Optical-element washing structure

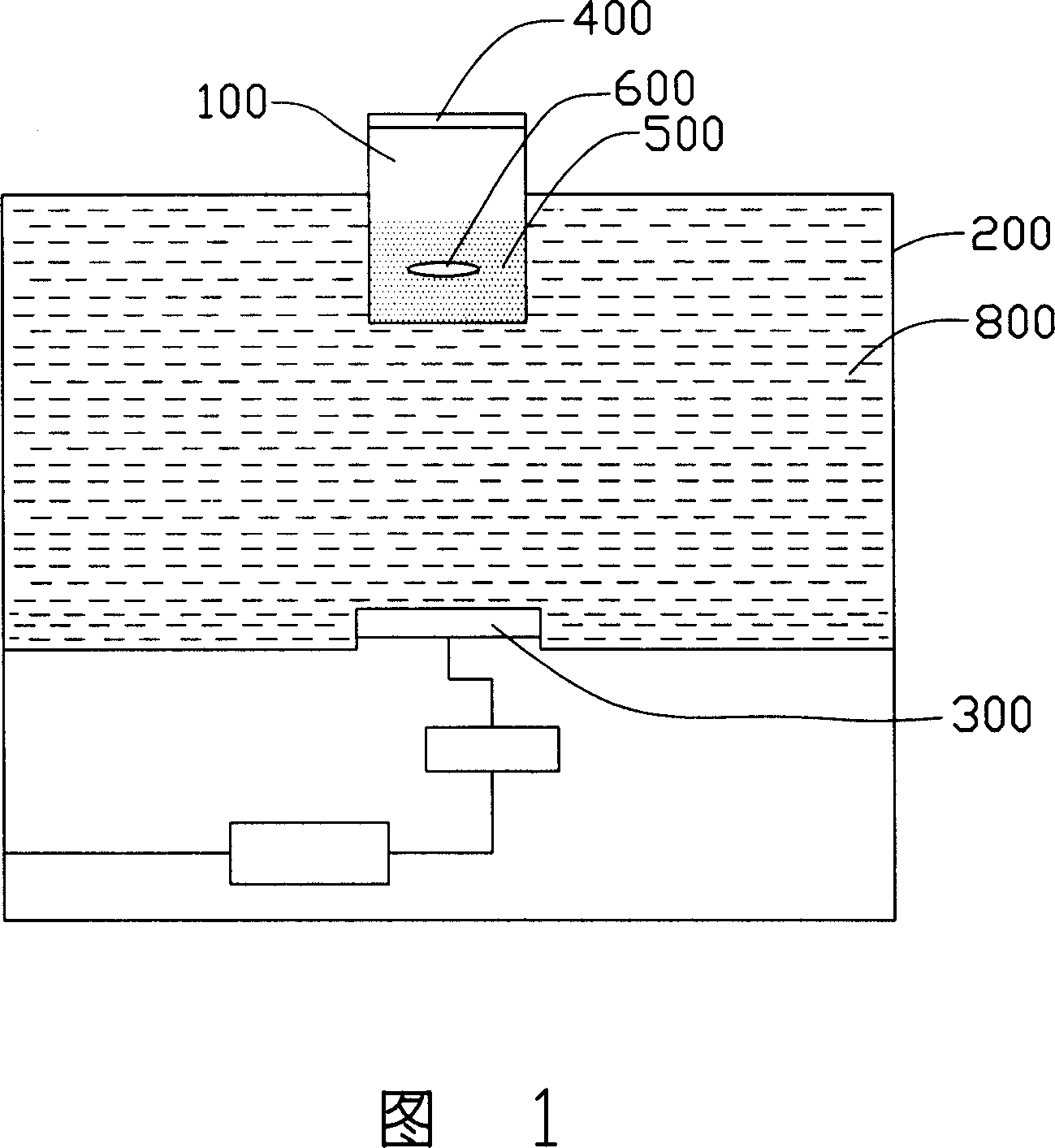

A technology of optical components and clamping structure, applied in optics, glasses/protective glasses, instruments, etc., can solve the problems of difficult cleaning in large quantities and low cleaning efficiency, and achieve the effect of meeting mass production requirements and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

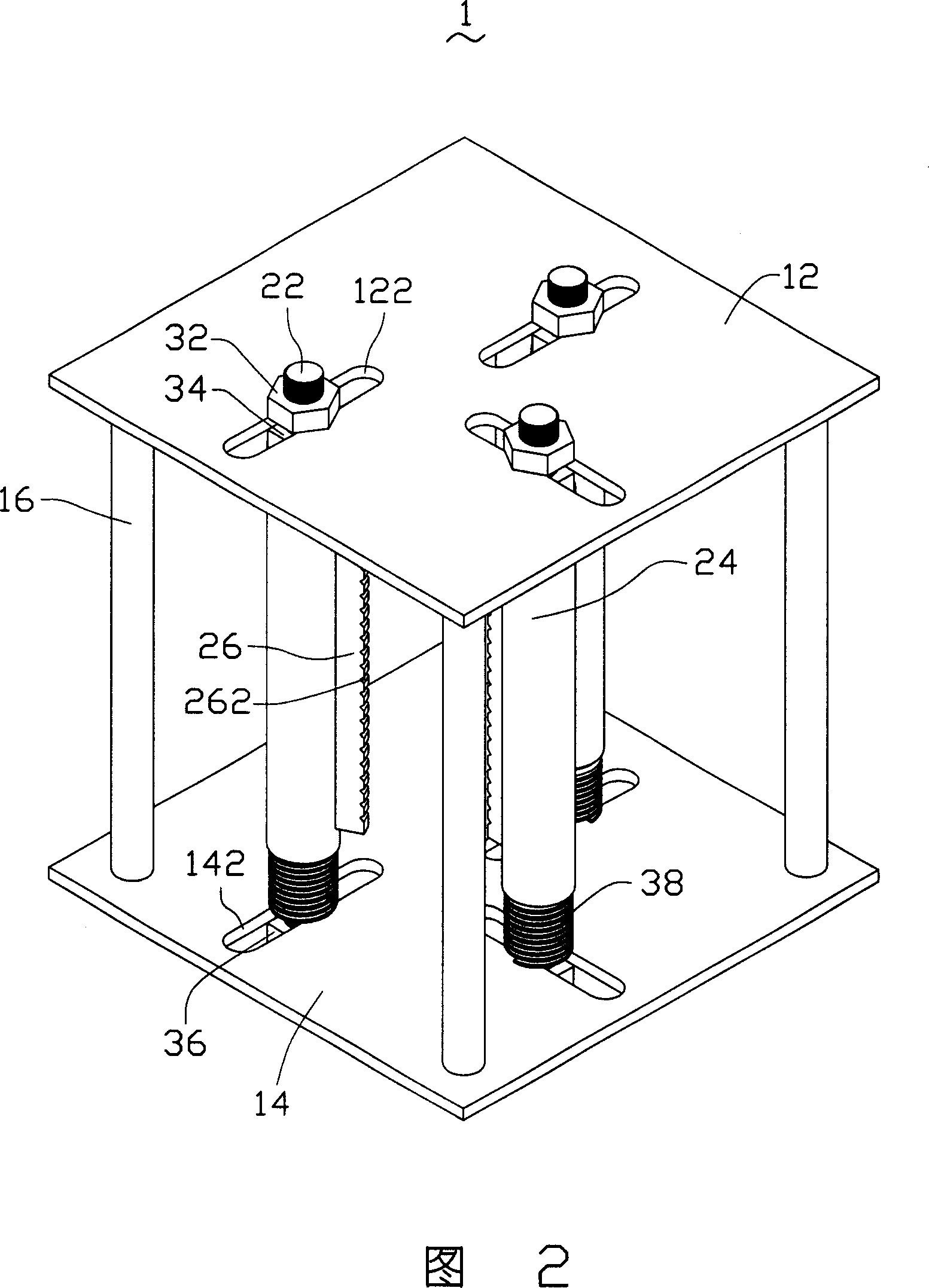

[0014] Please refer to FIG. 2 and FIG. 3 , the optical element cleaning structure 1 according to the first embodiment of the present invention includes a frame (not shown), three supporting devices 20 and three height adjusting devices (not shown).

[0015] The frame includes a square first holding plate 12 , a square second holding plate 14 and a plurality of supporting columns 16 . In this embodiment, a plurality of supporting columns 16 are used to support and connect the first holding plate 12 and the second holding plate 14 . Three elongated through holes 122 are opened on the first holding plate 12 , and the three elongated through holes 122 are arranged in a T shape. Corresponding to the three elongated through holes 122 of the first elongated plate 12 , three elongated through holes 142 are defined on the second holding plate 14 , and the three elongated through holes 142 are also arranged in a T shape.

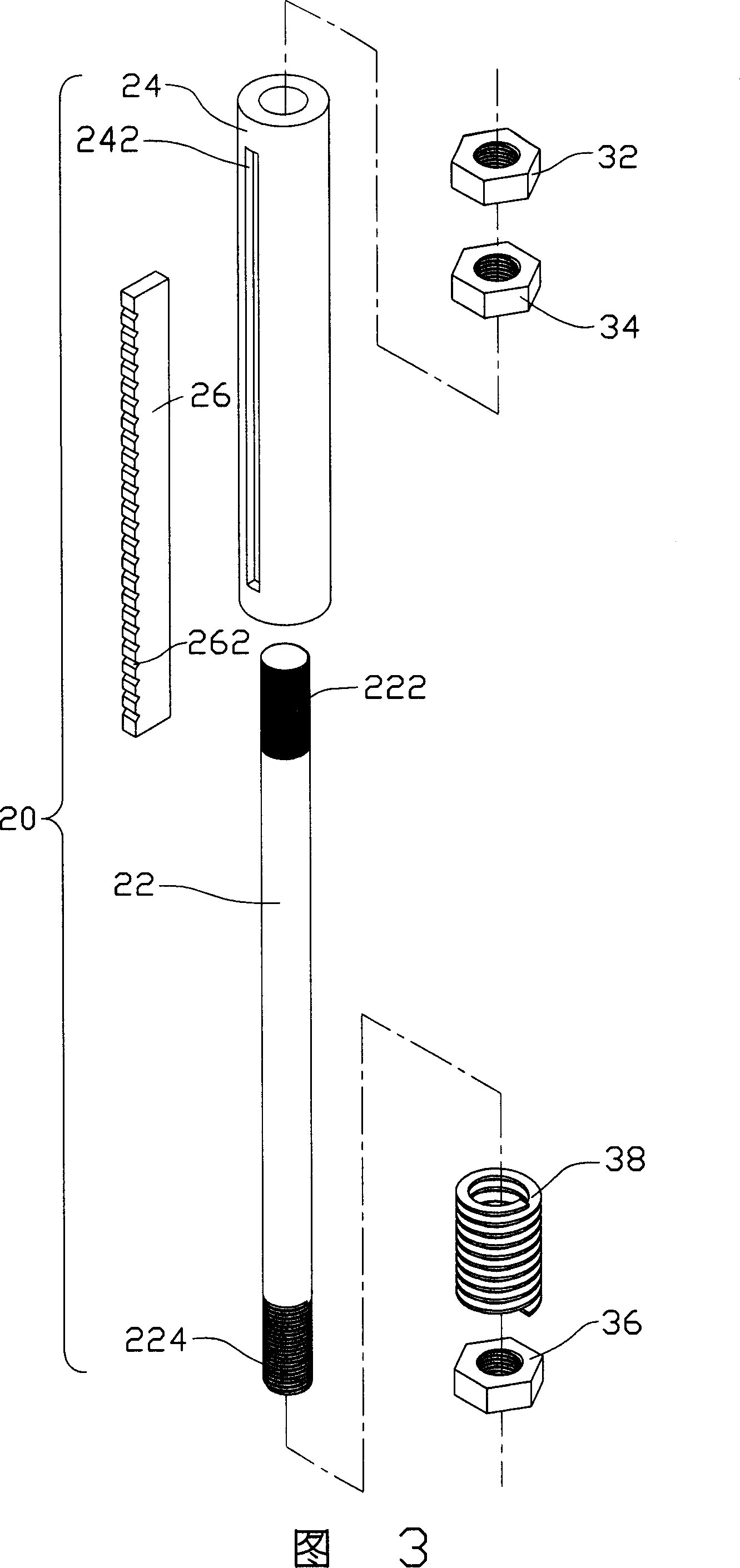

[0016] The carrying device 20 includes a carrying rod 22 , a sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com