piston cooling oil return port 12. There are several oil return ports 13 in the gear chamber for gear Oil return of indoor mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com